Viaking I go yi it down Yeovil way.

Page 32

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

• •

WE NEED the toughest 'hides for the roughest jobs id I hope we don't have to go reign ; but it might be necestry if UK manufacturers fall )wn on spares," Ken Sperring, ansport manager of S. Morris reovil) Ltd told me when we ere discussing operations ' the company's 42-vehicle pper/mixer fleet and desir)1e vehicle features. The cornmy is big enough to pursue self-determining policy and associated concern owns a harry. But road haulage came afore quarrying ; and obtainig the right vehicles with a Dod spares back-up is :garded as an essential founIlion of viable enterprise. Founder of the company, the le Mr Sidney Morris, started s a horse-and-cart haulier [ter serving in the Royal Navy the First World War. And r 1930 he borrowed £150 to uy a quarry. But although xpansion of the quarry busiess and diversification into le production and supply of Dady-mixed concrete a n d uilding blocks of various ypes has greatly extended the cope of the two companies' ctivities, the haulage side has retained its identity as an allimportant undertaking subject to the vagaries of economic change.

Fortunate

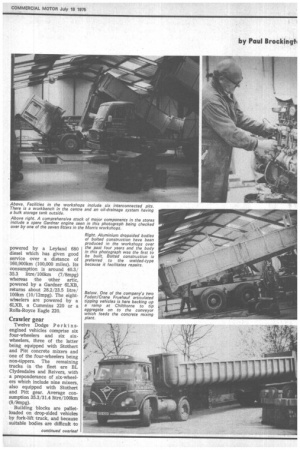

Current 1 y, private-house building provides the main source of revenue, and it is fortunate that a proposal to increase the size of the fleet a year or so ago was turned down. Until recently a substantial proportion of haulage work was 'sub-contracted to other operators. FolloWing a downturn in business of 10 per cent (plus) Morris vehicles now carry all the aggregate, mixed concrete and building blocks produced •by the companies together with aggregate from other quarries and there have been no lay-offs of personnel. Vehicles seldom run empty, sand being frequently carried on the return run after the vehicle has delivered a load of aggregate. Operations are normally limited to a radius of 50 miles.

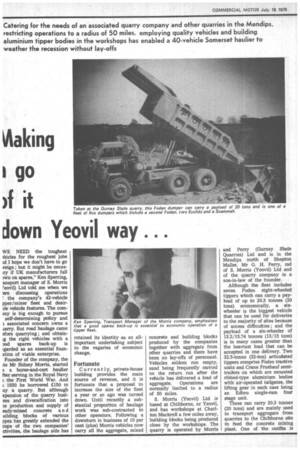

S. Morris (Yeovil) Ltd is based at Chilthorne, nr Yeovil, and has workshops at Charlton Mackrell a few miles away, building blocks being produced close by the workshops. The quarry is operated by Morris and Perry (Gurney Slade Quarries) Ltd and is in the Mendips north of Shepton Mallet. Mr G. H. Perry, rnd of S. Morris (Yeovil) Ltd and of the quarry company is a son-in-law of the founder.

Although the fleet includes seven Foden eight-wheeled tippers which can carry a payload of up to 20.3 tonnes (20 tons) economically, a sixwheeler is the biggest vehicle that can be used for deliveries to the majority of sites because of access difficulties ; and the payload of a six-wheeler of 13.2/15.74 tonnes (13/15 tons) is in many cases greater than the heaviest load that can be accepted in one delivery. Two 32.5-tonne (32-ton) articulated tippers comprise Foden tradtive units and Crane Fruehauf semitrailers on which are mounted ribbed-type aluminium bodies with air-operated tailgates, the lifting gear in each case being an Edbro single-ram four stage unit.

These can carry 20.3 tonnes (20 tons) and are mainly used to transport aggregate from quarries to the Chilthorne site to feed the concrete mixing plant. One of the outfits is powered by a Leyland 680 diesel which has given good service over a distance of 160,900km (100,000 miles). Its consumption is around 40.3/ 35.3 litre/100km (7/8mpg) whereas the other artic, powered by a Gardner 6LXB, returns about 28.2/23.5 litre/ 100km (10/12mpg). The eightwheelers are powered by a 6LXB, a Cummins 220 or a Rolls-Royce Eagle 220.

Crawler gear

Twelve Dodge Perkin sengined vehicles comprise six four-wheelers and six sixwheelers, three of the latter being equipped with &cot:heft and Pitt concrete mixers and one of the four-wheelers being non-tippers. The remaining trucks in the fleet are BL Clydesdales and Reivers, with a preponderance of six-wheelers which include nine mixers, also equipped with Stothert and Pitt gear. Average consumption 35.3/31.4 litre/100km (8/9mpg).

Building blocks are palletloaded on drop-sided vehicles by fork-lift truck, and because suitable bodies are difficult to am and would be costly if y were available, an aluium type has been built in workshops over the past r years. The bodies are of ted construction, which is f erred to welded fabrication :ause it facilitates replacent of damaged panels and :he more convenient method apply in limited production. d building a body is normr a "fill-in" job in that one more of the fitters can get with it in a slack period. total of seven fitters is emyed, and facilities include interconnected pits with a rk bench in the centre and oil-drainage system having bulk storage tank outside. hides are inspected and viced monthly. Mixer operations in particular are very hard on transmissions and Ken emphasises that a crawler gear is essential for tipper and mixer operations if frequent breakdowns and excessive maintenance costs are to be avoided. Even with a crawler gear (most of the vehicles have splitter gearboxes which provide an adequately low starting ratio) a shock-resistant clutch could be a boon. A torque-converter transmission would be unacceptable because it would waste fuel and its first cost would be too high. What about a wet-plate type of clutch as fitted to some American trucks? Ken thinks it might be a worthwhile feature.

Ken pays special tribute to the transmission of the Dodge KT900 and KT1050 which is based on a five-speed gearbox and Eaton two-speed axle. It has given excellent service and vehicle spares are readily available.

While front-ram lifting gears (Edbro) are fitted to Morris tipping vehicles, an Edbro under-body type was tried out on a short-wheelbase vehicle and its use markedly improved its traction capability. Ken may opt for under-body rams for additional applications to swb tippers to gain this 'advantage.

Michelin XZA tyres are generally employed on front axles and XBs at the rear. Remoulded tyres (fitted at •the rear) sometimes have a mileage life very nearly equal to that of a new tyre; and the cost of remoulding of £17 compares with a new price • of £117. Treads are regrooved in the workshops.

Does a 40-vehicle fleet represent an ideal size (in a rural area at any rate) with regard to control of operations and organisation of maintenance ? Such a fleet is not too large for the proverbial advantage of personal-contact cohesion of the staff, to be eroded by the remoteness of management. And as in the case of the Morris fleet it is sufficiently large to justify maintaining a stock of major components for all makes of truck, including engines, clutches, gearboxes, back axles, brake shoes, starters and a lot of other things. And this is of special importance in times of doubtful spares availability. ,