A New Down-draught Gas Producer of Belgian Design

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

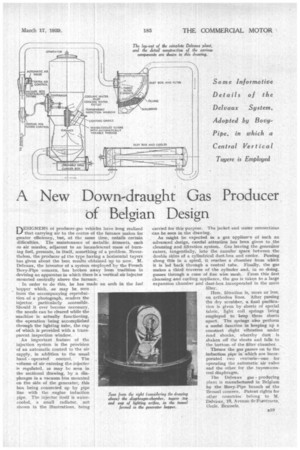

riESIGNERS of producer-gas vehicles have long realized LP that carrying air to the centre of the furnace snakes for greater efficiency, but, at the same time, entails certain difficulties. The maintenance of metallic fitments, such as air nozzles, adjacent to an incandescent mass of burning fuel, presents, in itself, something of a problem. Nevertheless, the producer of the type having a horizontal tuyere has given about the best results obtained up to now. Id. Delvaux, the inventor nf a system employed by the French Bovy-Pipe concern, has broken away from tradition in devising an apparatus in which there is a vertical air injector mounted centrally above the furnace.

In order to do this, he has made an arch in the fuel hopper which, as may be seen from the accompanying reproduction of a photograph, renders the injector particularly accessible. Should it ever become necessary, the nozzle can be cleared while the machine is actually functioning, the operation being accomplished through the lighting tube, the cap of which is provided with a transparent inspection window.

An important feature of the injection system is the provision of an automatic control to the air supply, in addition to the usual hand operated control. The volume of air entering the injector is regulated, as may be seen in the sectional drawing, by a diaphragm in a vacuum box mounted on the side of the generator, this box being connected up by pipe line with the engine induction pipe. The injector itself is watercooled, a small radiator, not shown in the illustrations, being carried for purpose. The jacket and water connections can be seen in the din.wing.

As nii.ght be expected in a gas applianre Of such an advanced design, careful attention has been given to the cleansing and filtration system. -Gas leaving the generator enters, tangentially, into the annular space between the double skins of a cylindrical dust:box and cooler. Pasting along this in a spiral, it 'reaches a chamber from which it is led back through a central tube. Finally, the gas makes a third traverse of the cylinder .and„ in so doing, passes through :a, cone of fine wire mesh. From this first cleansing and cooling appliance, the gas is taken to -a large expansion chamber and dust-box incorporated in the main filter.

Here, filtration ia, more or less, on orthodox lines. After pasSing

the dry scrubber, final purification is given by sheets of special fabric, light coil springs being employed to keep these sheets .apart. The springs also perform a useful function in keeping up a -constant slight vibration under road shocks, whereby dust is shaken off the sheets and falls to the bottom of the filter chamber.

Thence the gas passes on to the induction pipe in which are incorporated two ventmis—one for operating the autorfiatic air valve and the other. for the tuyere-control diaphragm.

The Delvaux gas producing plant is manufactured in Belgium by the posy-Pipe branch of the Brossel concern, Patent rights for other countries belong to M. Delvaux, 16, Avenue de Foestraets, Uccle, Brussels.