2II& °IFON CII L

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

0••■••••

ISTORY was made in Mow Cop, a strange,

granite hamlet, perched over 1,000 ft. above sea

Level on a wild promontory overlooking the smooth Cheshire plain, when the E.R.F. overseas sixwheeler, weighing almost 21i tons gross, climbed the 1-in-3.8 gradient that has defeated so many vehicles in the past. The local archives kept in the " Railway Inn." show that Mr. E. R. Foden, managing director of E.R.F., Ltd., was the first man to drive a car up this formidable hill. It was therefore appropriate that one of his products should be the largest ever to reach the settlement of Mow Cop.

The unusual sight of a photographer setting up his camera in the street caused inquiring heads to pop out of cottage doors and windows. The roar of the Gardner 6LW engine in the still, barren country, brought the villagers scurrying from their houses, and the children and their master from the little school, to witness the finest &ash that Mow Cop had ever known. They took up their stand outside the " Railway Inn," where thz gradient suddenly increases from 1 in 5 to 1 in 3.8. This is where the best local accidents had taken place.

As we reached the inn, the works driver changed from second-low to bottom gear, and for a second the Chassis halted. This was the moment the villagers had been waiting for. The bets were about 100 to 1 against the vehicle's pulling away, and 100 to 1 on its careering backwards down the hill and through one of the rough stone walls that bordered the road.

B12

The onlookers were astounded, and perhaps a trifle disappointed, when the E.R.F. continued to nose it way towards the sky. Possibly the only gratified witness was Mr. Foden, who had rocketed up the hill in his 2-litre Bristol to mark the event in the local historical records, Expectation of the accident of which the villagers had been cheated was high when we backed down the hill to attempt the impossible by climbing in secondlow ratio. The engine shuddered on NI torque, and finally stalled—again outside the " Railway Inn." The natives were bubbling with excitement, and babbling [heir conviction that the crash was really coming. The

fin

brakes, they were certain, would never hold such a weight. For the second time they were wrong_ This was the highlight of a day made momentous for reasons apart from the conquest of Mow Cop. It was the first occasion on which a technical journalist had been allowed to test an E.R.F. vehicle. It was also the first Press trial of the Gardner 6LW engine in its latest form and uprated to 112 h.b.p.

Modifications to the power unit to bring it to its present rating include a new exhaust manifold to give higher volumetric efficiency, and improved scavenging. Alterations to the injector and injection-pump setting have "had a substantial influence on the combustion characteristics, thereby affording greater economy and reducing ignition noise.

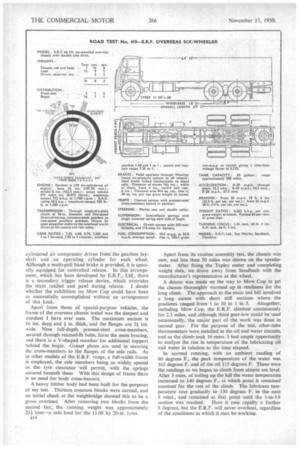

Equipped for operation in hot countries, the engine lubrication system, as fitted to the E.R.F., has an external oil cooler comprising 12 flat tubes placed horizontally in front of the normal water-cooling radiator. Oil is circulated by an independent pump driven from the fuel-injection pump camshaft. •

The power unit, together with the clutch and gearbox, is mounted at the front, on two rubber-bushed links, whilst the rear is suspended from a Metalastik rubberbonded sandwich unit, which is carried by a crossmember above the flywheel housing. To restrict torquereaction movement, there are two rubber-bushed links, one to each side of the flywheel housing, which are disposed to give increased snubbing action when full torque is imposed.

Because the gearbox is attached to, and oscillates with, the engine, the remote-control gear lever is attached to the side of the crankcase. The auxiliary gearbox, however, is suspended independently from the chassis frame, and its operating lever is attached to the main side member. Dust excluders are fitted to the change-speed shaft at all points where it passes through bearings. The David Brown five-speed close-ratio constant-mesh gearbox is used, and coupled by a short shaft to a two-speed auxiliary box. This has ratios of 1.58 and 1 to I, and in conjunction with the normal box gives a selection of 10 forward and two reverse ratios.

Both axles of the bogie are driven by overhead worm gear, and to afford maximum traction on soft ground, there is no intermediate differential between the axles. The bogie employs a single inverted spring at each side, and torque reaction is absorbed by rubber-bushed rods between the axles and chassis frame.

The Westinghouse b'raking system includes a twots13 cylindered air compressor driven from the gearbox layshaft and an operating cylinder for each wheel. Although a multi-pull hand brake is provided, it is specially equipped for controlled release. In this arrangement, which has been developed by E.R.F., Ltd., there is a secondary trigger release device, which overrides the main ratchet and pawl during release. I doubt whether the exhibition on Mow Cop could have been so successfully accomplished without an arrangement of this kind.

