UPLAND TIMBER HAULAGE

Page 64

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

east of

tinpuinD

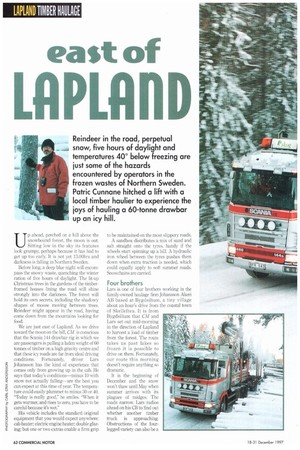

Reindeer in the road, perpetual snow, five hours of daylight and temperatures 40° below freezing are just some of the hazards encountered by operators in the frozen wastes of Northern Sweden. Patric Cunnane hitched a lift with a local timber haulier to experience the joys of hauling a 60-tonne drawbar up an icy hill.

Up ahead, perched on a hill above the snowbound forest, the moon is out. Sitting low in the sky its features look grumpy, perhaps because it has had to get up too early. It is not yet 13.00hrs and darkness is falling in Northern Sweden.

Before long, a deep blue night will encompass the snowy waste, quenching the winter ration of five hours of daylight. The lit-up Christmas trees in the gardens of the timberframed houses lining the road will shine strongly into the darkness. The forest will hold its own secrets, including the shadowy shapes of moose moving between trees. Reindeer might appear in the road, having come down from the mountains looking for food.

We are just east of Lapland. As we drive toward the moon on the hill, CM is conscious that the Scania 144 drawbar rig in which we are passengers is pulling a laden weight of 60 tonnes of timber on a high gravity centre and that these icy roads are far from ideal driving conditions. Fortunately, driver Lars johansson has the kind of experience that comes only from growing up in the cab. He says that today's conditions—minus 10 with snow not actually falling—are the best you can expect at this time of year. The temperature could easily plummet to minus 30 or 40. "Today is really good," he smiles. "When it gets warmer, and rises to zero, you have to be careful because it's wet."

His vehicle includes the standard original equipment that you would expect anywhere: cab heater; electric engine heater; double glazing; but one or two extras enable a firm grip to be maintained on the most slippery roads.

A sandbox distributes a mix of sand and salt straight onto the tyres, handy if the wheels start spinning up a hill. A hydraulic iron wheel between the tyres pushes them down when extra traction is needed, which could equally apply to soft summer roads. Snowchains are carried.

Four brothers'

Lars is one of four brothers working in the family-owned haulage firm Johansson Akeri AB based at Bygclsilium, a tiny village about an hour's drive from the coastal town of Skelleftea. It is from Bygdsilium that CM and Lars set out mid-morning in the direction of Lapland to harvest a load of timber from the forest. The route takes us past lakes so frozen it is possible to drive on them. Fortunately, our route this morning doesn't require anything so dramatic.

It is the beginning of December and the snow won't thaw until May when summer arrives with its plagues of midges. The roads narrow. Lars radios ahead on his CB to find out whether another timber truck is approaching. Obstructions of the fourlegged variety can also be a hazard. Reindeer give other road users no special consideration, says Lars, since they have been using these feeding grounds for hundreds of years. "They look at the trucks and wonder why you are here!" He has avoided hitting reindeer but not every driver does: "You see lots of dead ones in the ditch."

Nasiy infections

Severe cold—down to minus 40°—leads to problems with the Jonserrad timber crane mounted on his drawbar unit. "It can get very sluggish. You have to warm up the oil before loading. Otherwise parts can wear out much faster. And because it's high pressure the pipes can explode, showering you in oil." Such accidents happen regularly and oil under the skin can cause nasty infections. At least the oil is now environmentally-friendly, he adds, and less likely to pollute the water table.

At one point we need to make a U-turn. Fortunately, the truck has yet to be loaded so Lars gingerly reverses into a side road and cautiously swings the 24m body to face the opposite direction. He says that he avoids looking in the passenger mirror because seeing the ditch makes him nervous. The snow drifts on either side can be metres deep: "You can hear it when you are in the snow!" The turn safely executed, he relaxes. "It takes years to learn where you can turn. You have to work out the possibilities. I've never tipped a trailer but this trailer has been tipped on a weak road: it's very easy to do in these conditions."

