Four arguments for that carry a relli truck tyres ot of weight.

Page 106

Page 107

If you've noticed an error in this article please click here to report it so we can fix it.

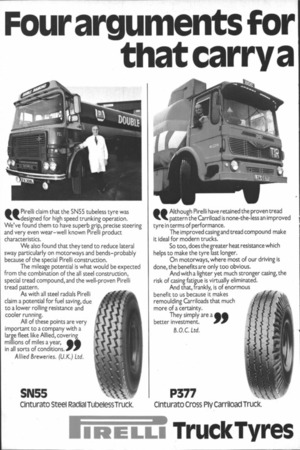

to Pirelli claim that the SN55 tubeless tyre was mh.designed for high speed trunking operation. We've found them to have superb grip, precise steering and very even wear-well known Pirelli product characteristics.

We also found that they tend to reduce lateral sway particularly on motorways and bends-probably because of the special Pirelli construction.

The mileage potential is what would be expected from the combination of the all steel construction, special tread compound, and the well-proven Pirelli tread pattern.

As with all steel radials Pirelli claim a potential for fuel saving, due to a lower rolling resistance and cooler running.

All of these points are very important to a company with a large fleet like Allied, covering millions of miles a year, ay in all sorts of conditions. drir

Allied Breweries. (U.K.) Ltd.

fte Although Pirelli have retained the proven tread pattern the Carriload is none-the-less an improved tyre in terms of performance.

The improved casing and tread compound make it ideal for modern trucks.

So too, does the greater heat resistance which helps to make the tyre last longer. On motorways, where most of our driving is done, the benefits are only too obvious. And with a lighter yet much stronger casing, the risk of casing fatigue is virtually eliminated. And that, frankly, is of enormous benefit to us because it makes remoulding Carriloads that much more of a certainty.

They simply are a', better investment.

B.O.C. Ltd.

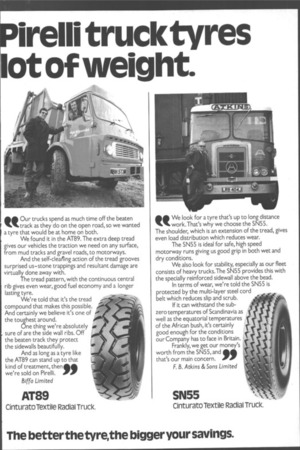

41.0 Our trucks spend as much time off the beaten ‘.track as they do on the open road, so we wanted a tyre that would be at home on both.

We found it in the AT89. The extra deep tread gives our vehicles the traction we need on any surface, from mud tracks and gravel roads, to motorways.

And the self-cleaning action of the tread grooves surprised us—stone trappings and resultant damage are virtually done away with.

The tread pattern, with the continuous central rib gives even wear, good fuel economy and a longer lasting tyre.

We're told that it's the tread compound that makes this possible. And certainly we believe it's one of ••• the toughest around. /111k One thing we're absolutely sure of are the side wall ribs. Off the beaten track they protect the sidewalls beautifully.

And as long as a tyre like the AT89 can stand up to that kind of treatment, then we're sold on Pirelli.

Biffa Limited

We look for a tyre that's up to long distance work.That's why we choose the SN55.

The shoulder, which is an extension of the tread, gives even load distribution which reduces wear.

The SN55 is ideal for safe, high speed motorway runs giving us good grip in both wet and dry conditions. We also look for stability, especially as our fleet consists of heavy trucks.The SN55 provides this with the specially reinforced sidewall above the bead. In terms of wear, we're told the SN55 is protected by the multi-layer steel cord belt which reduces slip and scrub.

If it can withstand the subzero temperatures of Scandinavia as well as the equatorial temperatures of the African bush, it's certainly good enough for the conditions our Company has to face in Britain.

Frankly, we get our money's worth from the SN55, and that's our main concern.

F. B. Atkins &Sons Limited