HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

461.---Providing Better Lubrication for the Radius Rod Bushes of the Hanford.

On the E.F. type Hallford the only lubrication for the cast-iron radius rod bushes is that which finds its way between the oil-retaining ring and the radius rod, and in some cases this has proved insufficient. To enable better lubrication to be effected, in certain instances two grease cups have been fitted on the underside of each radius rod. These should be inserted at an angle, one near the brake quadrant and the other on the opposite side.

it will be found necessary to use a socket and nipple in order to bring the grease cup far enough awayfrom the rod to permit screwing the cups into position. The bush in each rod should be grooved to allow the grease to be forced round the axle. It will be found that this prolongs the life of the bushes to a considerable extent and doesaway with brake chatter.

Another place where grease cup--; are an advantage on this type of lorry is on the steering column, one to supply the brass bush just wider the steering wheel, and the other the bush at thebottom of the column where it bolts on to the steering box.

It is necessary to point out that it is quite useless fitting these cups unless they are kept filled.

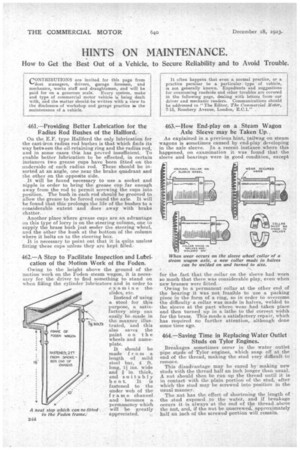

462.—A Step to Facilitate Inspection and Lubrication of the Motion Work of the Foden.

Owing to the height above the ground of the motion work on the Feder' steam wagon, it is necessary for the driver to find something tostand on when fil4ing the cylinder lubricators and in order to examine the slides, etc.

Instead of using a stool for this purpose, a. satisfactory step can easily be -made in the manner illustrated, and this also saves the paint on the wheels and nameplate.

It should be made from a length of mild steel bar, 4 ft. long, 1 ins, wide and in. thick, and suitably bent. It is fastened to the under web of the frame channel, and becomes a permanency which will be greatly appreciated. 463.—How End-play on a Steam Wagon Axle Sleeve may be Taken Up, As explained in a previous hint, tailwag on steam wagons is sometimes caused by end-play developing in the axle sleeve. In a recent instance where this happened, on examination it IN as found that the sleeve and bearings were in good condition, except for the fact that the collar on the sleeve had worn so much that there was considerable play, even when new brasses were fitted.

Owing to a permanent collar at the other end of the bearing it was not feasible to use a packing piece in the form of a ring, so in order to overcome the difficulty a collar was made in halves, welded to the sleeve at the part where wear had talen place and then turned up in a lathe to correct width for the brass. This made a satisfactory repair, which has required no further attention, although done some time ago.

464.—Saving Time in Replacing Water Outlet Studs on Tylor Engines.

Breakages sometimes occur in tho water outlet pipe studs of Tylor engines, which snap off at the end of the thread, making the stud very difficult to remove.

This disadvantage may be cured by making new studs with the thread half an inch longer than usual. A nut should then be run up the thread until it is in contact with the plain portion of the stud, after which the stud may be screwed into position in the usual manner.

The nut has the effect of shortening the length of the stud exposed to the water, and if breakage occurs it is always at the end of the thread, above the nut, and, if the nut be unscrewed, approximately half an inch of -the screwed portion will remain.