New Albion Bus Chassis for Overseas

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

AN important place in the export market has always been held by Albion Motors, Ltd., Scotstoun, Glasgow, W.4, and the vehicles produced for this purpose have won a remarkable reputation for clean design and long working life.

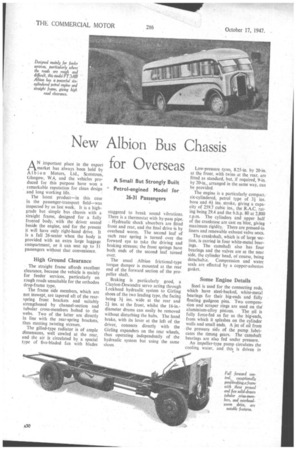

The latest product—in this case in the passenger-transport field—was inspected by us last week. It is a highgrade but simple bus chassis with a straight frame, designed for a fully fronted body, with the driver seated beside the engine, and for the present it will have only right-hand drive. It is a full 26-seater when the body is provided with an extra large luggage compartment, or it can seat up to 31 passengers without that convenience.

High Ground Clearance

The straight frame affords excellent clearance, because the vehicle is mainly for feeder services, particularly on rough roads unsuitable for the orthodox drop-frame type.

The frame side members, which are not inswept, are tapered aft of the rearspring front brackets and suitably strengthened by channel-section and tubular cross-members bolted to the webs. Two of the latter are directly in line with the rear-spring brackets, thus meeting twisting stresses.

The gilled-type radiator is of ample dimensions, well cowled at the rear, and the air is circulated by a special type of five-bladed fan with blades staggered to break sound vibrations. There is a thermostat with by-pass pipe.

Hydraulic shock absorbers are fitted front and rear, and the final drive is by overhead worm. The second leaf of each rear spring is turned over the forward eye to take the driving and braking stresses; the front springs have both ends of the second leaf aimed Over.

The usual Albion frictional-type torque damper is mounted at the rear end of the forward section of the propeller shaft.

Braking is particularly good, a Clayton-Dewandre servo acting through Lockheed hydraulic system to Girling shoes of the two leading type, the facing being 31 ins, wide at the rear and 21 ins, at the front, whilst the 16-in.diameter drums can easily be removed without disturbing the hubs. The hand brake, with its lever at the left of the driver, connects directly with the Girling expanders on the rear wheels, thus operating independently of the hydraulic system but using the same shoes. Low-pressure tyres, 8.25-in. by 20-in. at the front, with twins at the rear, are fitted as standard, but, if required, 9-in. by 20-in., arranged in the same way, can be provided.

The engine is a particularly cotnpact,. six-cylindered, petrol type of 31 ins. bore and 41 ins, stroke, giving a capacity of 259.7 cubic ins., the R.A.C. rating being 29.4 and the b.h.p. 80 at 2,800 r.p.m. The cylinders and upper half of the crankcase are cast en bloc, giving maximum rigidity. There are pressed-in liners and renewable exhaust valve seats.

The crankshaft, which is of large section, is carried in four white-metal bearings. The camshaft also has four bearings and the valves are at the near side, the cylinder head, of course, being detachabie. Compression and water seals are effected by a copper-asbestos gasket.

Some Engine Details

Steel is used for the connecting rods, which have steel-backed, white-metal bearings for their big-ends and fully floating gudgeon pins. Two compression and scraper rings are used on the aluminium-alloy pistons. The oil is fully force-fed as far as the big-ends, from which it splashes on the cylinder walls and small ends. A jet of oil from the pressure sid.t of the pump lubricates the timing gears. The camshaft bearings are also fed under pressure.

An impeller-type pump circulates the cooling water, and this is driven in tandem with the dynamo at the near side of the engine. A spring-loaded carbon gland minimizes the need for attention to the pump. Endless rubber belts drive the fan, dynamo and water ppmp, the fan spindle being eccentrically mounted for adjustment.

Carburation is by a downdraught Zenith with an induction-pipe hot spot and a large oil-bath air cleaner. The ignition timing is automatic.

Ample fuel capacity is provided by a /5-gallon cylindrical tank mounted at the off side on frame outriggers and feeding through an Amal pump.

A clutch of the single dry-plate type with a renewable friction ring on the. flywheel, and a spigot running in a ballbearing in the crankshaft which is lubricated automatically from the gearcase, takes the drive to a unit-mounted gearbox affording four forward speeds, the ratios being: first, 6.59 to 1; second, 3.24 to I; third, 1.71 to 1. The gear lever is mounted on the top of the clutch housing at the left of the driver.

Open Propeller Shaft

The propeller shaft is open, and the rear end of the front section is carried in a self-aligning bearing mounted on a cross-member. The joints are Hardy Spicer with needle-roller bearings. The rear axle is fully floating and the body is a one-piece forging of alloy steel. The whole worm and differential assembly can be withdrawn without removing the road wheels, and if there be any failure in this part, the driving shafts can be withdrawn and the vehicle towed.

Hubs and differential •are all carried on taper roller bearings, whilst the worm housing has taper roller thrust and roller journal bearings.

An alloy-steel forging with a high safety factor is used for the front axle, the pivot pins of which are mounted in p Lain bushes.

Suspension System

The rear springs are progressive and are 4 ft. 6 ins, long, whilst those at the front have a length of 3 ft. 10i ins.

Steering is effected through a Mantes cam-and-lever type gear. The column is arranged so that the ball pin on the steering arm is in front of the axle, the connecting Tod running back to the pin on the stub arm. This obviates the transmission of road shocks to the steering wheel. The wheels are of the detachable steel-disc type. Chassis lubrication employs the Tecalemit oil gun system. The 12-volt electrical equipment has compensated voltage control dynamo.

The following are the leading dimensions:—Wheelbase, 15 ft. I li ins.; ground clearance under rear axle, II ins. (with standard smaller tyre equipment); turning circle, 56 ft. Approximate weight, 2 tons 15i cwt.

As regards information concerning export and shipping; when the chassis is dismantled as far as practicable, the approximate dimensions of the packing case are:—Length. 25 ft; breadth, 3 ft. 4 ins.'; height, 3 ft. 6 ins.; volume, 291. cubic ft. The chassis, packed weighs approximately 3 tons 6 cwt., and the shipping weight, at 40 cubic ft. per ton, is 7 tons 6 cwt.