Road Trai

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

)rtis

Part in E

.ing

Europe's : Test Steel V\

Up to 169 Vehicles Used in £60,000,000 Project to Raise Steel Strip and Plate Output by 20,000 Tons a Week

By P. A. C. Brockington, A M.I.Mech.E.

STATISTICAL superlatives are inescapable in describing any part of the £60,000,000 project of the Steel Co. of Wales for implementing the country's steel strip and plate production by 20,000 tons a week. When full output is reached next year, it is possible that the restrictions on strip supplies will be removed, and the motor industry should be the first to benefit. It is thprefore appropriate that road transport should play an essential part in the ground preparation and constructional work on the reclaimed site for the mills and ancillary installations at the Abbey works on Margam Moors, near Port Talbot, Glamorganshire, the key plant of the project

The major transport job on the site is in connection with the melting shop and continuous-strip hot mill (which will be nearly a mile long), and with the adjoining mould-preparation shop. At the peak period between November, 1948, and the summer of 1949, the civil-engineering contractor, George Wimpey and Co., Ltd., 23, Hammersmith Grove, London, W.6 employed 169 vehicles, including 70 hired machines, which covered an average of 30 miles a day over extremely marshy and badly ditched ground.

Some of the sand fill to provide a base for the foundations was pumped from the nearby dunes after mixing with water, but the greater part, approximately 1,800,000 cubic yds, was conveyed in tippers from the dunes, a distance of 1,300 yds. In addition, 1,140,000 cubic yds. of slag were hauled 2,000 yds., after blasting from a solid heap formed from the waste of the Maream blast furnaces. The current production of slag from these works was tipped into a lagoon and reduced in size to pieces of 6-12 ins, by spraying with jets of water. which caused rapid shrinkage, and consequent fracture. without further blasting. The slag was then dug out and reloaded for transfer to the site. Excavations necessitated the removalof 667,000 cubic yds. of material, about half of which was in hard ground, and this was spread on the dunes to stabilize the sand.

The original level of the moors was raised by some 10 ft. and the foundations were piled to a depth of 20-50 ft. with over 26,000 60-ton piles. Haulage of the concrete involved a particularly difficult transport job More than 200,000 cubic yds. were carried an averag. of 440 yds., and the concrete mixers had to be supplied with 75,000 cubic yds. of sand from the site dunes.

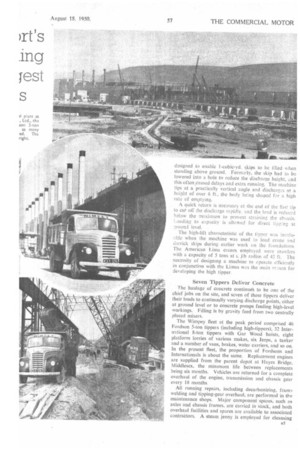

A high-tipping 2-cubic-yd. concrete lorry—familiarly known as a "doodlebug "—was specially developed by Wimpeys for the Abbey works contract. The body is mounted on a Fordson Thames chassis and was designed to enable 1-cubic-yd. skips to be tilled• when standing above ground. Formerly, the skip had to be lowered into a hole to reduce the discharge height, and this often paused delays and extra running. The machine tips at a practically vertical angle and discharges at a height of over 6 ft., the body b&ng shaped for a high rate of emptying.

A quick return is necessary at the end of the first tip to cut off the discharge rapidly, and the load is reduced below the maximum to prevent straining the thiSS:S. ;,Oadii13 to capacity is allowed for direct tippncf at round The high-lift characteristic of the tipper was invniiiztble when the machine was used to load crane and derrick skips during earlier work on the foundations, The American Lima cranes employed were crawlers with a capacity of 5 tons at a jib radius of 45 ft. The necessity of designing a machine to operate efficiently in conjunction with the Limas was the main reason for developing the high tipper.

