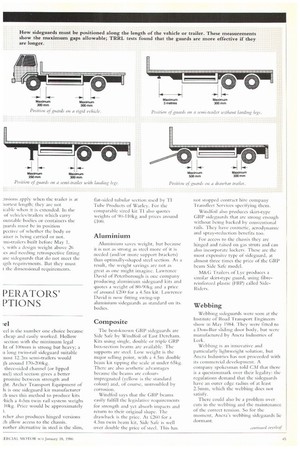

PERATORS' PTIONS

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

:ed is the number one choice because cheap and easily worked. Hollow section with the minimum legal ht of lOomm is strong but heavy; a a long twin-rail sidcguard suitable most 12.2in semi-trailers would gh around 170-200kg.

three-sided channel (or lipped mel) steel section gives a better .promise between strength and ;ht. Archer Transport Equipment of Is is one sidcguard kit manufacturer ch uses this method to produce kits rhich a 4-5m twin rail system weighs 10kg. Price would be approximately

rcher also produces hinged versions ch allow access to the chassis.

nother alternative in steel is the slim, flat-sided tubular section used by TI Tube Products of Warley. For the comparable sized kit TI also quotes weights of 90-110kg and prices around 100.

Aluminium

Aluminium saves weight, but because it is not as strong as steel more of it is needed (and/or more support brackets) than optimally-shaped steel section. As a result, the weight savings are not as great as one might imagine. Lawrence David of Peterborough is one company producing aluminium sideguard kits and quotes a weight of 80-90kg and a price of around i:200 for a 4.5m kit. Lawrence David is now fitting swing-up aluminium sideguards as standard on its bodies.

Composite

The best-known GRP sideguards are Side Safe by Windfoil of East Dereham. Kits using single, double or triple GRP box-section beams are available. The supports are steel. Low weight is the major selling point, with a 4.5m double beam kit tipping the scale at under 65kg. There arc also aesthetic advantages because the beams are colourimpregnated (yellow is the standard colour) and, of course, untroubled by corrosion.

Windfoil says that the GRP beams easily ti.ilfiH the legislative requirements for strength and yet absorb impacts and return to their original shape. The drawback is the price. At $260 for a 4.5m twin beam kit, Side Safe is well over double the price of steel. This has not stopped contract hire company Transfleet Services specifying them.

Windfoil also produces skirt-type GRP sideguards that are strong enough without being hacked by conventional rails. They have cosmetic, aerodynamic and spray-reduction benefits too.

For access to the chassis they are hinged and raised on gas struts and can also incorporate lockers. These are the most expensive type of sideguard, at almost three times the price of the GRP beam Side Safe model.

M&G Trailers of Lye produces a similar skirt-type guard, using fibrereinforced plastic (FRP) called SideRiders.

Webbing

Webbing sideguards were seen at the Institute of Road Transport Engineers show in May 1984. They were fitted to a Don-Bur sliding door body, hut were manufactured by Ancra Industries of Leek.

Webbing is an innovative ,ind particularly lightweight solution, but Ancra Industries has not proceeded with its commercial development. A company spokesman told CM that there is a questionmark over their legality: the regulations demand that the sideguards have an outer edge radius of at least 2.5mm, which the webbing does not satisfy.

There could also be a problem over cuts in the webbing and the maintenance of the correct tension. So for the moment, Ancra's webbing sideguards lie dormant.