Vehicles in the Trials.

Page 3

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

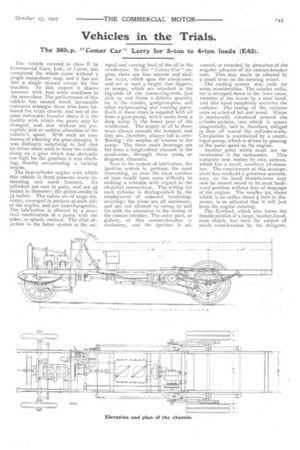

The 36h.p. "Corner Car" Lorry for 5-,ton to 4-ton loads (E43)1 Tim vehicle entered in class E by Commercial Cars, Ltd., of Luton, has completed the whole toute without a single compulsory stop, and it has not lost a single minute except for tire troubles. In this respect it shares honours with four other machines in the same class. The performance of this vehicle has caused much favourable comment amongst those who have followed the trials closely, and one of the most noticeable features about it is the facility with which the gears may be changedl and that without any perceptible jerk or sudden alteration of the vehicle's speed. With such an easy means of effecting the gear-changes, it was distinctly surprising to find that its driver often tried to force the vehicle along on a gear which was obviously too high for the gradient it was climbing, thereby necessitating a tacking course.

The four-cylinder engine with which this vehicle is fitted presents many interesting and novel features. Its cylinders are cast in pairs, and are 41 inches in diameter ; the piston-stroke is si inches. The valves are of large diameter, arranged in pockets at each side of the engine, and are interchangeable. The lubrication is effected by a practical combination of a pump with the older, or splash, method. The chief objection to the latter system is the un

equal and varying level of the oil in the crank-case. In this " Comer Car "engine, there are four narrow and shallow trays, which span the crank-case, and are at. such a height that dippers, or scoops, which are attached to the big-ends of the connecting-rods, just pick up and throw a definite quantity on to the cranks, gudgeon-pins, and other reciprocating and rotating parts. Each of these trays is supplied with oil from a gear-pump, which sucks from a deep sump in the lower part of the crank-case. The supply of oil to these trays always exceeds the demand, and they are, therefore, always full to overflowing : the surplus oil returns to the sump. The three main bearings are fed from a longitudinal channel in the crank-case, through three cross, or diagonal, channels.

Next to the system of lubrication, the ignition system is, perhaps, the most interesting, as even the most careless of men would have some difficulty in making a mistake with regard to the electrical connections. The wiiing, for each cylinder is distinguished by the employment of coloured insulatingcovering ; the wires are all stationary, and are not allowed to swin.g to and fro with the alteration in the timing of the contact-breaker. The outer part, or gallery, of this contact-breaker is stationary, and the ignition is ad

vanced, or retarded, by alteration of the angular advance of the contact-breaker cam. This may easily be effected by a small lever on the steering wheel.

The cooling system also calls for some consideration. The tubular radiator is strapped down to the front cross_ member of the frame by a steel band, and this band completely encircles the radiator. The casing of the radiator rests on a bed of fell and wood. Water is continually circulated around the cylinder-jackets, into which it enters tangentially, and is, therefore, obliged to flow all round the cylinder-walls. Circulation is maintained by a centrifugal pump, which is driven by gearing at the same speed as the engine.

Another point which must not be overlooked is the carburetter. This company now makes its own pattern, which has a small, auxiliary jet-chamber. The employment of this arrangement has rendered a governor unnecessary, as the hand throttle-lever may now be moved round to its most backward position without fear of stoppage of the engine. The smaller jet, above which is an orifice about inch in diameter, is so adjusted that it will just keep the engine running.

The flywheel, which also forms the female portion of a large, leather-faced, cone clutch, has been the subject of much consideration by the designer,

especially as regards its method of connection to the crankshaft. The latter terminates in a T-shaped flange, which fits in a recess in the back of the flywheel, and the two bolts which

hold the flywheel in this position are thus relieved of all shearing strains. No keys are employed in this vital part of the chassis, and the male portion of the clutch is made in halves so as to facilitate the renewal of the leather facing when worn.

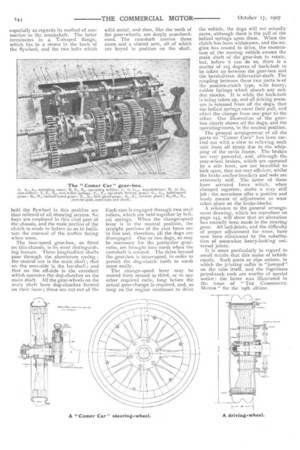

The four-speed gear-box, as fitted on this chassis, is its most distinguishing feature. Three longitudinal shafts pass through the aluminium casing : the central one is the main shaft ; that on the near-side is the lay-shaft; and that on the off-side is the camshaft which operates the dog-clutches on the main shaft. All the gear-wheels on the main shaft have dog-clutches formed on their faces ; these are cut out of the

solid metal, and then, like the teeth of the gear-wheels, are deeply case-hardened. The camshaft carries three cams. and a slotted arm, all of which are keyed in position on the shaft.

Each cam is engaged through two steel rollers, which are held together by helical springs. When the change-speed lever is in the neutral position, the straight portions tyf the cam faces are in line and, therefore, all the dogs are disengaged. One or two dogs, as may be necessary for the particular gearratio, are brought into mesh when the camshaft is rotated. The drive beyond the gear-box is interrupted, in order to permit the dog-clutch teeth to mesh more easily.

The change-speed lever may be moved from second to third, or to any other required ratio, long before the actual gear-change is required, and, so long as the engine continues to drive the vehicle, the dogs will not actually move, although there is the pull of the helical springs upon them. When the clutch has been withdrawn, and the engine has ceased to drive, the momentum of the moving vehicle causes the main shaft of the gear-box to rotate, but, before it can do so, there is a matter of 22i degrees of back-lash to be taken up between the gear-box and the bevel-driven differential-shaft. The coupling between these two parts is of the positive-clutch type, with heavy, rubber facings which absorb any sudden shocks. It is while, the back-lash is being taken up, and all driving pressure is released from off the dogs, that the helical springs exert their pull, and effect the change from one gear to the other. Our illustration of the gearbox clearly shows all the dogs, and the operating-cams, in the neutral position.

The general arrangement of all the parts on "Corner Cars" has been carried out wiith a view to relieving each unit from all strain due to the whipping of the main frame. The brakes are very powerful, and, although, the rear-wheel brakes, which are operated by a side lever, are not beautiful to look upon, they are very efficient, whilst the brake anchor-brackets and rods are extremely stiff. The latter of these have serrated faces which, when clamped together, make a very stiff job the serrations offer a positive and ready means of adjustment as wear takes place on the brake-blocks.

A reference to the general arrangement drawing, which we reproduce on page 143, will show that an alteration has recently been made in the steering gear. All ball-joints, and the difficulty of proper adjustment for wear, have now been eliminated by the substitution of somewhat heavy-looking universal joints.

It is more particularly in regard to small details that this make of vehicle excels. Such parts as pipe unions, in which the jointing collar is "jumped" on the tube itself, and the ingenious petrol-tank cock are worthy of special notice : the latter was illustrated in the issue of "THE COMMERCIAL MOTOR" for the 10.11 ultimo.