The Management of Motor-Wagon Boilers.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

It is well known to engineers that the smaller the boiler the more important becomes the question of water supply. With a large boiler for stationary work the length of the water-gauge glass may be 2k., and a variation of 6 or 8in. may reasonably be permitted without affecting either the efficiency of the boiler or endangering the fire-box, whereas, in a motor-wagon boiler, the gauge glass is sometimes 41n. long, and the safe variation of water level but half that much. Further, the motor-wagon boiler is so small that the water is up or down in a minute or two. In a vertical multitulaular boiler as used on the majority of motor wagons, or a water-tube boiler with drum at top, an inch of water in the glass represents only three gallons, whilst in some types it only represents half this volume, To contrast this with the other extreme, a double-ended marine boiler may take x2ogals. to raise the water in the glass tin. To those unfamiliar with steam boilers, the importance of the water level in the boiler is not apparent. Suffice it to say that a boiler, primarily, has an outside shell, with the fire-box entirely inside it and surrounded on all sides by water; further, there is sometimes a combustion chamber and a mass of tubes, through which the flames pass and give up their heat to the water, also inside the shell. On one side of the fire-box plates, or the tubes, is a hot fire or flame, on the other side water, and it is impossible for the steel to be heated to a temperature much above that of the boiling point for the pressure used, as it parts with its heat very quickly. If, however, the level gets so low that there is no water over the are-box crown, the plate will get red hot in a few minutes, and, when hot, will be soft enough to yield to the steam pressure, with the result that the fire-box will collapse. Similarly, if the water level is low enough to uncover a horizontal tube, it will get red hot, and,

though its shape will prevent immediate collapse, the heat will destroy its nature and cause it to leak. There is not the same danger with vertical tubes, and, further, as the hot gases have parted with much of their heat in passing through the tubes, there is not so much danger of overheating at the chimney end as immediately over the fire itself. It is now the universal practice to lit a so-called " fusible " plug in the crown of the fire-box, the centre of the plug being filled with lead or white metal, which melts at a comparatively low temperature. If, therefore, the lirebox crown is not covered by water, the fusible plug melts out at once and the steam escapes into the fire-box, putting the fire out. Consequently, nowadays, one never hears of a fire-box collapsing, arid it is becoming an uncommon experience for a driver even to have to report that " his plug has burnt out,'' but there should always be a spare fusible plug in the tool box.

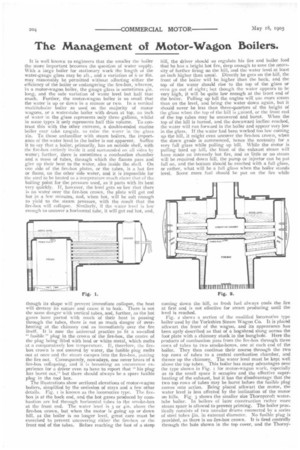

The illustrations show sectional elevations of motor-wagon boilers, simplified by the omission of stays and a few other details. Fig. i is known as the locomotive type. The firebox is at the back end, and the hot gases produced by combustion are led through horizontal tubes to the smoke-box at the front end. The water level is 3 or 4in, above the fire-box crown, but when the motor is going up or down hill, as the boiler is no longer level, great care must be exercised to prevent uncovering either the fire-box or the front end of the tubes. Before reaching the foot of a steep hill, the driver should so regulate his tire and boiler feed that he has a bright hot fire, deep enough to save the necessity of further tiring on the hill, and the water level at least an inch higher than usual. Directly he gets on the hill, the front of the boiler will be higher than the back, and the Lop of the water should rise to the top of the glass or even go out of sight ; but though the water appears to be very high, it will be quite low enough at the front end of the boiler. Pulling up hill the engine will use more steam than on the level, and bring the water down again, but it should never be less than three-quarters of the height of the glass when the top of the hill is gained, or the front end of the top tubes may be uncovered and burnt. When the top of the hill is turned, and the downward incline reached, the water will run forward in the boiler and appear very low in the glass. If the water had been worked too low coming up the hill, it might even uncover the fire-box crown, when the down grade is commenced, hence the necessity for a very full glass while pulling up hill. While the motor is pulling hard up hill, the blast of the exhaust steam will have made an intensely hot fire, and as little or no steam will be required down hill, the pump or injector can be put full on and the bottom should be reached with a full glass, or rather, what will be a full glass when the boiler stands Level. Some more fuel should be put on the fire while coming down the hill, as fresh fuel always cools the lire at first and is not effective for steam producing until the level is reached.

