Successful period of transition for MCW

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

Metro-Ca mmell Weymann is now well placed to capture an even more significant sector of the public bus market. Noel Millier looks at the background to the company's growth from bodybuilder to manufacturer

BEFORE the 1982 Motor Show independent coach operators in Britain could be forgiven for not thinking of Metro-Cammell Weymann when considering their vehicle acquisition plans. However, MCW stole that show with its Metroliner coaches and although this impetus was not maintained there have been significant orders for the new models.

The National Bus Company's order for 39 of the Metroliner three-axle double-deck coach changed most pundits' predictions on the size of the new market for this exciting but expensive category of coach.

The first of the 39, and the first of a repeat batch for the Scottish Bus Group, which has the first prototype, is now nearing completion and the imposing vehicles will become a familiar sight on our motorways this summer.

The Metro-Hi-Liner integral coach luanched at the end of last year has been fairly well re ceived, and like the normal height chassied Metroliner and the double-decker, is now available through coach dealer Stuart Johnson for the independent sector of the coach industry.

Initial impressions of the vehicle show that it is a high specification alternative to imported coaches offering the same standards of passenger comfort and performance.

It is in the double-deck market that MCW has long been established, first as a bodybuilder and later as a complete vehicle manufacturer in its own right. Its Metrobus decker launched in 1978 has successfully challenged Leyland products to gain significant shares of the public sector bus market, and despite the hard times facing this part of the bus operating industry, it is still finding new orders as well as significant repeat business.

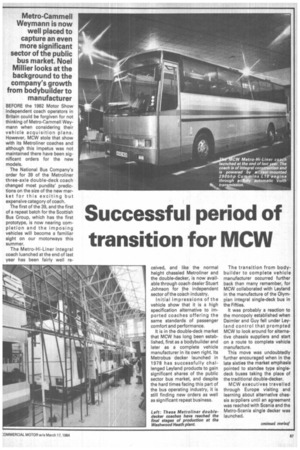

Left: These Metroliner doubledecker coaches have reached the final stages of production at the Washwood Heath plant.

The transition from bodybuilder to complete vehicle manufacturer occurred further back than many remember, for MCW collaborated with Leyland in the manufacture of the Olympian integral single-deck bus in the Fifties.

It was probably a reaction to the monopoly established when Daimler and Guy fell under Leyland control that prompted MCW to look around for alternative chassis suppliers and start on a route to complete vehicle manufacture.

This move was undoubtedly further encouraged when in the late sixties the market emphasis pointed to standee type singledeck buses taking the place of the traditional double-decker.

MCW executives travelled through Europe visiting and learning about alternative chassis suppliers until an agreement was reached with Scania and the Metro-Scania single decker was launched. By the early Seventies the scene changed dramatically and agreement was reached with trade unions for the one-manoperation of double-deck buses. Suddenly everyone wanted deckers and MCW reacted quickly to produce its Scaniabased Metropolitan.

The bus sold well despite the political problems associated with selling non-British-based products in a largely public sector market. At the time MCW was still bodying Leyland chassis including part of the large London Transport DMS Fleetline fleet.

Many operators turned to the Metropolitan to avoid Leyland's production difficulties, which at the time were disrupting delivery schedules.

New bus grant at this time kept the market buoyant although a general dissatisfaction with the performance of firstgeneration rear-engined deckers was causing MCW to join Leyland, Volvo, Dennis and Foden in a race to develop a new generation vehicle.

In many respects the Metropolitan was the forerunner of the new generation decker with its fully automatic gearbox and air suspension.

Its wider acceptance was in doubt though because of its foreign running units and the continued demand from the operators for Gardner-engined buses. Scania was not prepared to offer a Gardner option so MCW set about developing its own bus using experience gained from the Metropolitan.

Leyland's Titan prototype had been running for several years when the first Metrobus appeared on the scene in 1978. Although evolved with the aid of Metropolitan experience, it was in no way a Gardner-engined alternative.

The steel framed Metropolitan structure was replaced by a new aluminium structure, a new driveline was developed and the then-promising, now-proven Voith D851 transmission was adopted.

Buses were supplied to large fleet customers including London Transport, West Midlands Passenger Transport Executive and the China Motor Bus Company in Hong Kong.

Although the new generation had teething problems MCW gained a reputation for quick and decisive service response. Buses in the world's toughest proving ground — Hong Kong — quickly became among the most reliable.

Leyland misfortunes again aided Metrobus when production problems with the Titan caused LT to step up its Metrobus order and production rose to 20 units per week.

Today the Mark One Metrobus is still being delivered in large numbers to LT, which will soon be operating over 1,000 of the type.

For the rest of the world, Metrobus has been simplified with the Metrobus Mark Two which is less labour-intensive and easier to repair and build. Recent investment in manufacturing machine tools has enabled MCW to rationalise Metrobus production for this model.

Multi-function numerical control machines are used for the production of standard body parts, which are pre-punched for high precision and interchangeability.

The Mark Two is more efficient to produce, easier to repair and simpler to supply in kit form for assembly by export customers. MCW's success with the Metrobus has also required the setting up of a fully computerised parts supply and service back-up in Britain, which has already been proven and augurs well for meeting the needs of the coaching industry.

The company itself is part of the massive Laird group and although it is autonomous within the Group, MCW management have clear policy guidelines which include an insistence that bus and coach manufacture remains in the black. This requirement is reflected in its softlysoftly approach to the coach industry. Sales director Trevor Webster told me that he was happy for a slow sales build-up in an independent market.

MCW has the products and knows it can be competitive on price but it is not interested in diving into a price war or buying its way into the market. Stuart Johnson Ltd has the marketing and sales expertise to make a major impact on the marketplace.

I feel, therefore, that it is only a matter of time before MCW achieves this impact and becomes a major British challenger to the imported high specification coaches taking a share of the independent coach market.

Although the company does not manufacture major running units it does have flexibility, and its own research and development programme is run in co-operation with those of component manufacturers.

MCW has been the first major British bus manufacturer to realise the potential of the Cummins L10 engine, which is proving a suitable power unit basis for both stage carriage buses, and in its most powerful form, high-specification coaches.

Today MCW research engineers are looking at a large number of products including new types of buses and a replacement taxicab. The taxi project is at an advanced stage but will become the baby of a separate Laird company when it enters production.

The large MCW factory at Washwood Heath includes the railway rolling-stock workshops, although this too is controlled by a separate financial company within the group. Each activity is therefore insulated against major recession in a sister group.

Today, MCW as a bus manufacturer employs around 1,000 people and has the production capacity to produce 20 buses per week. Last year it produced around 750 units, including 375 chassis and bodies and 107 chassis, which gave it around 28 per cent of the public sector bus market. This year 34 per cent is well within its sights.