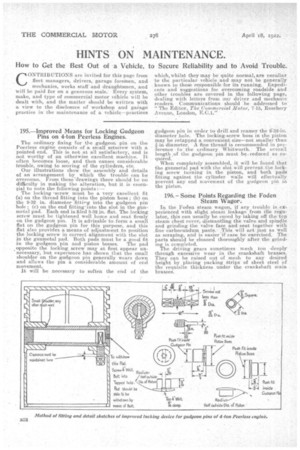

. 195.—Improved Means for Locking Gudgeon Pins on 4-ton Peerless Engines.

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

The ordinary fixing for the gudgeon pin on the Peerless engine consists of a small setscrew with a pointed end. This is not at all satisfactory, and is not worthy of an Otherwise excellent machine. It often becomes loose, and then causes considerable trouble, owing to scoring of the cylinders, etc. Our illustrations show the assembly and details of an arrangement by which the trouble can be overcome. From these drawingsthere should be no difficulty in making the alteration, but it is essential to. note the following points:—

The locking ,screw must be a very -excellent fit (a) on the thread fitting into the piston boss ; (b) on. the 9-32 in. diameter fittieg into the gudgeon pin -hole ; (c) on the end fitting-into the slot in the gunmetal pad. Each end is filed 5-32 in. flat. The locking screw must be tigbtened well home and seat firmly on the gudgeon pin. It is advisable to form a small flat on the gudgeon pin for this purpose, and this flat also provides a means of adjustment to position the locking screw in correct alignment with the slot in the gunmetal pad. Both pads must be a good fit in the gudgeon pin and piston bosses. The pad .opposite the locking screw may at first appear unneeessary, but experience has shown that the small shoulder on the gudgeon pin generally wears down and allows the pin a considerable . amount of end movement.

It will be necessary to soften the end of the

gudgeon pin in order to drill and reamer the 1.32-in. diameter hole. The locking:screw boss in the piston may be retapped a convenient size—not smaller than

diameter. A fine thread is recommended in preference to the ordinary Whitivcirth. The overall length .of the gudgeon pin must be.-reduced as required. When completely assembled, it will be found that the gunmetal pad with the slot will prevent the locking screw turning in the. piston, and both pads fitting against the cylinder walls will effectually prevent any end movement of the gudgeon pin in the piston.

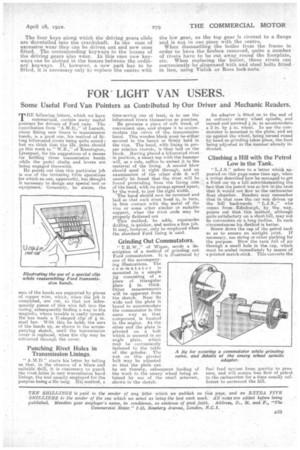

196.Some Points Regarding the FOden Steam Wagor.

in the Foden steam wagon, if any trouble is experienced. with slight steam leakage from die regulator, this can usually be cured by taking off the top steam cheSt cover, dismantling the valve and spindle and grinding the valve face and seat together with fine carborundum paste. This will act just as well as scraping, and is easier if care be exercised. The parts should be cleaned thoroughly after the grinding is completed. The driving gears sometimes mesh too deeply through excessive wear in the crankshaft brasses. They can be raised out of mesh to any desired height by placing packing §:trips of sheet steel of the requisite thickness under the crankshaft main brasses. The four keys along which the driving gears slide are 'dovetailed into the crankshaft. In the case of excessive wear they can be driven out and new ones fitted.. The corresponding keyways in the bosses of the driving gears also wear. In this case new keyways can be slotted in the bosses between the ordinary. keyways. If, however, a new part has to be fitted, it is necessary only to replace the centre with

the low gear, as the top gear is riveted to a flange and is not in one piece with the centre.

When dismantling the boiler from the frame in order to have the firebox removed, quite a number of rivets have to be cut away round the footplate, etc. When replacing the boiler, these rivets can conveniently be dispensed With and steel bolts fitted in lieu, using Vislok or Ross lock-nuts.