Speeding Up 2: Turn-round ,4t Lorries for Suga:

Page 26

Page 27

Page 28

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

W

HAT I have been writing in my current " Solving the Problems of the Carrier " articles about varia tion of rates for local traffic can Well be applied to sugar beet, although it was not that traffic which I selected for an example. There are localities in which sugar beet might be carried at rates lower than for others. Whether the circumstances, in respect .of the carriage of this commodity, are such as to make it impracticable to apply a national scale of rates is a subject which is, as I write, the subject of discussion by th.). interested parties. '

So far as sugar beet is concerned, and especially with regard to the question of rates fixation, a new factor has entered into the problem. It is one .of importance and is likely to be more and more telling in its effects as time goes On. I 'refer to the use of power-driven mechanical loaders for use with the haulage vehicles. . This, of course, is not a new idea. I remember a , mechanical elevator being tried inconjunction with a Sentinel steam wagon some 18 years ago. Other tentative efforts to facilitate lOading by the use of elevators of various kinds have been made fr-om time to time, with varying degrees of success.

The G.W.R. used to employ them to load railway wagons with beet for delivery at the Allscott factory. After a time that company ceased to use them, on the ground that they were costly to maintain. Rumour has it, however, that they fell into disuse for quite another reason, namely, that so much of the dirt fell out of the beet while the loading operation was proceeding.

To appreciate quite what thismeans it must be realized that the railway company is paid per ton of beet and dirt delivered. If most of the dirt be dropped into the railway yard by the mechanism which loads the wagon, the railway company stands to lose 10 per cent, or more of its revenue from the traffic. Of course, that was only a rumour. It is quite possible that the ostensible reason— cost of maintenance— was the correct one.

The record loads, • ,approaching _ 11,000 tons in a season, using six 5-ton lorries, reported in "'The Corn_ mercial . Motor " as having been carried by Messrs. J. and E. Rogers, of Shrewsbury, were made possible only by the use of mechanical loaders. As these loaders do promote economy and save cost in beet haulage, it behoves beet hauliers to appreciate that fact and to make themselves acquainted with the method of use, and especially with the cOnditions which make for economical use of mechanical loaders as well as with conditions Which preclude their satisfactgry employment.

I referred to this subject in the issue of

" The Commercial Motor " dated December 9, 1939. Mr. T. Bates, of Pointon, showed me how he used petrol-engined elevators in conjunction with 1042-ton articulated Cornrners and Leylands. He found the elevator helpful mainly in clearing large heaps of beet: 11 tons of beet can be loaded, in an hour, and that is a considerable saving.

There were, however, certain special conditions prevailing in connection with Mr. Bates's beet-haulage programme, which seemed to me to favour the use of the elevator and would not often be encountered elsewhere. In particular, • he does little short-lead haulage of this commodity : 10 miles is, with few exceptions, the minimum distance.

Hismethod was to take' the elevator--:Shown in one of the accompanying illustrations—and leave it by the heap of beet. Because his distances were medium to long, he rarely loaded more than twice a day from one heap. That being so, he could give the farmer ample notice of his intention to load.The farmer could then conveniently have a man available to help, and expeditious loading was the result.

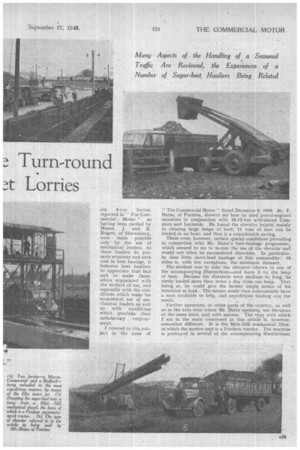

Further operators, in other parts of the country, as well as inthe area near where Mr. Bates operates, use elevators of the same kind, and with success. The type with which I am in the main 'concerned in this • article is, however, somewhat different. It is the Muir-Hill mechanical lifter, of which the motive unit is a Fordson tractor. The machine is portrayed in several of the accompanying illustrations; in its general outline it is familiar to mist commercial-motor users,

Now, the first thing to appreciate abenit this machine is that it costs Money—money to buy as well as to operate. clear ideas are, necessary on that point before going any farther. The initial cost is about 4600. It can be depreciated at about 4100 per annum and its maintenance cost will probably be in the neighbourhood of 430 per annum throughout its life. It costs 10s. a day for fuel and oil, say 43 10s, per week for wages, and, approximately, 410 per annum for tyres. Taxation is 425 per annum if, as must be the case for economical operation, it is used on the roads.

