Wise Spending to Rejuvenat DM Timers

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

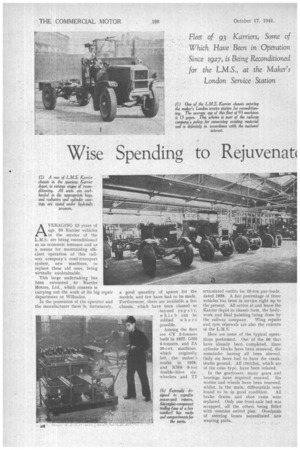

AVERAGING 13 years of age, 93 Harrier vehicles in the service of the L.M.S. are being reconditioned as an economic measure and as a means for maintaining efficient operation of this railway company's road-transport system, new machines, to replace these old ones, being virtually unobtainable.

This large undertaking has been entrusted _ to Harrier Motors, Ltd., which concern is carrying out the work at its big repair department at Willesden.

In the possession of the operator and the manufacturer there is, fortunately,

a good quantity of spares for the models, and few have had to be made, furthermore, there are available a few chassis, which have been classed as

, beyond repair, which can be robbed where possible.

Among the fleet are CY 2-tonners built in 1927, GH5 4-toriners, and ZA 30-cwt. machines, which originally left the maker's works in 1928, and KW 6 8-ton double-drive six, wheelers and TT

articulated outfits for 10-ton pay-loads, dated 1929. A fair percentage of these vehicles has been in service right up to the present. All arrive at and leave the Harrier depot in chassis form, the bodywork and foal painting being done by the railway company. Wing repairs and tyre. renewals are also the concern of the L.M.S.

Here are some of the typical operations performed. Out of the 60 that have already been completed, three cylinder blocks have been renewed, the remainder having all been sleeved. Only six have had to have the crankshafts ground. All clutches, which are of the cone type, have been 'refaced,

, In the gearboxes, many gears and. bearings have required renewal. Six worms and wheels have been renewed, whilst, in the main, differentials were

found to be in good condition. All brake drums and shoe cams were replaced. Only one front-axle bed was scrapped, all the others being fitted with Oversize swivel pins. Overhauls of steering boxes necesSitated neW wearing parts. As regards frame parts, a consider. able number of new spring brackets was required, most of the brake shafts had to be replaced, and hand-brake parts needed general rentwal. All radiators were stripped and tested under hydraulic pressure. By this means, many leaks were revealed, which called for considerable rebuilding.

Springs in every case were taken down, checked, and set up, this work being entrusted to Transport Engineering, Ltd.

Some of the chassis were equipped with oil lamps, and electric-lighting' systems have been installed.

References above to renewal and new parts do not necessarily mean that the old ones were scrapped. In the majority of cases, we understand, the worn parts could be salvaged by building up by welding. Spring brackets. for example, were widely rendered serviceable by this process, the welding being done by the Blaker Motor and Welding Co., Ltd., and the subsequent machining being carried out by Karrier Motors, Ltd.

Contact with the progress of the operations in hand has been kept all along by an L.M.S. inspector. This arrangement, Mr. Lester, manager of the Harrier London Service Station, 'told us, has been most satisfactory and has helped greatly, notably in determining what parts to renew and what to pass as fit for further service.

Moreover, it has simplified the problem of obtaining spares, some of which, as mentioned already, have come from the L.M.S. stores. The two companies have indeed co-operated very closely on

this job from the period when Mr. Shearman, chief of the L.M.S. Road Motor Department, -first proposed it to Mr. Cozens, deputy managing director of Karrier Motors, Ltd.

Whilst reconditioning solves the problem of vehicle shortage, it does not get over the difficulty of scarcity of labour. Therefore, the Karrier concern has employed a fair number of men from Government training centres and a proportion of female labour, notably for lighter work, such as pain t spraying, issuing stores and tools, etc.

As an instance of t h e thoroughness with which this job is being tackled, mention may be made of the fact that a new inspection schedule was drawn up, so that a final check on every chassis could be made after the overhaul was completed. On it there were 70 items. Representative are such points as these :,—Tighten cylin der-bead nuts, check oil pressure, check amount of brake rod screwed into turnbuckle, check dynamo charging rate, fill oil cups on swivel pins. These seems little likelihood of anything being wrong with a chassis that has been approved according to this schedule.

Methodical arrange in en ts are, obviously,, equally essential to the effecting of the work from the outset, btit this presents no new problem, because these Karrier chassis just go through in accordance with the regular routine of the establishment, which has been thoroughly developed.