Delivering Christmas

Page 66

Page 67

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

Christmas doesn't just happen. All the toys, trimmings, tipples and turkeys have to come from somewhere. We find out how the road transport industry does its bit for the festive season...

Words: Roanna Avison

Christmas Tree

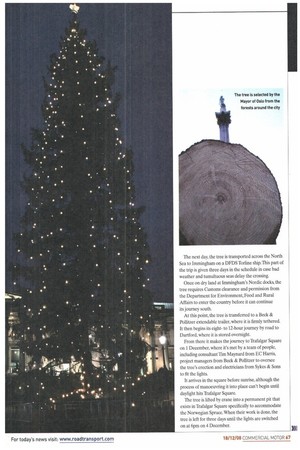

As a sign of gratitude to the British nation that gave Norway's leaders refuge from German troops for five years during the Second World War, a Norwegian spruce is given to the UK each Christmas and it is erected in Trafalgar Square.

The tree is selected by the Mayor of Oslo from the forests around the city. and is usually about 21.5m high,4m wide and with a trunk diameter of 500-700mm. Of course, once selected, this tree has to be transported from Oslo to London...

This task is overseen by project managers EC Harris, which has a contract with the Greater London Authority to manage the tree's delivery every year, while Beck & Pollitzer is responsible for haulage and erection of the tree. The tree is relatively light as abnormal loads go, but it is delicate, which translates as a special challenge for the team.

The tree is cut down on 27 November, having been secured to a mobile crane with a harness. It is then manoeuvred on to a truck with the help of a team of lumberjacks, before starting its policeescorted five-hour trek to the port of Brevik.

To protect it from the elements and any other damage that might befall it during transit, the tree is wrapped in tarpaulin.

The transport in Norway is organised by the British embassy in Oslo. The next day, the tree is transported across the North Sea to Immingham on a DFDS Torline ship. This part of the trip is given three days in the schedule in case bad weather and tumultuous seas delay the crossing. Once on dry land at Immingham's Nordic docks, the tree requires Customs clearance and permission from the Department for Environment, Food and Rural Affairs to enter the country before it can continue its journey south.

At this point, the tree is transferred to a Beck & Pollitzer extendable trailer, where it is firmly tethered. It then begins its eightto 12-hour journey by road to Dartford, where it is stored overnight.

From there it makes the journey to Trafalgar Square on 1 December, where it's met by a team of people, including consultant Tun Maynard from EC Harris, project managers from Beck & Pollitzer to oversee the tree's erection and electricians from Sykes & Sons to fit the lights.

It arrives in the square before sunrise, although the process of manoeuvring it into place can't begin until daylight hits Trafalgar Square.

The tree is lifted by crane into a permanent pit that exists in Trafalgar Square specifically to accommodate the Norwegian Spruce. When their work is done, the tree is left for three days until the lights are switched on at 6pm on 4 December.

Christmas drink

Similar to a number of other breweries, Shepherd Neame creates ales that are designed to capture the Christmas spirit. In fact, the Faversham, Kent-based company has two — the Christmas Ale and the Winter Hop Ale. Andy Miller, distribution general manager at Shepherd Neame, tells CM that during the summer, the company will work out the quantity of these beers they will need to brew based on previous year's sales figures and sales predictions for this year.

Production will take about 12 weeks, and the brewery will expect to have it all ready to be distributed in its warehouse by early October. "This is because we export some of it — that needs to happen quite early," Miller says. Then, at the end of October and the beginning of November, its Christmas Ale will be shipped to third-party warehouses and to local pubs and clubs. Shepherd Neame operates its own fleet of drays that it uses to make deliveries to its managed sites such as clubs, pubs and British Legions. These cover an area including Essex. London, Hampshire, Sussex, Surrey and Kent.

The brewery has a fleet of Euro-5 Volvo tractor units which it bought to comply with the London LEZ.

Miller says approximately 55% of the UK delivery of Christmas Ale is moved by Shepherd Neame's own fleet, and for sale in licensed premises.

"The trucks will go out daily, and most areas will receive two deliveries a week. However, the closer we are to home in Kent, the more likely we are to do daily deliveries."

The remaining 45% of UK stock is collected from Shepherd Neame's Faversham warehouse by customers "They will contact our customer service department and arrange a time to come to collect their consignment.

"It is unlikely that the customer will just be taking the Christmas Ale, and so the load will probably be made up of all our regular ales as well as the special Christmas one," Miller says.

For some customers, Shepherd Neame will deliver into RDCs outside its traditional delivery area.

"As we get more national brands, this may become a bigger part of our transport operations." The Winter Hop Ale is handled slightly differently because the majority of the volume produced goes to the supermarket chain Asda. It is a relatively new beer to the Shepherd Neame family, and so the volumes are much lower than the Christmas Ale.

Shepherd Neame is responsible for taking the consignments to Asda's RDC in Lutterworth, Asda then organises transport of the Winter Hop Ale to its stores.

Miller says Shepherd Neame uses local hauliers to do this work, but it does put the job out to tender each year.

"Who we use depends on who gives us a competitive quote in line with local market rates." he adds.