Its employment is not confined to the loading of sugar beet: Most operators use it for loading coal, lime, stone and other similar traffics. It can, therefore, be said to cost approximately .47 per week for standing charges, say, 41 per week for overheads, plus 10s. per day for fuel and oil. Reckoning a 5f-day week, that is approximately 42 per day. (It is impossible to give more accurate figures.) Clearly, if the machine is to pay its way and prove its worth, it must be employed to a reasonably continuous extent throughout each wgrking day. Obviously, that cannot be arranged if the beet be available for loading in only small quantifies. Equally obvious is it that it is .necessary to use several lorries in conjunction with the one loader.

Experienced operators, Mr. E. Hemmings and Mt. H. A. L. Price amongst them, agree that the minimum weight of beet in a heap to which it pays to take a mechanical loader is 40 tons. • If the heap be upwards of 100 tons that is better. As to the number of lorries to be used in conjunction with a loader, that varies according to the distance between the heap of beet and the factory. Mr. Price uses six 5-ton lorries in connection with a 14-miles lead.

The following are figures for beet tonnages moved by Mr. Price, using a Muir-Hill loader, in 12 consecutive days:-119, 134i, lsol, 158f, 152, 124, 133. 112, 130, 131,

100, 136. The lead distance was 15 miles and six 5-5f-ton lorries were employed. The beet.was well laid on a hard base and so disposed that the shovel was able to start at one end and work up to the other. A 5-51-ton lorry can be loaded in 12 minutes with a loader. .When loaded by .hand it. usually takes two men an hour to an hour-and-aquarter.

• The point about the beet being well laid .on a hard bale is worthy of note. Both these operators, and others I have interviewed, were emphatic on that point. If the ground be soft, there is a tendency for the shovel to pick up too much dirt with the beet. Moreover, in wet weather, the tractor wheels cut up the ground about the heap of beet and in that way cause annoyance to the farmer.

How to Work a Loader for Obtaining the Best Results . Mr, Price gave me another example of the way in which to operate a loader to best advantage. He mentioned an instance when a heap of beet was located on the road between his premises, at Daw/ey, and Wolverhampton. He was at that time carrying traffic regularly for Wolverhampton and four lorries were loaded overnight for that journey. They set out early the next morning. At the same time two other lorries and the mechanical shovel were dispatched to the heap. of beetBy the time the first two lorries Were loaded and away, the first of the four from WolverhaMpton had returned to be followed in quick succession by the other three so that the six loraies were soon fully operating, which they continued to do for the rest of the day.

In discussing the operation of vehicles with a loader, Mr. Price emphasized that it is necessary to 'make it quite clear to the lorry drivers that they are not to wait for one another. So soon as one lorry is loaded the driver must get away to the factory. If this recommendation be not -followed then the whole organization of the scheme, which

depends for its success upon a regular sequence of loadings, will be upset.

A point which arises with reference to the minimum quantity of 40 tons per heap of beet is that, according to the ordinary method of issuing permits to the farmers it might not be permissible for the haulier to continue to unload a heap of this or greater size without a break. To assist operators, however, the factory will usually agree to exchange permits, so that the sugar .beet from one heap can be taken continuously; the haulier can then change over to collect from another farmer who also has a load suitable for collection according to this improved method.

In addition to the figures I obtained for loading time,. two operator .friends of mine gave me these instances: (a) six tons loaded in 12 minutes; (b) loading 4 tons 3f cwt. needed 15 shovel loads and was completed in eight _minutes; (c) 5 tons 14 cwt. loaded in 20 minutes.

Mr. J. F. Smith uses four lorries for a lead of 16 miles: Mr. S. J. R. Atkins uses 9 or 10 lorries over a lead of 15 miles. An important point to note is that undue delay at the factory may completely upset the schedule. I made a personal test of loading time on the farm of 'Mr. Everall. The lorry and the loader were both the property of Mr. E. E Rogers. The lead distance was 16 miles: the load was 5 tons 14 cwt.: time to load, 16 minutes "(18 shovel loads): time travelling to factory 41 minutes: time in factory yard, weighing-in, unloading, weighing out, 16 minutes: time returning to heap of beet 40 minutes. This represents a total time of 1 hour 53 minutes It means that four loads can be conveyed per day, as against two without the help Of the loadei.

. That gives us a basis for costs comparison Assume six vehicles on a 16-miles haul. The standing charges per vehicle will be: Licence, 14s.; wages and insurance, etc.— two men—£8 es.; rent and rates, 5s.; insurance, 16s ; interest on capital, 10s.; total, £10 10s; Adding establishment costs, say £2 10s., gives a total of fixed costs of £13.

The running costs per mile will be: fuel 'A 4d.; oil, 0 18d.; tyres, 0.80d.; maintenance, 1.20d ; depreciation 1.12d The total is 5.76d. A lorry running two journeys per day, 64 miles each day, will cover 384 miles per week, so that the running costs will be E9 2s. 4d., and the total weekly expenditure £22 Zs. 4d.

