MAXIMUM TR ON-MAXIMUM ARTICULA HON

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

By JOHN F. MOON, A.M.I.R.T.E. ONE of the disadvantages of single-drive bogies is that of occasional driving-wheel spin, particularly when roads are slippery and also on steep, badly surfaced gradients. Various ways of trying to overcome this have been thought up over the years, the prime object being to distribute the rear-bogie loading so that the driving wheels bear a higher proportion of the imposed weight.

One of the most commonly employed methods used with four-spring bogies is to have balance beams with noncentral pivots so that the load on the driving axle is greater than that on the trailing axle. With two-spring bogies, however, a satisfactory solution is more difficult to provide, and an interesting approach has just been made by Seddon Diesel Vehicles Ltd. who have developed a simple system using air-pressure load-transfer cylinders which act on the driving axle and are under the direct control of the driver.

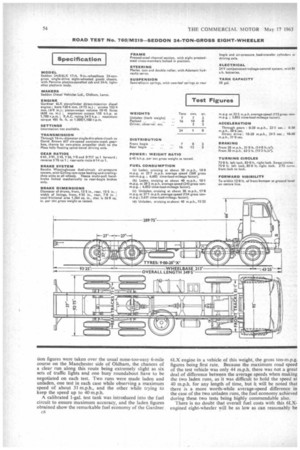

At an air pressure of 105 p.s.i., each of the 4-in.-bare cylinder assemblies can exert a downward force of 1,320 lb., so adding 1 ton 3-5 cwt. to the driving-axle load. Because this has the effect of reducing the trailing-axle load by the same amount, the net result is that the wheel loadings of the driving axle become 2 ton 7 cwt. higher than the loadings of the trailing axle when the cylinders are in use and extra traction is required. With no air pressure in the cylinders the two axle loadings are equal, of course.

The cylinders are attached to the insides of the chassisframe side members, whilst the lower ends of the piston rods are pinned to brackets on the axle case. The piston has a stroke of 7-5 in., thus the load-transfer cylinders do not restrict the good articulation of the Seddon twospring bogie, which allows a diagonal articulation of up to 11 in. The valving of the system feeding the cylinders is such that full movement is retained when the control valve is open, air spilling out of the cylinders if the pistons go up, and pressure automatically being restored as the pistons go down. Thus, the load-transfer effect is not lost when the axles are articulating.

Valuation tests with the new Seddon load-transfer system formed part of a road test 1 carried out recently on a 24/8/6LX eight-wheeler which, running at just over 24 tons gross weight, was shown to have a good overall performance and exceptional fuel economy, more than 10 m.p.g. being obtained over a difficult test course which was completed at an average speed of 28-2 m.p.h. by observing a maximum speed of 40 m.p.h.

The test vehicle had the Gardner 6LX diesel engine, c4 driving through a David Brown 657 six-speed overdrivetop gearbox into a Moss 10-ton spiral-bevel axle. There are two other Seddon maximum-capacity eight-wheelers with the same basic chassis specification, one of these having a Gardner 6LW 112-b.h.p. engine, five-speed directtop gearbox and Eaton two-speed driving axle, whilst the other has the 6LX engine, six-speed box and Moss doubledrive rear bogie, this having spiral-bevel axles and a two-speed transfer gear giving ratios of 6-14 and 7-5 to 1.

All three models are offered with wheelbases of 14 ft. or 17 ft. 9 in., and quoted chassis-cab weights range from 5 ton 6 cwt. for the LW-engined 14-ft.-wheelbase model to 6 ton 11 cwt. for the double-drive machine in 17-ft. 9-in.-wheelbase form. With the standard gearing the LW model has a theoretical maximum speed of 38 m.p.h. and a peak gradient ability of 1 in 6-5. The equivalent figures for the single-driver with 6LX engine and the standard 614-to-1 axle are 44 m.p.h. and 1 in 5-2, whilst the double drive model has a maximum speed of 44 m.p.h. also and a gradient ability of 1 in 4-4.

