High-capacity Demountable Skip Equipment

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

DRODUCED by Toussaint and Hess,

of Dusseldorf, Germany, and imported to this country by lderriworth (Engineering) Ltd., Kent, Teha selfdemounting-skip equipment is being employed by Tidiways Ltd., Coventry, under contract to Coventry Corporation for the collection of building nibble, hardcore and boiler waste. The company plans to extend the service, according to demand, to cater for a wide field of industrial applications which could include the carriage of sand and gravel, scrap metal, chemicals, machines and so on.

Tidiways is a joint enterprise of Morton's (Coventry) Ltd. and the Coventry Sand and Gravel Co. Ltd., which was initiated in January to provide a refuse-disposal container service. Two Powell Duffryn Dempster Dumpster Bedford-based vehicles are employed on this project with 50 containers, the decisive factor in the use of Teha equipment for the new venture being the greater lifting capacity of the equipment, which is available with payload ratings of 4 to 12 tons.

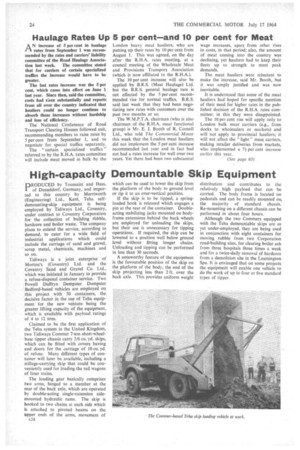

Claimed to be the first application of the Teha system in the United Kingdom, two Tidiways Commer 7-ton short-wheelbase tipper chassis carry 5/6 cu. yd. skips, which can be fitted with covers having end doors for the carriage of 10 cu. yd. of refuse. Many different types of container will later be available, including a stillage-carrying skip that could be conveniently used for loading the rail wagons of liner trains.

The loading gear basically comprises two arms, hinged to a member at the rear of the back axle, which are operated by double-acting single-extension sidemounted hydraulic rams. The skip is hooked to two chains at each side which is attached to pivoted beams on the upper ends of the arms, movement of A24

which can be used to lower the skip from the platform of the body to ground level or tip it to an over-vertical position.

If the skip is to be tipped, a springloaded hook is released which engages a pin at the rear of the container. Doubleacting stabilizing jacks mounted on bodyframe extensions behind the back wheels are employed for unloading the skips, but their use is unnecessary for tipping operations. If required, the skip can be lowered to a position well below ground level without fitting longer chains. Unloading and tipping can be performed in less than 30 seconds.

A noteworthy feature of the equipment is the favourable position of the skip on the platform of the body, the end of the skip projecting less than 2 ft. over the back axle. This provides uniform weight

distribution and contributes to the relatively high payload that can be carried. The body frame is located on pedestals and can be readily mounted or the majority of standard chassis. Re-mounting on a different chassis can be performed in about four hours.

Although the two Commers equipped with the Teha demountable skips are as yet under-employed, they are being used in conjunction with eight containers for moving rubble from two Corporation road-building sites, for clearing boiler ash from three hospitals three times a week and for a twice-daily removal of hardcore from a demolition site in the Leamington Spa. It is envisaged that on some projects the equipment will enable one vehicle to do the work of up to four or five standard types of tipper.