For that, the tonnage carried will approximate to 70 (about 51 tons per load), so that the cost to the haulier is 6s. 31d. per ton; he must obtain Rs, per ton for the work. When a loader is used the tonnage carried is doubled, the cost is increased (a) by the cost of operating the shovel and (b) because the mileage also is doubled.

The cost of the shovel I have shown to be £2 per day, or £12 per week. As .six lorries are employed this cost must be shared equally between them. That means that

the weekly total of fixed charges per lorry is increased from £13 to £15. The running costs become £18 4s. 8d.,

so that the total expenditure is £33 4s. 8d. That is for 140 tons, so that the cost per ton to the operator is reduced to 4s, 9d. It is important to give the factory point of view about the use of these mechanical loaders. In the first place, it should be made clear that anything which will expe dite the delivery of sugar beet is welcomed by the factory, so that in criticizing the use of the mechanical shovel those responsible may be taken to be doing so in a friendly spirit. The following is the resultof an interview with a nianager of one of the sugar-beet factories.'

He says that a disadvantage of the mechanical Shovel is that more dirt is delivered with the

beet. Dirt means trouble in the factory. This comes about (a) because when the beet is hand loaded, using a fork, a considerable proportion of the dirt is shaken off in the process of loading, and (b) the mechanical shovel picks up dirt from the ground which the fork does not.

The Weight Allowance for Dirt in the Load The normal allowance for dirt lying upon the floor of the lorry, which is-debithl against the farmer breach load of beet, is at the rate of 2 lb. tare per cwt. The actdal quantity of dirt is much more than that, as in the case on recordduring the previous campaign, when the dirt revealed in the sample was in the proportion of 73 lb. per cwt. As a rule there is dirt still remaining in the vehicle, to the weight of, perhaps, one or two cwt. after the load has been discharged.

With the mechanical loader the amount of dirt per cwt. increases as the heap of beet diminishes. Out of seven conSecutive loads from the same farmer the amount of dirt per. cwt. rose from 1 lb. to 29 lb.; in the sixth load there was 11 lb. and in the seventh, 29 lb. I may say that I observed this myself in the course of watchiqg the loading of the beet at Mr. Everall's farm, as described above.

At the beginning, the shovel was on the clean turf, but

as time wore on the earth was broken up and I. could see that the tendency was for more and more dirt to be picked Up as the heap diminished.

The cheek on the percentage of dirt which is normally debited to the farmer, in addition to the 2 lb. per cwt. 'tare mentioned, is by sampling. Some of the beet is taken from the rear of the load, a sampling bucket is then placed on the floor and the beet scraped into the bucket.

In this way it is possible to get a reasonably accurate figure for the propoftion of dirt in the beet loaded into the vehicle. When the dirt is excessive, however, much of it is shaken down to the floor of the vehicle and no evidence of this appears as the result of sampling. That is intended to be provided for in the allowance of 2 lb. per cwt. -tare, which is additional to what is shoWn by sampling.

This factory manager told me most emphatically that he objects to paying £4 to £5 per ton for dirt.

With a mechanical loader, as has been stated, the tendency is for the proportion of dirt to increase and, Unfortunately, most of it does fall to the floor of the vehicle. With the spreading ofmechanical loading it is possible that the factory may have to revise this tare figure in an upward direction.

Another point which must be borne in mind is the risk, when the beet is hand unloaded, that the.haulier may forget to clear the lorry with each successive load so that, as load follows load, the amount of dirt which is weighed steadily increases. It is possible to arrange for the vehicles to be cleaned before they leave the factory. On the other hand that does not always please the farmerS, who sometimes prefer that the soil should be taken back and replaced on their own fields. In the previous campaign, no less than 17,000 tons of dirt was delivered to the factory with the beet and this is actually being used for levelling the ground around the factory.

This factory manager concluded by expressing the hope and belief that operators would do what they could to` diminish the tendency to pick up dirt with the shovel.

Actually experiments in this direction were being carried out by various operators at the time of 'my visit. Both . Mr. Price and Mr. Hemmings were trying the effect of fitting slats on the bottom of the shovel, so as to lift it from the ground. Mr. Atkins, another operator, says he is arranging for the Muir-Hill concern to supply him with a bucket with slats in the base Instead of a solid sheet of metal, as is now customary, so that the dirt will fall

through. He also is fitting skids to lift the base of the bucket off the ground when in use.

It is pointed out that the farmer can also help by taking care to put his heaps of beet on hard ground, where there

Is less likelihood of dirt being picked up. It has been suggested that lie should concrete a suitable area, for the reception of his beet, but the objection to such a course is that the beet is not grown in the same fields in successive years and a place for storage which might be convenient for one year would be extremely inconvenient the following season.