Seven Tippers Deliver Concrete The haulage of concrete continues to be one of the chief jobs on the site, and seven of these tippers deliver their loads to continually varying discharge points, either at ground level or to concrete pumps feeding high-level workings. Filling is by gravity feed from two centrally placed mixers.

The Wimpey fleet at the peak period comprised 46 Fordson 5-ton tippers (including high-tippers), 32 International 8-ton tippers with Gar Wood hoists, eight platform lorries of various makes, six Jeeps, a tanker and a number of vans, brakes, water carriers, and so on. In the present fleet, the proportion of Fordsoris and Internationals is about the same. Replacement engines are supplied from the parent depot at Hayes Bridge, Middlesex, the minimum life between replacements being six months. Vehicles are returned for a complete overhaul of the engine, transmission and chassis gear every 18 months.

All running repairs, including decarbonizing, frame welding and tipping-gear overhaul,are performed in the maintenance shops. Major component .spares, such as axles and chassis frames, are carried in stock, and both overhaul facilities and spares are available to associated contraCtors. A steam jenny is employed for cleansing

chassis and all other parts before repair, and has come to be regarded as an essential item of garage equipment.

A Bedford fuel tanker has been in continuous use 24 hours a day for more than two years, and during the peak period was supplying 30 excavators, 19 bulldozers and 12 Euclid dumpers with fuel and lubricating oil, in addition to the large number of compressors, mixers and other plants on the site. Two tanks, each with a capacity of 400 gallons, carry the oil fuel and petrol, and three 40-gallon lubricating-oil drums are mounted at the back of the vehicle. Fordson water tankers, with a capacity of 1,000 gallons, are used for concretemixing and road spraying.

Arduous Conditions

Some indication of the arduous operating conditions may be gained from the replacement figures for tyres and springs. Since the start of the ground-preparation work in April, 1947, 3,000 new springs have been fitted (including individual blade repairs) and over 2,000 new tyres.

Redex is used as a petrol additive throughout the life of an engine. All engines are checked regularlywith the Redex performance tester. Lubricating oil is changed every week and, after processing in a Stream Line filter, the oil is re-issued for topping-up. The Stream-Line plant is a stationary installation, but plans have been prepared to mount the various components on the lorries to provide self-contained units.

The fitters are employed on a rota system for night repairs and week-end inspections. From the start of operations, about 75 per cent. of the drivers and fitters has been recruited from the neighbourhood, and these men have proved themselves efficient operators and good timekeepers. The maximum number of drivers employed at the peak was 282, of whom 232 were drawn from the locality. Included in the varied types of haulage which must be co-ordinated in the one organization is the jobbing transport of such loads as railway materials, bricks for the ancillary buildings, plant holding-down bolts, reinforcing steel, shuttering and scaffolding and roadmaking requisites. A large proportion of the 11,000,000 bricks must be double-handled. The reinforcing steel required amounts to 12,500 tons, and there will be 34,000 holding-down bolts in the plant, some of which weigh over a ton each. There are 43 miles of railways, six miles of 22-ft. vibrated-concrete road, and many miles of tarmacadam surfaces.

The general transport work in connection with the drainage and service tunnels is a major job in itself. The area of the basements is 5 acres and the length of the tunnel system is 11,000 ft. '

Flexible Organization

Above all, the organization of the transport fleet has had to remain flexible from day to day since the start of operations. Many details of the foundation and constructional work were formulated as the project progressed, and there have been times when the changeable weather has caused last-minute alterations in arrangements or required an emergency step-up in haulage activities.

The Abbey continuous-strip mill will be the largest in Europe, and to have reached the present advanced stage of .completion in the scheduled time may be considered one of the most important achievements to date in Britain's recovery programme. Extensions to the existing steel works at Margam and the erection of cold mills at Abbey and at Trostre, near Llanelly, are also included in the project, and the total weekly output will be in the region of 20,000 tons of strip and platefrom the Abbey works and 145,000 boxes of tinplate from Trostre works.