Ways and Means of

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

LIGHTENING CHASSIS

IT is unnecessary to commence an article such as this by giving a long list of advantages to be obtained from the use of lightweight chassis in the transport industry, for every operator—large or Small—knows well that every pound in weight saved in the chassis means an extra pound available for freight.

Radical Changes Impracticable.

It is obvious that certain factors must be taken for granted. A modern chassis is merely built up of essential components, so it is unreasonable to expect that any major item can be eliminated. Thus, radical changes in design are not indicated, the whole question turning around the problem of the careful design of individual components, the matter of weight being kept to the forefront.

Probably the greatest scope of all is offered in the design of the chassis frame itself, and one often 'wonders whether the accepted practice of building a chassis separately from the body is really necessary. The frame of any vehicle, no matter whether it be a 10-cwt, four-wheeled van or a 10ton six-wheeled lorry, is nowadays considered to be sufficiently stiff to withstand the ravages caused by carrying an unevenly distributed load. Indeed, many chassis are tested by manufacturers with a concentrated test freight, which seems to prove that the body or platform adds little strength to the main frame (or, if it does so, such strength is redundant).

Nevertheless, we find that a platform lorry, for example, may have as many as 15 or 16 crossbearers cut from oak (with a section of 6 ins. by 2 ins, at least, on a large B26 chassis) set below the floor. This represents a considerable weight and, if a chassis could be produced with platform bearers built unitwise, as it were, the strength of the assembly could be made just as great as in contemporary design, but much lighter.

It is, of course, well known that the strength of a beam varies as the square of its depth, so deep side-members made of thin-gauge material are indicated. Such a structure, however, if planned on everyday lines, may be criticized on the score of " weaving " possibilities, but by introducing a large number of cross-ties, shaped so as to form the bearers for the platform, all such tendency could be cut out.

A Framework of Great Strength.

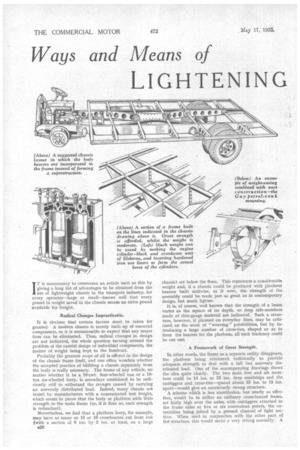

In other words, the frame as a separate entity disappears, the platform being reinforced sufficiently to provide adequate strength to deal with a full but unevenly distributed load. One of the accompanying drawings shows the idea quite clearly. The two main fore and aft members could be 14 ins. or 15 ins, deep amidships and the outriggers and cross-ties—spaced about 15 ins. to 18 ins. apart—would give an enormously strong structure.

A scheme which is less unorthodox, but nearly as effective, would be to utilize an ordinary cross-braced frame, set fairly high over the axles, with outriggers attached to the frame sides at five or six convenient points, the extremities being joined by a pressed channel of light seetioa. When used in conjuncton with the other .part of the structure, this would make a very strong assembly: A

point worth bearing in mind is that these outriggers and cross-pressings could be of similar form, so that the cost of production would be low. At all points where spring attachments are made, reinforcement would be simple.

This brings us to another factor—suspension. There is no doubt that the present arrangement of semi-elliptic road springs makes the axle assemblies very heavy. The mains excuse for continuing such systems is that they function quite well. It is the opinion of the writer, however, that we are on the eve of important developments in he Matter of springing.

Alternative Suspension Systems.

Already, chassis fitted with air cylinders instead of springs have been in production, whilst rubber suspension, as used cm the Scammell new-type machines, is also a development which will be watched with considerable interest.

In one application, which is to the four-wheeled bogie of a rigid six-wheeler, a balance beam is pivoted at its mid-point below the bogie cross-member. Its front end is attached by a ball-jointed link to a bracket at the back of the driving axle and its rear end to the lower plunger plate of the cushioning columns. These consist of a number of rubber discs placed one upon the other in two piles. An upper plate carries the two plungers which move axially in the columns and the rubber clists are compressed between the upper plate and the base plate. We illustrate another application to a pair of trailing axles. The rubber columns act in a similar manner to springs, hut afford an elasticity devoid of reciprocal action and they are, moreover, of very light weight.

In considering engine design one has perforce to adhere to accepted practice so far as dimensional considerations are concerned, because the internal-combustion engine, as a type, is now in a highly developed state, and the power

to-piston-swept-volume ratio is,generally speaking, high. Thus, any weight reduction has to take the form of a revision of material specification.

The use of liners for cylinder bores has become almost universal in high-grade products, and it seems a natural development for the cylinder block and the upper half of the crankcase to be made in a unit casting of light alloy with wet liners for the bores. By utilizing such a deep structure as that afforded by unit construction, immense strength can be achieved with quite moderate weight, especially if such an alloy as Elektron be employed.

Lightening Engine Parts.

Bearing housings and caps for the crankshaft journals can be of steel or bronze without any material addition to the weight, but with great advantage, so far as strength to resist the repeated reversal of stress obtaining in a reciprocating engine is concerned. For the engine feet, deep moulded arms of light alloy, attached to, or formed unitwise with the crankcase, are quite safe from a strength point of view, especially if a resilient material such as rubber be interposed between the arms and the frame.

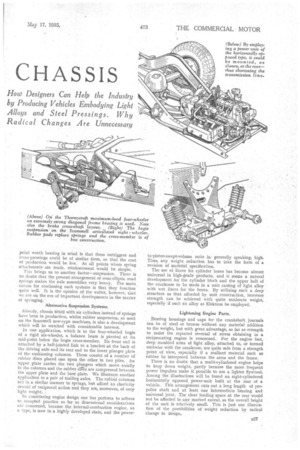

There is no doubt that a multi-cylindered engine helps to keep down weight, partly because the more frequent power impulses make it possible to use a lighter flywheel. Among the illustrations will be found an eight-cylindered horizontally opposed power-unit built at the rear of a vehicle. This arrangement cuts out a long length of propeller shaft and at least one intermediate bearing and universal joint. The clear loading space at the rear would not be affected to any marked extent, as the overall height of the unit is relatively small. This is just one illustration of the possibilities of weight reduction by radical change in design.