The Beaver as an End and Three-way Tipper

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

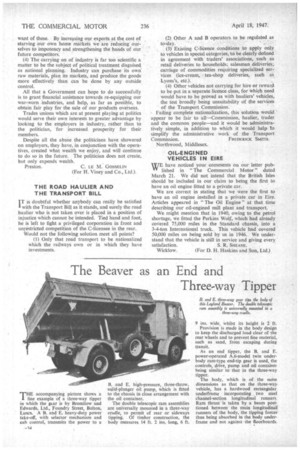

THE accompanying picture shows a fine example of a three-way tipper in which the gtar is by Bromilow and Edwards, Ltd., Foundry Street, Bolton, Lancs. A B. and E. heavy-duty, power take-off, with selector mechanism and cab control, transmits the power to a

B. and E. high-pressure, three-throw, solid-plunger oil pump, which is fitted to the chassis in close arrangement with the oil container.

The double telescopic ram assemblies are universally mounted in a three-way cradle, to permit of rear or sideways tipping. Of timber construction, the body measures 14 ft. 2 ins. tong, 6 ft.

9 ins, wide, whilst its height is 2 ft.

Provision is made in the body design to keep the discharged load clear of the rear wheels and to prevent fine material, such as sand, from escaping during transit.

As an end tipper, the B. and E. power-operated A.6-model twin underbody ram-type end-tip gear is used, the controls, drive, pump and oil container being similar to that in the three-way tipper.

The body, which is of the same dimensions as that on the three-way. vehicle, has a hardwood rectangular underframe incorporating two steel channel-section longitudinal runners. Ram thrust is taken by a beam positioned between the main longitudinal: runners of the body, the tipping forces thus being absorbed in the body underframe and not against the floorboards.