A LIGHTWEIGHT single-deck bus, incorporating a number of unusual features including

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

rubber suspension, has recently completed 15,000 miles on the Kelso. Berwick route of Scottish Omnibuses, Ltd. The designer is Mr. R. Dawson, chief engineer of the operating company.

Economies in operation and maintenance were two of the objects behind the design and the vehicle may well provide a solution to the problem associated with the many rural services on which it has, of recent years, been increasingly difficult even to equate receipts with operating expenses.

Rubber Suspension

Scottish Omnibuses, Ltd., have produced a comfortable 32-seater, adaptable for one-man operation; it is 24 ft. long and 7 ft. 9 in. wide. Leg room is above the necessary minimum and the width permits reasonable space for eight standing passengers.

A new type of rubber suspension has proved of assistance in reducing weight and has introduced the important feature of graduated resistance as the Toad increases. Thus the design aims to meet the wide loading fluctuations so often encountered in rural areas.

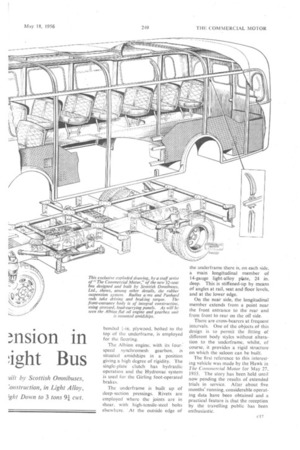

Integral construction is a feature of the design and practically the entire body, including the under frame, is of light alloy. Unladen, the machine registers 3 tons 9+ cwt. and the achievement of so low a weight has been partly assisted by the use of an Albion flat four-cylindered 60 b.h.p. oil engine with four-speed synchromesh gearbox.

Economy in Fuel

Despite the various economies outlined, test records suggest that the operational performance is ,equal to that of heavier machines, whilst fuel consumption is, of course, substantially lower.

Quite apart from its origin in the works of Scottish Omnibuses, the lightweight bus is substantially a Scottish product. The power unit originates from Glasgow, as do the conventional axles which have beeti specially produced by Albion Motors, Ltd. The main body components have come from the British Aluminium Co., Ltd., at Falkirk.

An important exception is the rubber suspension system which has been evolved in conjunction with the Special Products Division of the Dunlop Rubber Co., Ltd. Whilst the design has been produced primarily

c16 to meet the needs of the operators, they will be willing to co-operate with coachbuilding concerns who may be interested in the design.

The rubber springing unit, which forms the heart of the suspension, is understood to have been the subject of experiment by experts in the application of natural rubber over a considerable period. In overcoming a number of problems, it may welI be that the designers of the unit in question have received some inspiration from components that have proved sUccessful in aircraft practice.

Initially, a new form of springing was sought, both with a view to weight reduction and with the aim of securing a suitable variable suspension rate, a particularly desirable feature in view of the vehicle's having a higher ratio of loaded weight to unloaded weight than is customary with heavier passenger units.

Driving and Braking Torque

As front and rear axles are positively located by radius arms and Panhard rods that take the driving and braking torque, the rubber units are required to carry only the weight of the vehicle. Theyare stated to weigh less than the coil springs used on the independent suspension systems of typical large private cars. Bearing in mind that economy was the prime motive of the design, it was decided to avoid the extra cost and complication that would probably be involved by the use of independent suspension.

Compression of the rubber springing unit is not in direct proportion to the load carried, but resistance becomes greater as the weight increases. As it is anticipated that a vehicle of this nature will spend much of its time running fairly light, this introduces an important feature as axle movement will be relatively free without the vibration being transmitted to the body.

Insulation of the suspension system from the rest of the vehicle by means of rubber should also be an aid to the reduction of road noise as well as reducing the need for lubrication. The system is stated to be particularly effective when cornering, as the stiffening effect produces a resistance to "'heeling."

The design provides for an integral construction front-entrance body. The panelling and framing of the body are riveted as all panels are

stressed and load-carrying. Location of the alloy-steel seat frames is such as to provide a link between the sides of the vehicle and the longitudinal frame members. Resin

bonded plywood, bolted to the

top of the underframe, is employed for the flooring.

The Albion engine, with its four: speed synchromesh gearbox, is situated amidships in a position giving a high degree of rigidity. The single-plate clutch has hydraulic operation and the Hydrovac system is used for the Girling foot-operated brak es.

The underframe is built up of deep-section pressings. Rivets are employed where the joints are in shear, with high-tensile-steel bolts elsewhere. At the outside edge of the underframe there is, on each side, a main longitudinal member of 14-gauge light-alloy plate, 24 in. deep. This is stiffened-up by means of angles at rail, seat and floor levels, and at the lower edge.

On the neai side, the longitudinal member extends from a point near the front entrance to the rear and from front to rear on the off side.

There are cross-bearers at frequent intervals. One of the objects of this design is to permit the fitting of different body styles without alteration to the underframe, whilst, of course, it provides a rigid structure on which the saloon can be built.

The first reference to this interesting vehicle was made by the Hawk in The Commercial Motor for May 27, 1955. The story has been held until now pending the results of extended trials in service, After about five months' running, considerable operating data have been obtained and a practical feature is that the reception by the travelling public has been enthusiastic.