ROADSIDE AND GARAGE.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

A Page for Drivers, Mechanics and Foremen.

When Fitting Main Bearings.

The sender of the following communication has bees awarded the extra payment of 5s. this week. '

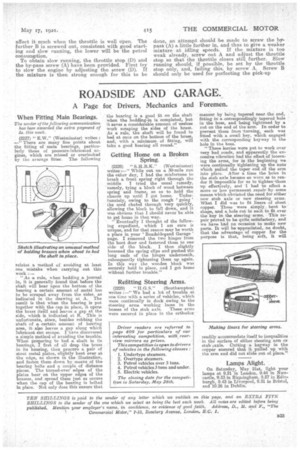

(2227) " E.W." (Westminster) writes : "There are many fine points about the fitting of main bearings, particularly those of pressure-lubricated engines, which are missed or overlooked by the average fitter. The following

relates a method of avoiding at least one mistake when carrying out this work :—

"Ac a rule, when bedding a journal in, it is generally found that before the shaft will bear upon the bottom of the bearing a certain amount of metal has to be scraped away from the sides, as indicated in the drawing at A. The result is that when the bearing is put together with the cap in place, it opens the brass itsQf and leaves a gap at the side, which is indicated at B. Thie is unfortunate, since, besides robbing the shaft of a certain amount of bearing area, it also leaves a gap along which lubricant an escape. I have discovered a simple method of avoiding the trouble. When preparing to bed a shaft in its bearings, I first of all drop the brass in its housing, then procure a pair of stout metal plates, slightly bent over at the edge, as shown in the illustration, and fasten them down by means of the bearing bolts and a couple of distance pieces. The turned-over edges of the plates bear on the upper edges) of the brasses, and spread them just as occurs when the cap of the bearing is bolted in place. Not only does this ensure that the bearing is a. good fit on the shaft when the bedding-in is completed, but it saves a considerable amount of useless work scraping the sides of the brass. As a rule, the shaft will be found to bed at once on the bottom of the brass, and, with a minimum of fitting, will take a good bearing all round."

Getting Home on a Broken Spring.

(2228) " S.11 .B.K." (Westminster) writes :—" While out on a 30-mile run the ether day, I had the misfortune to break a front spring right through the middle I tried the usual remedy, namely, tying a block of wood between spring and frame, so es to hold the chassis up until I got home. Unfortunately, owing to the rough ' going ' the cord chafed through very quickly, allowing the block to fall down, and it was obvious that I shotad never be able to get home in that way. " Eventually I thought of the following expedient, which I am sure is unique, and for that reason may be worth a place in your Roadsidetand Garage' page. I removed the two hinges from the boot door and fastened them to one side of the block. I then slightly loosened the spring clips and pushed the long ends of the hinges underneath, subsequently tightening them up again. In this way the wooden block was securely held in place, and I got home without further trouble."

Refitting Steering Arms.

(2229) " . G. S. " (Southampton) writes :—" We had a lot of trouble at one time with a series of vehicles, which were continually in dock owing to the steering arm i s working loose n the bosses of the stub axle. These arms were secured in place in the orthodox

manner by being tapered near the end, fitting in a correspondingly tapered hole in the boss, and being tightened by a nut on the end of the arm. In order to prevent them from :turning, each was fitted with a small key, which engaged with the corresponding keyway in the hole in the boss.

"These lorries were put to work over very bad roads, and apparently the excessive vibration had the effect of loosening the arms, for in the beginning we were continually tightening up the nuts Which pulled the taper end of the arm into place. After a time the holes in the stub axle became so worn as to render it impossible for us to tighten -them up effectively, and I had to effect a more or less permanent repair by some means which obviated the need for either new stub axle or new steering arms. What I did was to fit liners of sheet copper. These were simply, bent to shape, and a. bole cut in each to fit over the key in the steering arms. This repair proved to be quite satisfactory, and we have had no occasion to make new parts. It will be appreciated, no doubt, that the advantage of copper for the purpose is that, being soft, it will

readily accommodate itself to inequalities in the surface of either steering arm or stub ?axle. Cutting a keyway in the copper ensured that it pulled up with the arm and did not slide out of place."

Lamps Alight.

On Saturday, May 21st, light your lamps at 9.21 in London, 9.44 in Newcastle, 9.33 in Birmingham, 9.57 in Edinburgh, 9.43 in Liverpool, 9.31 in Bristol, and 10.26 in Dublin.