HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Flow to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

Sit —Obtaining the Correct Valve Lift in the Water, Pump on Atkinson Wagons.

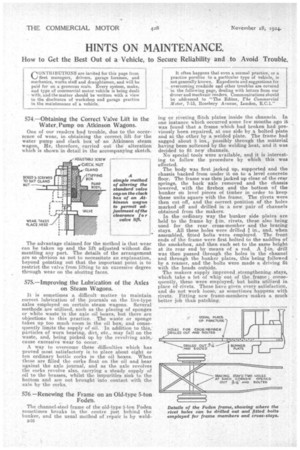

One of our readers had trouble, due to the occurrence of wear, in obtaining the correct lift for the water pump and clack box of' an Atkinson steam wagon. He, therefore, carried out the alteration which is shown in detail in the accompanying sketch.

The advantage claimed for the method is that wear can be taken up and the lift adjusted without dismantling any part. The details of the arrangement are so obvious as not to necessitate an explanation, beyond pointing out that the important point is to restrict the valve from lifting to an excessive degree through wear on the abuttng faces.

575.—Improving the Lubrication of the Axles on Steam Wagons.

It is sometimes a difficult matter to maintain correct lubrication of the journals on the live-type axles .employed on certain steam wagons. Several methods are utilized, such as the placing of sponges or white waste in the axle oil boxes, hut there are objections to this practice. The waste or sponge takes up too much room in the oil box, and consequently limits the supply of oil. In addition to this; particles of worn bearing, dirt, etc., may fall on the waste, and, being picked up by the revolving axle, cause excessive wear to occur.

A way to overcome these difficulties which has proved most satisfactory is to place about eight or ten ordinary bottle corks in the oil boxes. When these are filled the corks float on the oil and bear against the axle journal, and as the axle revolves the corks revolve also, carrying a steady supply of oil to the brasses, whilst the impurities sink to the bottom and are not brought into contact with the axle by the corks.

576—Renewing the Frame on an Old-type 5-ton Foden.

The channel-steel frame of the old-type 5-ton Iroden sometimes breaks in the centre just behind the bunker, and the usual method of repair is by weld

B46

ing or riveting flitch plates inside the channels. In one instance which occurred some few months ago it was found that a frame which had broken had previously been repaired, at one side by a bolted plate and at the other by a welded plate. The frame had sagged about a ins., possibly through the material having been softened by the welding heat, and it was decided to fit newchannels.

No special tools were available, and it is interesting to follow the. procedure by which this was effected.

The body was first jacked up, supported and the chassis backed from under it on to a level concrete floor. The frame was then jacked up clear of the rear springs, the back axle removed and the chassis lowered, with the firebox and the bottom of the bunker on level pieces of timber in order to keep these units square with the frame. The rivets were then cut off, and the correct position of the holes marked off and drilled in a new pair of channels obtained from the makers.

In the ordinary way the bunker side plates are held to tho frame by 1-in. rivets, these also being used for the rear cross-member and the bracing stays. All these boles were drilled in., and, when assembled, fitted bolts were employed. The front ends of the frame were first bolted to the saddles of the smokebox, and then each set to the same height at its rear end by means of a rod. A fin, drill was then passed through the holes in the channel and through the bunker plates, this being followed by a reamer, and the bolts were made a driving fit with the heads outside.

The makers supply improved strengthening stays, which take a lot of whip out of the. frame: consequently, these were employed,' but bolts utilized in place of-rivets. These have given every satisfaction, and do not work loose, as sometimes happens with rivets. Fitting new frame-members makes a much better job than patching.