And so we reach the pick-up point. Piles of cut timber line the roadside. Lars jumps out of the cab and climbs aboard the crane. Nimbly and deftly the grab swings clutches of timber onto the trailer. Lars works with enviable speed and accuracy. When full, the rear drawbar section slides back to allow the third and final section to be loaded. In less than 25 minOp. 41 utes the unit is fully laden to its 60-tonne capacity.

The difference is noticeable on the return journey. There is a distinct "pull" on the hills. "Now you could do with 530hp," laughs Lars. The 144 has 460hp but, as he explains, the extra cost of fuel for a bigger engine would outweigh the advantages. This may be so but it might avoid some of the hairier moments. On a hill climb last year his truck started to go backwards: "I put the chains on but sometimes you have to take the whole load off otherwise you are in the ditch."

Last month he was forced to drive off the road to avoid another timber truck coming towards him. "Neither of us could stop." Considering these aggravations has he ever wanted to do anything else? "I get fed up sometimes but I would not .want to be in another industry. Transport is very free, you can see other places. Perhaps in the winter when it's raining you want to be someplace else, when you have to wait for the sand truck."

Coffee and pretzels

Earlier that morning CM enjoyed coffee and pretzels with the whole Johansson clan, Henry and his sons Lars, Roger, Ove and Ake: a real family unit like haulage firms the world over. Roger's wife Anita and Ove's wife Britt look after the office. Roger is managing director, Ove is responsible for the vehicles, Lars drives and Ake shares driving and maintenance duties Henry comes in on Fridays and Saturdays to look after the tyres. He is semi-retired or as he puts it, "They can't afford me the rest of the week." Employed drivers complete the team.

The business was founded by Henry's father Gunnar in 1923, running Model T Ford taxis. By 1932 Gunnar found that cabbing wasn't paying its way so, in 1932, he moved into trucks. Young henry joined him in 1937 at the tender age of 12 and the business expanded to include milk collection and timber. Today the business is exclusively timber, working from a site next door to its main customer, Martinsons timber mill. The fleet has been Scania since 1985 when, as a two-truck business, it took over another firm running Scanias.

Roger is pleased with the current fleet's performance: "We are very satisfied with the V8 engine, we have few repairs and low fuel consumption." It collects timber for Martinsons from forests within 300km of Bygdsilijum and delivers finished product to the port for export. The biggest export customer is the UK, followed by Italy. About half the timber is used for building and furniture, the rest goes to paper mills and fuel producers. Does the company feel vulnerable being so dependent on one customer? Roger admits that there could be dangers but says there's another side to that coin: "It's a big plant, very stable."

He has a point. The work is there, Two vehicles have been added to the fleet this year. Whether in winter darkness or interminable summer daylight, Johansson works a fourday, double-manned shift of 20 hours and one Friday shift of 10 hours. Drivers work no more than 40 hours a week, music to the ears of the average 60-hours-plus a week British driver. Naturally, the family keeps different hours: "This is what I do in my spare time as well," declares Roger, drawing on his pipe.

CM remarks that one major difference is Sweden's limit of 60 tonnes laden weight compared to Britain's rather puny-by-comparison 38 tonnes, Doesn't such high tonnage damage the roads? Roger agrees that it does but says, "If it was not 60 tonnes it would be two trucks bringing the same load." He adds that each truck pays up to 250,000 Swedish kroner (about £20,000) a year in tax including fuel tax and a road tax of 30,000 kroner (about £2,400) per year per vehicle. It sounds like a litany of familiar problems More coffee is poured and the brothers recall growing up with their father (who sits quietly basking in the warmth of their praise) and how he passed on his enthusiasm to them at an early age. "We have had a good teacher since we were small," says Roger. "We were learning to drive since nine or 10 years old so we grew up in the cab. When we started to drive we were so small we could not see the clutch." Was that strictly legal? "No, but the police stations are far away!"

FACTFILE: JOHANSSON AKER! AB BASED: Bygdsilium, near Skelleftea, Sweden. FOUNDED: 1923 by Gunnar Johansson as a taxi firm. Moved into trucks in 1932. CONV Roger Johansson, managing director. NIL Seven Scaniastwo 144s; three Streamlines; two Toplines. All Vit powered. Most recent purchase: 144, February 1997, 143, August 1997. SPECIALTY CONTRACT: Timber haulage. TURNOVER: 10m Sw Kroner (C800,000).