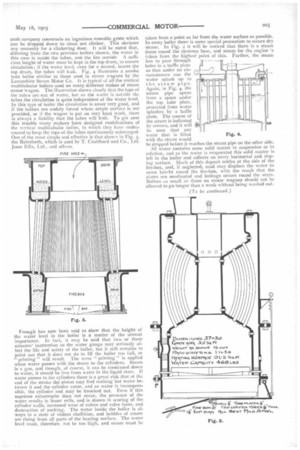

Fig. 2 shows a section of the modified locomotive type boiler used by the Yorkshire Steam Wagon Co. It is placed athwart the front of the wagon, and its appearance has been aptly described as that of a hogshead slung across the foot plate with a chimney stuck in the bunghole. Here the products of combustion pass from the fire-box through three rows of tubes to two smoke-boxes, one at each end of the boiler. They then continue their course through the two top rows of tubes to a central combustion chamber, and thence up the chimney. The water level must be kept well above the top tubes. This boiler has many advantages over the type shown in Fig, i for motor-wagon work, especially as to the small space it occupies and the effective superheating of the exhaust, but it has the disadvantagethat the two top rows of tubes may be burnt before the fusible plug comes into action. Being placed athwart the motor, the water level is less affected by the inclination of the motor on hills. Fig. 3 shows the smaller size Thornycroft watertube boiler. In boilers of later construction rather more steam space is allowed to prevent priming. The boiler practically consists of two annular drums connected by a series of steel tubes'fin. in external diameter. No fusible plug is provided, as there is no fire-box crown. It is fired centrally through the hole shown in the top cover, and the Thorny croft company constructs an ingenious movable grate which can be dropped down to clean out clinker. This obviates any necessity for a clinkering door. It will be noted that, differing from the two previous boilers shown, the water in this case is inside the tubes, and the fire outside A sufficient height of water must be kept in the top drum, to ensure circulation; if the water level, even for a second, leaves the top drum, the tubes will leak. Fig. 4 illustrates a smoke tube boiler similar to those used in steam wagons by the Lancashire Steam Motor Co. It is typical of all the vertical rnultitubular bailers used on many different makes of steam motor wagon. The illustration shows clearly that the tops of the tubes are out of water, but as the water is outside the tubes the circulation is quite independent of the water level. In this type of boiler the circulation is never very good, and if the boilers are unduly forced where ample surface is not provided, or if the wagon is put on very hard work, there is always a liability that the tubes will leak. To get over this trouble many makers have designed modifications of the vertical multitubular boiler, in which they have endeavoured to keep the tops of the tubes continuously submerged. One of the most simple and effective is that shown in Fig, 5, the Balmforth, which is used by T. Coulthard and Co., Ltd. Jesse Ellis, Ltd., and others.

Enough has now been said to show that the height of the water level in the boiler is a matter of the utmost importance. In fact, it may be said that two or three minutes' inattention to the water gauge may seriously affect the life and safety of the boiler, but it still remains to point out that it does not do to fill the boiler too full, or " priming " will result. The term " priming" is applied when water passes with the steam to the cylinders. Steam is a gas, and though, of course, it can be condensed down to water, it should be free from water in the liquid state. If water passes to the cylinders there is a great risk that at the end of the stroke the piston may find nothing but water between it and the cylinder cover, and as water is incompressible, the cylinder end may be knocked out. Even if this supreme catastrophe does not occur, the presence of the water results in lesser evils, and is shown in scoring of the cylinder walls, increased wear of valves and valve faces, and destruction of packing_ The water inside the boiler is always in a state of violent ebullition, and bubbles of steam are rising from all parts of the heating surface. The water level must, therefore, not be too high, and steam must be

taken from a point as far from the water surface as possible. In every boiler there is some special precaution to secure dry steam. In Fig. 2 it will be noticed that there is a steam dome round the chimney base, and steam for the engine is taken from the highest point of this. Further, the steam has to pass through holes in a baffle plate so that under no circumstances can the water splash up to the steam pipe. Again, in Fig. 4, the steam pipe opens from a space under the top tube plate, protected from water splashes by a baffle plate. The course of the steam is indicated by arrows, and it will be seen that any water that is lifted with the steam would be dropped before it reaches the steam pipe on the other side.

All water contains some solid matter in suspension or in solution, and as the water is evaporated this solid matter is left in the boiler and collects on every horizontal and sloping surface. Much of this deposit settles at the side of the fire-box, and, if neglected, mud may displace the water to some beiplit round the fire-box, with the result that the plates are overheated and leakage occurs round the stays. Boilers as small as those on motor wagons should not be allowed to go longer than a week without being washed out.

Pig. 4.