munici

Page 78

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

and Pub

Utilities

Water capacity

A water capacity of 2452gal and a foam agent capacity of 415gal combine to give a total foam capacity in ratio of 10 to 1, capable of being dispensed from the monitor nozzle at 10,000 gal /min; from forcer jet curtain sprays constituting a ground sweep forward at 2000 gal /min; from various underbody nozzles to flood the floor beneath the vehicle at 1000 gal/min and two additional hose reels at 1200 .gal /min

giving a total foam capacity of 14,200 gal /min. Should the foam not be in operation there is provision for two water hoses that can operate at a capacity of 500 gal /min each.

Drive for the pump is obtained from a pto behind the torque convertor by shafting to a gearbox and clutch; the power required by the pump is 250 bhp at 80 per cent of the engine speed. The clutch is air operated and the system is so designed that the pump can be engaged /disengaged while the vehicle is in motion.

The mountings of the water storage tank are of a rubber construction which is to be used on the final design and they withstood the most severe shock loads imposed upon them throughout the test, without complaint.

Gear ratio selection up and down is electro-hydraulic, the ratio required being selected with a small lever and the change then being completed automatically by the hydraulic system. Thus unless one is in neutral a gear is always engaged and an increase in revs from idling starts the vehicle moving; there is no neutral between gears. For this reason it was necessary to carry out braking tests in the highest gear (6th).

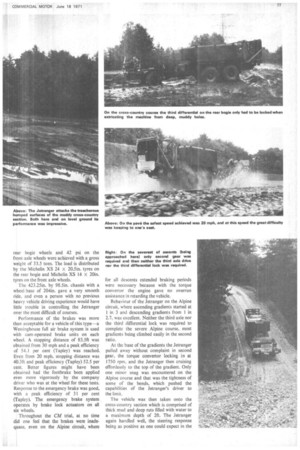

The front axle drive is selected manually using a stout lever located to the left rear of the driving position, the change being made with the vehicle moving slowly forward. Ground loading pressures of 40 psi on the rear bogie wheels and 42 psi on the front axle wheels were achieved with a gross weight of 33.5 tons. The load is distributed by the Michelin XS 24 X 20.5in. tyres on the rear bogie and Michelin XS 14 X 20in. tyres on the front axle wheels.

The 423.25in. by 98.5in. chassis with a wheel base of 204in. gave a very smooth ride, and even a person with no previous heavy vehicle driving experience would have little trouble in controlling the Jetranger over the most difficult of courses.

Performance of the brakes was more than acceptable for a vehicle of this type—a Westinghouse full air brake system is used with cam-operated brake units on each wheel. A stopping distance of 83.5ft was obtained from 30 mph and a peak efficiency of 54.1 per cent (Tapley) was reached. Even from 20 mph, stopping distance was 40.3ft and peak efficiency (Tapley) 52,5 per cent. Better figures might have been obtained had the footbrake been applied even more vigorously by the company driver who was at the wheel for these tests. Response to the emergency brake was good, with a peak efficiency of 31 per cent (Tapley). The emergency brake system operates by brake lock actuators on all six wheels.

Throughout the CM trial, at no time did one feel that the brakes were inadequate, even on the Alpine circuit, where for all descents extended braking periods were necessary because with the torque convertor the engine gave no overrun assistance in retarding the vehicle.

Behaviour of the Jetranger on the Alpine circuit, where ascending gradients started at 1 in 3 and descending gradients from 1 in 2.7, was excellent. Neither the third axle nor the third differential lock was required to complete the severe Alpine course, most gradients being climbed easily in the second ratio.

At the base of the gradients the Jetranger pulled away without complaint in second gear, the torque convertor locking in at 1750 rpm, and the Jetranger then cruising effortlessly to the top of the gradient. Only one minor snag was encountered on the Alpine course and that was the tightness of some of the bends, which pushed the capabilities of the Jetranger's driver to the limit.

The vehicle was then taken onto the cross-country section which is comprised of thick mud and deep ruts filled with water to a maximum depth of 21t. The Jetranger again handled well, the steering response being as positive as one could expect in the

Above: The Twin Disc six-speed constantmash gearbox, showing the drive from the power unit and the air-operated dutch in the background for operating the foam pump.

prevalent conditions. When driven across the tracks instead of along them it was necessary to slow down, the ruts being as wide as the Jetranger's tyres in most instances. The third axle drive was used but it was only necessary to use the third differential lock when extricating ourselves from a deep muddy hole.

Inspection of the rear bogie check-straps at this stage revealed that one had been broken (this type, we were told, will be replaced by stronger ones on the final vehicle).

There can be little doubt that much of the vehicle's success over the difficult ground could not have been accomplished without the Michelin XS tyres. Tyre treads remained exceptionally clean for all the trial, transmitting the maximum of traction in the severest of conditions.

Further trials were then made at Chobham where the 700 bhp engine gave an excellent account of itself, accelerating the 33.5-ton Jetranger to 60 mph in 42 sec, though the gears. It was not possible to reach the maximum speed on the test circuit, a maximum speed of only 64 mph being achieved at 2000 rpm on the test track. Speeds up to and above 70 mph are claimed by Vickers and the Jetranger performance on the CM trial gives us no reason to doubt this figure.

On the lin. concrete setts test road at Chobham, control of the vehicle was maintained up to 40 mph, but on the 2in. concrete setts and the pave speeds of 20 mph were maintained with great difficulty; mainly because without seat stiaps it was impossible to maintain any sort of driving position and still control the vehicle with adequate safety.

Further inspection at this stage showed two more check-straps to be broken, making a total of three; an indication of the severity of the test.

The Vickers engineers being understandably reluctant to allow any further testing on the setts and pave, we adjourned to the steep test hills.

The emergency parking brake held without any apparent difficulty in both directions on the 1 in 3. Restart on the I in 3 was effected easily in first gear with ample power in hand to effect a change to second gear before reaching the top of the gradient. Reverse gear also restarted on the 1 in 3, being a slow climb until the torque convertor locked in, the climb then being completed with ease.

In sum then, the Jetranger proved a most impressive vehicle not only for its sheer performance but also for its controllability in a wide range of varying terrain conditions.