For DRIVERS, MECHANICS & FOREMEN.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on thiS page, and an EXTRA -FIVE SHILLINGS to the sender of the one which we select as being the best each week. All notes are edited before being published. Mention your employer's name, in conddence, as evidence of good faith. -Address, D„ it. nd F., "The Commercial Motor," 7-15; Rosebery Avenue, ,Lonclon, E.G. 1,

Lamps Alight.

On Saturday, January 22nd, light your lamps at 459 in London, 4.65 in Edinburgh, 4:51 in Newcastle, 5.3 in Liverpool, 5.7 in Birmingham, 5.9 in Bristol, and 5.16 in Dublin.

Dismantling Inaccessible Connecting Rods.

The sender of the follouzing communication has been awarded the extra, payment of 5s. this week.

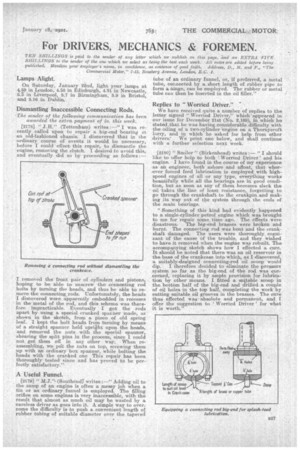

[2178] " J.H." (Tottenhaan) writes :—" I was recently, called upon to repair a big-end bearing in an old-fashioned chassis. I discovered that in the ordinary course of events it would be necessary, before I could effect this repair, to dismantle the engine, removing the clutch. I desired to avoid this, and eventually did so by proceeding as follows :— removed the front pair of -cylinders. and pistons, hoping to be able to unscrew the connecting rod bolts by turning the heads, and thus be able to re, move the connecting rods. Unfartunatialy, the heads I discovered were apparently embedded in recesses in. the metal of the rod, and this scheme was therefore impracticable. Eventually I got the rods apart by using a special cranked spanner made, as' shown in the sketch, from a piece, of old spring leaf. I kept the bolt heads from turning by means. of a straight spanner held U.pribt upon the heads, and regnoved the nuts with the special spanner, shearing the split pins in the process, since I could not get them off in any other way. When reassembling, we pia the nuts on top, screwing them up with an ordinary box spanner, while bolting the. heads with the cranked one This repair has been thoroughly tested since and has proved to be per-' feetly satisfactory."

A Useful Funnel.

[2179] "ILL"(Southend). writes :—" Adding oil to the sump of an engine is often a messy job when a tin or 'an ordinary funnel is employed. The filling orifice on some engines is very inaccessible, with the result that almost as much oil may be wasted by a careless driver as goes into it.' A simple way to over-come the difficulty is to push a convenient length of rubber tubing of suitable diameter over the tapered tube of an ordinary funnel, or, if preferred, a metal tube, connected by a. short length of rubber pipe to form a ninge, can be employed. The rubber or metal tube can then be inserted in the oil filler."

Replies to "Worried Driver."

We have received quite a number of replies to the letter signed "Worried Driver," which'appearecl in our issue for December 21st (No. 2,169), in which he stated,that he was haxing.consiclerable difficulty with the oiling of a two-cylinder 'engine on a Tharnycroft lorry, and in which he asked for help from other ,drivers: We print one below, and shall continue with a farther selection next week.

[2180] " Smiler" (Birkenhead) writes :— " I should like to offer help to both '.Worried Driver' and his engine. I have found in the course of my experience as an engineer, both ashore and afloat, that wherever forced feed lubrication is emPloyed. with highspeed engines of all or any type, everything works beautifully while all -the bearings are in good condition, but as Soon as any of them becomes slack the --oil takes the -line of' least resistance, forgetting to go through the crankshaft to the crankpin.and making its way out of the system through the ends of the main bearings.

"Something of this kind, had evidently _happened to a single-cylinder petrol engine which was brought to. me for 'repair some time ago. The effects were disastrous. The big-end brasseswere broken and burnt. The connecting rod was bent and the crank-shaft damaged. The users were thoraughly_ cognizant of the cause or the trouble, and they wished to have it removed when the engine was rebuilt. The accompanying sketch shows how I effected a cure. It should be noted that there was an oil reservoir in the base of the crankcase into which, as I discovered, a suitably-designed connecting-rod oil scoop -would dip. I therefore decided to -eliminate the pressure system. so far as the big-end of the rod was conCerned, replacing it by ample provision for lubrication by other means. I fitted a suitable scoop in the -bottom half of the big-end and -drilled., a couple of oil holes in the top half, completing the work by cutting suitable, oil grooves in the brasses. The cure thus effected was absolute and permanent, and I offer the suggestion to Worried Driver for what it is worth.'