Apart from those of special-purpose vehicles, the frame of the overseas chassis tested was the deepest and sturdiest I have ever seen. The maximum section is 16 ins, deep and I in. thick, and the flanges are 31 ins. wide. Nine full-depth pressed-steel cross-members, ;ecured through reamed-fit bolts, form the main bracing, Ind there is a V-shaped member for additional support behind the bogie_ Gusset plates are used in securing the cross-members to the flanges of the side rails. As in other models of the E.R.F. range, a full-width frame is employed, the side members being as widely spaced as the tyre clearance will permit, with the springs secured beneath them With this design of frame there is no need for body cross-bearers.

A heavy timber body had been built for the purposes of my test. Thirteen concrete blocks were carried, and an initial check at the weighbridge showed this to be a gross overload. After removing two blocks from the second tier, the running weight was approximately 21i tons—a safe load for the 11.00 by 20-in. tyres.

a14 Apart from its routine assembly test, the chassis was new, and less than 50 miles was shown on the speedometer. After fixing the Tapley meter and completing weight data, we drove away from Sandbach with the manufacturer's representative at the wheel.

A detour was made on the way to Mow Cop to get the chassis thoroughly warmed up in readiness for the long climb. The approach to the main test hill involved a long ascent with short stiff sections where the gradients ranged from 1 in 10 to 1 in 5. Altogether, including Mow Cop, the E.R.F. climbed continuously for 2.3 miles, and although third gear-low could be used occasionally, the major part of the work was done in second gear. For the purpose of the test, ether-tube thermometers were installed in the oil and water circuits, and as the climb took 16 rnins. I had ample opportunity to analyse the rise in temperature of the lubricating oil and water in relation to the time elapsed.

In normal running, with an ambient reading of 60 degrees F., the peak temperature of the water was 163 degrees F. and of the oil 115 degrees F. These were the readings as we began to climb from almost sea level. After 3 mins. of toiling up the hill the water temperature increased to 140 degrees F., at which point it remained constant for the rest of the climb. The lubricant temperature rose gradually to 130 degrees F. in the next 8 mins., and remained at that point until the 1-in-3.8 section was reached. Here it rose rapidly a further 8 degrees, but the E.R.F. will never overheat, regardless of the conditions in which it may be working. At first I was unconcerned about the descent, having complete confidence in the brakes. I had not, however, foreseen that the payload might shift when negotiating the steep decline at the "Railway Inn." It was by chance that 1 glanced through the rear window and observed the top tier of the payload inching forward. Fortunately the driver had made a safe choice by selecting a low gear, and was using the engine as a brake. The load steadied as the country flattened and, except that great caution had to be exercised when negotiating the steeply cambered corners, no further difficulties were encountered.

To complete the niorning's work, I drove the E.R.F. up Tor Hill, a climb well known to all long-distance drivers. Unless the road is clear and the gearbox used suitably, the driver of the heavy vehicle is faced with a three-mile climb in low gear. After jockeying for position I managed to get a good start and climbed the gradient in second and third gears of the main gearbox. Lubricant temperatures taken at the top of the hill showed the centreaxle reading to be 173 degrees F. and that of the rear axle 188 degrees F.

An initial consumption trial over a 40-mile outand-return course was marred by a fuel leakage which developed during the run, although this 40 miles at least helped running-in and reduced friction losses. A further 37 gallons of fuel were then added to the main tank for a repeat test, this time using the normal supply system. This brought the running weight up to 2li tons precisely. A close check was kept on the fuel during the second trial, which was made over an average course.

Traffic-light delays and halts at major roads produced an average of one stop for every four miles, the mean speed working out to 21.8 m.p.h. The fuelconsumption rate of 10.5 m.p.g. for a new vehicle of 21i tons gross is exceptionally economical, and the maker's claim of 10-12 m.p.g. under general conditions appears to be reasonable. This gives a time-load-mileage factor of 5,132.

The short performance trials were made in two directions on the Middlewich-Holmes Chapel road. Because of the axle ratio (7.25 to 1) and engine governor setting, the maximum speed of the test vehicle was 28 m.p.h. Braking tests were, therefore, made at 20 m.p.h. and 25 m.p.h., and the acceleration trials at speeds up to the governed limit.

In the first braking tests, the vehicle came to rest in less than 20 ft. from 20 m.p.h. fortunately, the payload did not move Repeat tests at intervals, until the brake drums became hot, showed no tendency to fade. Duron brake facings are used and the shoes are cam operated.

The extra power developed by the Gardner modified unit showed to advantage in the acceleration tests, when, employing normal changes, we reached 20 m.p.h. from rest in 32.2 secs.

I drove to Sandbach Green, a large, cinder-surfaced parking ground, to measure the turning circles. Despite its long wheelbase, the E.R.F. is manceuvrable and the turning circles, measured over the extremities of the tvre marks, were, right-hand lock 66 ft. 5 ins., and left-hand 68 ft. 4 ins.

travelled over 100 miles in the vehicle and enjoyed every moment. The E.R.F. has delightfully light steering and the close-ratio gearbox affords a lively performance with rapid changes. Undoubtedly, the quick change from direct drive to fourth and third gears contributes to economy.

As an overseas model the E.R.F. 66 E.A. has an allsteel cab. This is roomy and well ventilated, and a further noteworthy point is that the bonnet does not become overwarm during continuous hill-climbing. The fittings of the cab and instrument panel are part of the vehicle, which is beyond my criticism.