Two-spring Bogie

The chassis tested was in perfectly standard trim, its specification including the latest version of the Seddon two-spring bogie, as exhibited at Earl's Court last year, eight-wheeled brakes actuated by a dual-circuit air-pressure system, power-assisted steering, 10-875 in. by 3-0 in. by 0.3125 in. chassis-frame side members and plastics-panelled cab, this being made by the newly formed Seddon coachbuilding company, Pennine Coachcraft Ltd., although the cab and the works in which it is manufactured are virtually unchanged. The standard tyres are 9-00-20 (12-ply), but the test machine was shod with Michelin " X " tyres of the same nominal size.

Complete with Pennine 24-ft. light-alloy platform body with headand tail-boards, the vehicle weighed 7 tons 7-5 cwt. ready for the road, the dry chassis-cab weight of this particular model being 6 tons 5 cwt. Equally distributed test blocks brought the gross weight up to 24 tons 1 cwt. with myself and Seddon's Frank Galbraith in the cab, the distribution being such that the rear-bogie tyres were each carrying slightly more than those of the front bogie.

It is interesting to compare the weight figures of this chassis with those of one of the original Seddon eightwheelers which I tested in November, 1958. This had the 6LX engine also, but the gearbox was a five-speed unit, the rear bogie had twin overhead-worm axles, and the brakes were Kirkstall cam units (on all wheels) with Clayton Dewandre piston-type actuators. The kerb weight of the DD8 chassis-cab was 7 tons 1.25 cwt., which is only 6.25 cwt. less than the kerb weight of the single-driver have just tested complete with body.

The braking tests revealed a slightly disappointing performance, attributable mainly to, system delay. Indeed, the figures obtained this time on a dry road were almost identical to those recorded in 1958 with the DDS on a wet road, suggesting that the braking system of the earlier chassis was not all that archaic after all, although in respect of life the extra 324 sq. in. of lining area of the later chassis could be an advantage. The eight-wheelet pulled up in a very steady fashion from both the test speeds, and the effectiveness of the rear-bogie suspension geometry was indicated by the complete absence of wheel locking. Hand-brake tests were not carried out, of course, as a multi-pull mechanism is fitted.

Better acceleration figures were obtained during this test when compared with the 1958 results, contributory reasons for this being a Tower final-drive ratio (6.14 to 1 compared with 5.6 to 1), slightly closer intermediate box ratios and the fact that the engine had covered over 4,000 miles before I started my tests, whereas the unit in the earlier vehicle had been considerably newer. I would have liked to have been able to take times up to 40 m.p.h., but there is not a long enough stretch of level road in the Oldham area for these to be carried out with a vehicle of this weight and acceleration characteristics, so I had to be content with figures up to 30 m.p.h. The smooth power delivery of the 6LX was particularly apparent during the directdrive runs, and the acceleration between 10 and 20 m.p.h was especially good.

As detailed in the data panel, four sets of fuel consump tion figures were taken over the usual none-too-easy 6-mile course on the Manchester side of Oldham, the chances of a clear run along this route being extremely slight as six sets of traffic lights and one busy roundabout have to be negotiated on each test. Two runs were made laden and unladen, one test in each case while observing a maximum speed of about 31 m.p.h., and the other while trying to keep the speed up to 40 rn.p.h.

A calibrated 1-gal. test tank was introduced into the fuel circuit to ensure maximum accuracy, and the laden figures obtained show the remarkable fuel economy of the Gardner c6 6LX engine in a vehicle of this weight, the gross ton-m.p.g. figures being first rate. Because the maximum road speed of the test vehicle was only 44 m.p.h. there was not a great deal of difference between the average speeds when making the two laden runs, as it was difficult to hold the speed at 40 m.p.h. for any length of time, but it will be noted that there is a more worth-while average-speed difference in the case of the two unladen runs, the fuel economy achieved during these two tests being highly commendable also.

There is no doubt that overall fuel costs with this 6LXengined eight-wheeler will be as low as can reasonably be expected for any vehicle of this weight i and this s, of course, the biggest attraction of the 6LX for heavy-goods chassis. !find it difficult to believe that the Seddon 24/8/6LW model with the 6LW engine and two-speed axle will be able to match the economy of the type I tested, and even if it did the difference would have to be very great to offset the reduction in road performance and the various other penalties associated with very low powerto-weight ratio.

