Pattern of tyre specs

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

TO MOST OPERATORS tyres are merely the round black things at the corners of the truck which cost a fortune to replace.

The major cause for concern among these fleet owners — be it for two or 200 vehicles — is the total yearly cost and specifying the right tyre for the job can go a long way towards controlling this cost.

I recently had a long discussion with Arthur Hughes, truck tyre sales manager of Goodyear, on the merits and demerits of the various types of tyre construction.

If we avoid for the moment the arguments over radial or cross-ply construction and concentrate on the tread pattern only, we find that there are three basic types of tyre Road pattern; El On/off-road pattern; E Off/on-road pattern The first one is selfexplanatory while the second is described as a tyre for 90 per cent on the road and 10 per cent off. The third pattern is the reverse of the second intended for 90 per cent off-road use.

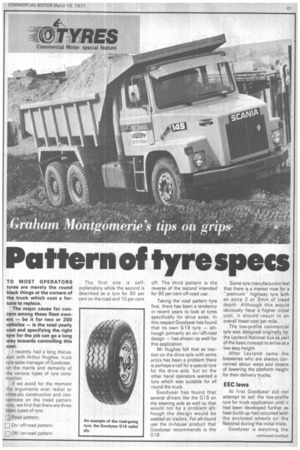

Taking the road pattern tyre first, there has been a tendency in recent years to look at tyres specifically for drive axles. In this respect Goodyear has found that its own G19 tyre — although primarily an on/off-road design — has shown up well for this application.

Mr Hughes felt that as traction on the drive axle with some artics has been a problem there is perhaps a call for a special tyre for the drive axle, but on the other hand operators wanted a tyre which was suitable for all round the truck.

Goodyear has found that several drivers like the G19 on the steering axle as well so that would not be a problem although the design would be wasted on trailers. For all-round use the in-house product that Goodyear recommends is the G18.

Some tyre manufacturers feel that there is a market now for a -premiumhighway tyre with an extra 2 or 3mm of tread depth. Although this would obviously have a higher initial cost, it should result in an overall lower cost per mile.

The low-profile commercral tyre was designed originally for the Leyland National bus as part of the basic concept to arrive at a low step height.

After Leyland came the breweries who are always concerned about ways and means of lowering the platform height for their delivery trucks.

EEC laws

At first Goodyear did not attempt to sell the low-profile tyre for truck application until it had been developed further as heat build-up had occurred with the enclosed wheels on the National during the initial trials..

Goodyear is watching the

progress of the proposed EEC regulation on height which recommends a maximum of 4.0m (1 3f t 15/ain). This can raise problems for operators especially when engaged in container traffic so, depending on whether a higher axle limit is adopted at the same time, the low-profile tyre could become extremely important.

Many years ago there was a tremendous upheaval on the tyre market when the truck weight and speed regulations were altered. Before that the standard haulage machine was an eight-wheeler with no engine, no brakes and a 20mph plate on the back. With these trucks, 90,000 miles per tyre was commonplace.

When the 32-tonners and the motorways came in, the tyre mileages per tread fell like a stone. At about the same time radials were coming in which lifted the mileage from around 30,000 to nearer 70,000.

On the often thorny subject of remoulds Mr Hughes said that as a general rule an operator would not make an overall tyre saving by using such tyres on long fast runs as there was a much higher risk of separation. "The application of remoulds has not been too sensible in the past. With some operations it has been effective but with others it has put the cost up." He stressed that the performance of a remould was dependent upon the condition of the carcass and if an operator wanted to use them for long haul service then it was essential to specify premium remoulds.

For a tipper running on a rough surface, the cheapest possible remoulds were the answer as any long-wearing properties would be negated by the almost unavoidable damage to the carcass on site.

On the other hand, according

to Mr Hughes, any operators using remoulds on Middle East or TIR runs were -out of their tiny minds."

Tankers first

Super singles were first used on tankers 'with the aim of saving a few vital hundredweight. When the first 6,000gal tanker was built it needed super singles to be able to run fully laden without going over the 32-ton limit.

But super singles have their disadvantages as well. It is not possible to carry a spare (equivalent to two normal tyres in weight) or if it is possible under he maximum gcw then the iperator has no need to go for singles in the first place.

Punctures on the road can cause problems as many tyre services are reluctant to stock singles.

Another application for the single is on site vehicles. There is no risk of trapping rocks between the wheels as happens with twins and they cut down on the amount of mud spread on the highway for the same reason. On very soft ground, the effective tread width can be dramatically reduced by the earth getting squeezed out at the edges.

With twin wheels this can happen at four edges but on a single it can only occur at two edges so the effective tread width is much greater.

Of the total truck tyre sales per year, probably 70 per cent is now of the radial variety because of the extra mileage which can be obtained.

However, for several applications the cross-ply design still has its uses. For local authority operation with municipal vehicles engaged in stop/start work. the side-walls wear out before the tread because of fairly frequent kerb scrubbing. This is also true for local delivery vans and, to a certain extent, for some tipper applications as well.

As far as the Goodyear marketing strategy goes, there does not seem to be any reason for not specifying radials these days except for the case I have just mentioned. In Arthur Hughes' words "I think the days of the cross-ply truck tyre are starting to get a little bit numbered.'

One-piece wheel

Compared with the car and aircraft markets, trucks were the last to go tubeless. One of the reasons was the lack of a suitable wheel, but eventually the one-piece wheel won the day because it was lighter and had less parts. Initially the tyre fitters didn't like them, but this changed once they got used to them.

Arthur Hughes thought the move to .the tubeless tyre was something to be applauded -he was only surprised that the move had not been more rapid.. Goodyear in general recommends the tubeless tyre, but it must be an original equipment fitting as it can't use the same wheel as a tubed tyre.