Production rationalization gets under way

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

The first engine of the new Mercedes-Benz 400 series was announced at the Frankfurt show in 1969. That engine was a V-10, but we have learnt since that a whole family consisting of V-6, V-8, V-10 and V-12 configurations will be produced and that these units have been designed to accept turbocharging at a later date.

Also based on the same bore and stroke measurements are straight 4-, 5and 6-cylinder versions; the 5and 6-cylinder types are also being developed in a horizontal form suitable for buses.

Bore and stroke dimensions of all these engines are common at 125mm and 130mm except for the horizontal engines in which the stroke is 150mm. As a rough guide, engine horse power output may be taken as 32 bhp per cylinder in normally aspirated form and 40 bhp per cylinder in turbocharged form. The 400 series of engines, then, covers the complete range of outputs from 130 bhp to 480 bhp.

The 400 series engines are built in a new plant at Mannheim which started production on January 1 this year. Engine blocks and heads are cast at an adjoining

foundry which was opened in 1965. Production of the existing 300 series engine will continue for some years but will be phased out gradually as later vehicles are designed to take the new engines. Production of the 400 series engine is highly automated and capacity of the existing plant is 6000 units per month.

Gear cutting is concentrated at another Mercedes-Benz plant in Gaggenau and here a new line has been laid down for the production of the new hub reduction axle announced at the Geneva show earlier this year. Although basically the same, two axles are made: one is a 10/12 ton design with a 230mm (9in.) crown wheel; the 13-ton design has a 300mrn (11lin.) crown wheel. Present production capacity is 6000 units per month but this could be raised to 10,000 units per month if necessary.

All trucks over 6-ton gvw are assembled at %firth. This plant has two production Lines, each capable of building any truck in the range, and at present the two lines are together producing 280 trucks per day. The cab line is more akin to that of a car plant and includes very modern phosphating,

primer dipping and finish painting facilities All cabs are finish-painted in one of fiv( standard colours, or 60 optional colours Some 35 per cent of all cabs built are of th( bonneted type, underlining their popularit3 with tipper and mixer operators and ir overseas markets.

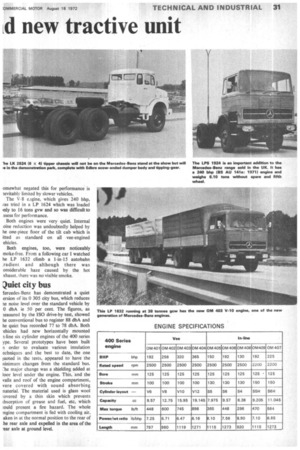

On the road I• tried the V-10 engine in an LP 1632 loaded to 38 tons gcw. Time allowed only a short run and this factor, combined with heavy holiday traffic, defeated any meaningful test. Over a 70 miles route which included hilly sections of autobahn and some town running, the vehicle achieved only 5.2 mpg at an average speed of 30 mph. This is a considerably poorer figure than that achieved with this same vehicle over a longer test last year (CM April 23 1971). Then it achieved 6.2 mpg at an average speed of 38 mph over a 348 mile route. The V-10 engine gives the LP 1632 just over 8.5 bhp per ton and the performance is very good as a result, but the strict German law requiring heavy vehicles to stay in the nearside lane on hills omewhat negated this for performance is -tevitably limited by slower vehicles.

The V-8 e.Igine, which gives 240 bhp, as tried in a LP 1624 which was loaded irily to 16 tons gvw and so was difficult to ssess for performance.

Both engines were very quiet. Internal oise reduction was undoubtedly helped by he one-piece floor of the tilt cab which is itted as standard on all vee-engined ehicles.

Both engines, too, were noticeably moke-free. From a following car I watched he LP 1632 climb a 1-in-15 autobahn ,radient and although there was onsiderable haze caused by the hot xhaust. there was no visible smoke.

Niet city bus

lercedes-Benz has demonstrated a quiet ersion of its 0 305 city bus, which reduces rie noise level over the standard vehicle by 0 dbA ie 50 per cent. The figures, as -teasured by the ISO drive-by test, showed he conventional bus to register 88 dbA and he quiet bus recorded 77 to 78 dbA. Both .ehicles had new horizontally mounted six cylinder engines of the 400 series ype. Several prototypes have been built 3 order to evaluate various insulation echniques and the best to date, the one Rioted in the tests, appeared to have the ninimum changes from the standard bus. he major change was a shielding added at loor level under the engine. This, and the valls and roof of the engine compartment, vere covered with sound absorbing naterial. The material used is glass wool :overed by a thin skin which prevents tbsorption of grease and fuel, etc, which :mild present a fire hazard. The whole :ngine compartment is fed with cooling air, aken in at the normal position to the rear of he rear axle and expelled in the area of the .ear axle at ground level.