Buckstones Road, Shaw, was used for the gradient-performance trials, this hill being 125-mile long and having an average gradient of 1 in 12. The ambient temperature was 9°C. (48°F.), and the engine-coolant temperature before making the ascent was 25-5°C. (78°F.), measured at the radiator header tank. The summit was reached 12-5 minutes after starting off, and most of the climb was spent in second gear at about 5 m.p.h.—at which road speed the engine is developing its maximum torque— although bottom gear had to be engaged twice for a total time of 1 minute 35 seconds, during which periods the road speed fen to 4 m.p.h. The final coolant temperature was 36,5°C. (98°F.), indicating very generous coolant capacity, particularly as the instrument-panel gauge suggested that the coolant temperature on the engine side of the thermostat had not risen at all during the climb.

Despite the different gearing, the climbing time with this vehicle was almost identical to that with the machine tested in 1958, although one difference occasioned by the ratio variations was that it was not necessary to use bottom gear with the earlier vehicle because the overall ratio in second Was just that little bit lower than the equivalent overall ratio of the current model: that the difference is of no significance is shown by the virtually identical overall climbing times..

Fade-resistance Check Fade resistance was checked by coasting the eight-wheeler down Buckstones Road, with the footbrake applied continuously for 4 minutes 20 seconds to keep the speed down to 20 m.p.h. At the bottom of the hill a full-pressure stop showed that the maximum efficiency had fallen from 60 per cent to 42 per cent which, despite the severity of the test, is to my mind a rather big drop—certainly for a vehicle with a lining area of 1,364 sq. in. The brakes on the driving axle were smoking profusely at the end of this test, whilst the front brakes did not appear to have got very hot at all, so one of the troubles might be that the rears are being expected to do a disproportionate amount of the work. The fade resistance with the 1958 eight-wheeler was absolutely firstclass, the maximum efficiency dropping by only 0135g. during the same sort of test on this hill.

Following the fade test, the eight-wheeler was returned up the hill and stopped on the 1-in-6-5 section, where the handbrake proved powerful enough to hold it despite the rear drums being still very hot. There was ample power for a bottom-gear restart, but driving-wheel spin could be induced. At this stage the value of the load-transfer cylinders was proved, because with the system in action there was no trace of wheel spin. The same held true when reverse restarts were made facing down the same slope.

These were the only occasions on which it really became necessary to use the load-transfer system; I did not engage the cylinders when making the brake tests as doing so would only have tended to increase the possibility of the trailing-axle wheels lifting, which can so easily occur with a conventional two-spring suspension.

Taking this Seddon eight-wheeler generally, its performance is entirely satisfactory, and drivers will find it pleasant to handle into the bargain, the only weak spot being the steering, which has an excessively large lock to the right and which, because of the high gearing possible when a servo is fitted as standard, is very direct, with only slight castor effect. With only 2-75 turns from lock to lock the question of steering heaviness in the event of servo failure arises also. Once used to it, the directness of steering can be an advantage, however, particularly when manceuvring in tight corners.

Chassis suspension was very good, although, despite the revised layout of the front-bogie springing, bad road surfaces still tended to be felt at the steering-wheel rim. The seats are comfortable too, so physical fatigue should not be a problem. Engine noise was on the high side, though, as the sheet-metal cowl is uninsulated. The gearbox was particularly sweet to use, and the clutch light to operate: the spread of ratios suits the engine's characteristics admirably, and the unit was always able to pull to its best advantage, although even so progress up hills could be painfully slow at times.

Brake-pedal action was fully progressive, and as a result there is little fear of over-zealous braking when unladen even though the pedal effort needed for normal retardation was light. The handbrake lever is well placed so far as reaching it is concerned, but its location tends to obstruct access to the driving seat. Generally the cab is good and very roomy, but criticisms include the rather confusing placing of the electrical switches and the central location of the instrument cluster: the dials would be much easier to read if they were immediately ahead of the driving seat.

All-round visibility given by the cab glazing and the large rear-view mirrors is very good, and a Triplex Zonetoughened windscreen panel is fitted on the right-hand side. Maintenance is about average for an eight-wheeled rigid, although various improvements have been made since my last test of a Seddon eight-wheeler. Engine accessibility is better on vehicles produced subsequent to the one just tested, as a new type of engine cowl has been developed which has two hinged sections on each side of the engine and gives clear access down to cab-floor level. Another good point is that the old type of spare-wheel carrier at the extreme end of the frame has been replaced by a more simple carrier which is far easier to get at and which is located immediately ahead of the off-side driving wheel.