;edford TMs swing into phase two with nine new models

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

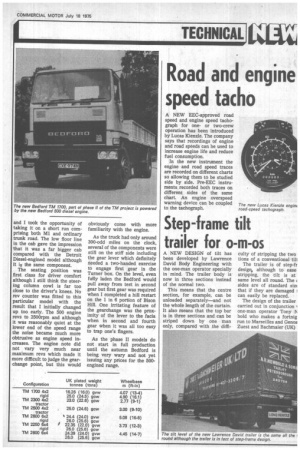

Graham Montgomerie S SECOND production se of Bedford TM models begin in the autumn. Be3e of the production diffiies inherent with a new lel range, Bedford divided rm introduction into separphases with the first phase Detroit Diesel engined :•.ks being unveiled at Earls irt last year.

he second phase of TM protion, which will start in the urnn, comprises nine basic iants for the UK market h a further four models to built for export markets. power unit for these dels will be the new Bedd 500 engine which superRs the existing 466 unit. Che nine models comprise 'en rigids and two tractive ts with gross design weights iging from 17 to 25 tonnes to 24.5 tons). Two of the ir-wheel rigids were designto be particularly suitable drawbar operation at a )ss weight of 25 tonnes. The 1 range of phase II is shown the accompanying panel.

Oeuin

The new 500 engine shares same basic design concept the 466 which it replaces, t Bedford insists that it is a mpletely new engine. From cubic capacity of 8.2 litres DOcuin) the engine develops 2kW (151bhp) at 2,500rpm th the maximum torque of 4Nm (3771bft) occurring at Orpm.

Great attention has obviously ien paid to the problem of use emission with the addiDin of sound-deadening marials to the sump, side covers id rocker cover. A lead minate is used on the rocker )ver while panels of soundmdened-steel are spot-welded the inside of the sump.

The cylinder head gasket is ade from laminated steel and uses a double fire ring nploying a primary and secndary seal. The coolant flow a the 500 engine is from end ) end using two water transfer orts at the rear to transfer le water from block to head. hese ports are outside the asket area which means this component is required to provide a gas seal only.

Chrome

Although the 500 engine shares many common design features with the superseded 466, the ring pack is completely different. Three rings are used, all chrome plated, with the wedge-type top ring being located in a cast iron insert in the aluminium piston.

The 500 engine is also to be used in existing Bedford models where the 466 is currently fitted. The version for the TK truck is rated at 94kW (126bhp) while the 10 and 11metre bus and coach chassis (designated YLQ and YMT) will be powered by 105kW (140bhp) and 119kW (160bhp) variants respectively.

All the phase II models are equipped with the regularwidth D cab already to be seen on the Detroit Diesel models. Because of the difference in engine height the 500 cab is more like a " walk-through " model with a double passenger seat being an available option because of this.

Axle

The Turner TS-400 fivespeed synchromesh overdrive gearbox is the standard transmission for the 4 x 2 rigid models with option of the Eaton 542 six-speed unit. The latter is standard for the 6 x 2 and tractive units. The clutch is a single-dry-plate design of 381mm (15in) diameter.

The rear axle specification is rather more complicated. The 4 x 2 trucks use Bedford's own 11 tonne (10.8 ton) spiral-bevel axle with Eaton 18100 or 18300 axles being fitted to the 23 tonne (22.6 ton gcw and 25 tonne (24.6 ton) gcw tractors respectively. The 183000 double-reduction spiral-bevel is used on the 6 x 2 with the 6 x 4 employing the 38DS heavy-duty tandem axle, again from Eaton.

The front springs are twoleaf tapered semi-elliptic with conventional multi-leaf components being fitted at the rear.

A fully laden 16-tonner was on hand at the Bedford engineering block for brief appraisal and I took the opportunity of taking it on a short run comprising both Ml and ordinary trunk road. The low floor line in the cab gave the impression that it was a far bigger cab compared with the Detroit Diesel-engined model although it is the same component.

The seating position was first class for driver comfort although I still think the steering column cowl is far too close to the driver's knees. No rev counter was fitted to this particular model with the result that I initially changed up too early. The 500 engine revs to 2500rpm and although it was reasonably quiet at the lower end of the speed range the noise became much more obtrusive as engine speed increases. The engine note did not vary very much near maximum revs which made it more difficult to judge the gearchange point, but this would obviously come with more familiarity with the engine.

As the truck had only around 300-odd miles on the clock, several of the components were still on the stiff side including the gear lever which definitely needed a two-handed exercise to engage first gear in the Turner box. On the level, even fully laden the Bedford would pull away from test in second gear but first gear was required when I completed a hill restart on the 1 in 6 portion of Bison Hill. One irritating feature of the gearchange was the proximity of the lever to the facia when in second and fourth gear when it was all too easy to trap one's fingers.

As the phase II models do not start in full production until the autumn Bedford is being very wary and not yet issuing any prices for the 500engined range.