A Power driven Movable Floor

Page 107

If you've noticed an error in this article please click here to report it so we can fix it.

Full Technical Description of the Enginedriven Steel-slat Floor and All-metal Body Produced by a Well-known London Concern

GENERAL development of interest in movable floors for lorries seems to be taking place. leor more than a year Transport Engineering, Ltd., at its extensive works at 561, Old Kent Road, London, S.E.1, has been engaged on the production of an all-metal type of moving floor driven by a power take-off from the gearbox. The floor was shown at the British Industries Fair, at Birmingham, and

referred to in our report thereon; at the Fair it was engaged in taking on and discharging about 50 2-ton loads every day.

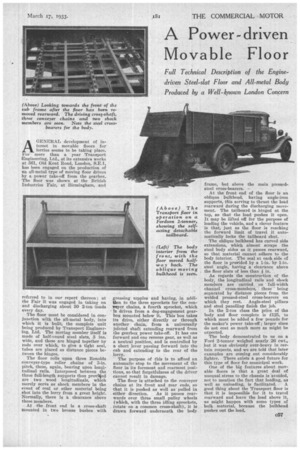

The floor must be considered in conjunction with the all-metal body, into which it is built, the complete unit being produced by Transport Engineering, Ltd. The moving member itself is made of half-tound steel slats, 3 ins. wide, and these are hinged together by rods over which, to give a tight seal, tubes are placed as distance pieces between the hinges.

The floor rolls upon three Renolds conveyer-type roller chains of 3-in. Ditch, these, again, bearing upon longitudinal rails. Interposed between the three full-length supports thus provled are two wood longitudinals, which merely serve as shock members in the event of coal or other material being shot into the lorry from a great height-. Normally, there is a clearance above these members.

At the front end is a cross-shaft mounted in two bronze bushes with

greasing nipples and having, in addition to the three sprockets for the conToyer chains, a fourth sprocket, which Is driven from a dog-engagement gearbox mounted below it. This box takes its drive, either directly or through another chain, from a universally jointed shaft extending rearward front the gearbox power take-off. It has one forward and one reverse gear, as well as a neutral position, and is controlled by a short lever passing forward into the cab and extending to the rear of the lorry.

The purpose of this is to afford an automatic stop to the movement of the floor in its foremost and rearmost positions, so that forgetfulness of the driver cannot result in damage.

The floor is attached to the conveyer chains at its front and rear ends, so that it is pushed as well as pulled in

either direction. As it passes rearwards over three small pulley wheels (which, with the three idling sprockets, rotate on a common cross-shaft), it is drawn forward underneath the body

frame, but above the main pressedsteel cross-bearers.

At the front end of the floor is an oblique bulkhead, having angle-iron supports, this serving to thrust the load rearward during the discharging movement. The tailboard is hinged at the top, so that the load pushes it open. It may be lifted off for the purpose of loading the vehicle, and a clever feature is that, just as the floor is reaching the forward limit of travel It automatically locks the tailboard shut.

The oblique bulkhead has curved side extensions, which almost scrape the steel body sides as it passes rearward, so that material cannot adhere to the body interior. The seal at each side of the floor is provided by a 1-in. by 1-in. steel angle, having a clearance above the floor slats of less than it in.

As regards the construction of the body, the longitudinal rails and shock members are carried on full-width channel eross-members, these ' being separated by distance pieces from the welded pressed-steel cross-bearers on which they rest. Angle-steel pillars and steel panelling finish the job.

In the 2-ton class the price of the body and floor complete is £125, CO which must be added a few pounds for the maker's power take-off ; larger sizes do not cost so much more as might be expected.

The body demonstrated to us on a Ford 2-tanner weighed nearly 26 cwt., but it was obviously over-heavy in certain respects, and we are told that later examples are coming out considerably lighter. There exists a good future for this type of floor for municipal work.

One of the big features about movable floors is that a great deal of unequal stress to the chassis is 'avoided, not to mention the fact that loading, as well as unloading, is facilitated. A good thing about the Transport floor is that it is impossible for it to travel rearward and leave the load above it, as might happen with some types of bulk material, because the bulkhead pushes' out the load.