COOLING THE OIL TO EGUARD THE BEARINGS.

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

FIFTEEN years ago any engineer responsible for the design of commercial vehicles would probably have stated, if asked, that in his opinion, big-end troubles had been fully and finally overcome; now the whole subject is being reopened owing to the particularly onerous conditions imposed by fast, long-distance coach services and the fact that for such work engines of the six-cylinder type are commonly employed, which, owing to their characteristic of excellent mechanical balance, can be run up to very high rates of r.p.m. without giving visible signs of distress.

On the long-distance services which are now becoming so common—many of them connecting towns situated several hundreds of miles apart—the schedules demand a high average speed, so that the engine is being run for most of the time at full throttle and high revs. Furthermore, in order to keep up the average any good driver will tend to make full use of the gearbox, witirthe result that long hills are climbed in third or second speeds with the unfortunate power unit tearing away at 3,500 r.p.m." or more.

These two factors—high revs, and prolonged fullthrottle running—are apt to reduce the factor of safety on the big-end bearings almost to vanishing point. For other vital parts of the chassis no designer would dream of permitting a factor of less than about five to one, i.e., no part carries more than one-fifth of the maximum load which it can be expected to stand without failure. On the big-ends, however, of many of our modern high speed engines the ratio is apt to become unity, with complete failure only very narrowly averted.

In the first place, it must be understood that the higher the speed of the crankshaft the greater is the load thrown on the big-ends by inertia of the reciprocating parts and centrifugal force of the rotating parts, and this load becomes very much more important than that caused by the explosion of the mixture.

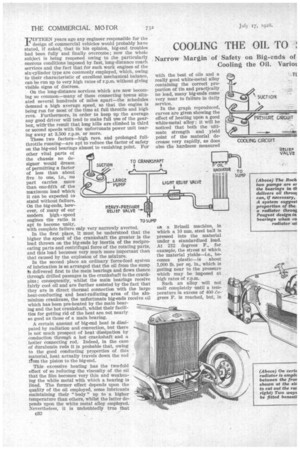

In the second place an ordinary force-feed system of lubrication is so arranged that the oil from the sump Ps delivered first to the main bearings and Bows thence through drilled passages in the crankshaft to the crankpins ; consequently, whilst the main bearings receive fairly cool oil and are further assisted by the fact that they are in direct thermal connection with the large heat-conducting and heat-radiating area of the aluminium crankcase, the unfortunate big-ends receive nil which has been pre-heated by the main bearing and the hot crankShaft, whilst their facilities for getting rid of the heat are not nearly so good as those of a main bearing.

TO

TO CRANKSHAFT HEAVY-PRESSURE RELIEF VALVE --1"

LARGE PUMP

• A certain amount of big-end heat is dissipated by radiation and convection, but there is not much prospect of heat -dissipation by conduction through a hot crankshaft and a hotter connecting rod. Indeed, in the case of duralumin rods it is probable that, owing to the good conducting properties of this material, heat actually travels down the rod ftom the piston to the big-end.

This excessive heating has the two-fold effect of so reducing the viscosity of the oil that the film becomes very thin and weakening the white metal with which a bearing is lined. The former effect depends upon the quality of the oil employed, some lubricants maintaining their " body " up to a higher temperature than others, whilst the latter depends upon the white metal alloy employed. Nevertheless, it is undoubtedly true that with the best of oils and a really good white-metal alloy containing the correct proportion of tin and practically no lead, many big-ends come very near to failure in daily service.

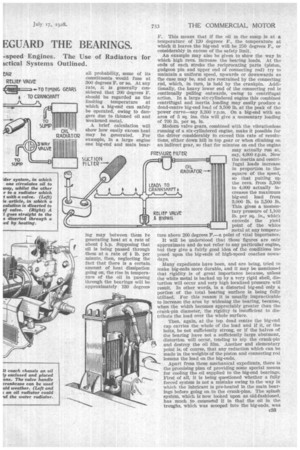

In the graph reproduced, curves are given showing the effect of heating upon a. good white-metal alloy ; it will be noticed that both the ultimate strength and yield point of the material decrease very rapidly, as does also the hardness measured 0,1 a Brinell machine, in which a 10 rum. steel ball is pressed into the material under a standardized load. At 212 degrees F., for example, the stress at which the material yields—i.e., becomes plastic—is about 1,000 lb. per sq. in„ which is getting near to the pressure which may be imposed at high rates of r.p.m.

Such an alloy will not men completely until a temperature in excess of 400 degrees F. Is reached, but, in all probability, some of its constituents would fuse at 300 degrees F. or so. At any rate, it is generally considered that 200 degrees F. should be regarded as the limiting temperature at which a big-end can safely be operated, owing to dangers due to thinned oil and weakened metal.

A brief calculation will show how easily excess heat may be generated. For example, in a large engine one big-end and main bear tug may between them te generating heat at a rate of about hp. Supposing that oil is being passed through them at a rate of lb. per minute, then, neglecting the fact that there is a certain amount of heat dissipation going on, the rise in temperature of the oil In passing through the hearings will be approximately 130 degrees P. This means that if the oil in the sump is at a temperature of 120 degrees-• F., the temperature at which it leaves the big-end will be 250 degrees F., or considerably in excess of the safety limit.

An example may also be given to show the way in which high revs, increase the bearing loads. At the ends of each stroke the reciprocating parts (piston, gudgeon pin and upper end of connecting rod) try to maintain a uniform speed, upwards or downwards as the case may be, and are restrained by the connecting rod, which, in turn, is held by the crankpin. Additionally, the heavy lower end of the connecting rod is continually pulling outwards, owing to centrifugal action. In a large six-cylindered engine this combined centrifugal and inertia loading may easily produce a dead-centre big-end load of 3,500 lb. at the peak of the power curve—say sgoo r.p.m. On a big-end with an area of 5 sq. ins, this will give a momentary loading of 700 lb. per sq. in.

Modern valve gears, combined with the vibrationless running of a six-eylindered engine, make it possible for the driver considerably to exceed this rate of revolutions, either down hill in top gear or when climbing on an indirect gear, so that for minutes on end the engine may actually run at, say, 4,000 r.p,m. Now the inertia and centrifugal loads increase in proportion to the square of the speed, so that putting up the revs. from 3,200 to 4,000 actually increases the maximum big-end load from 3,000 lb. to 5,500 lb. This gives a momentary pressure a 1,100 lb. per sq. in., which exceeds the yield point of the white metal at any temperature above 200 degrees F.—a point of vital importance:

It will be understood that these figures are only approximate and do not refer to any particular engine, but they give a fairly good idea of the conditions PRESSURE fILTER posed upon the big-ends of high-speed coaches nowadays.

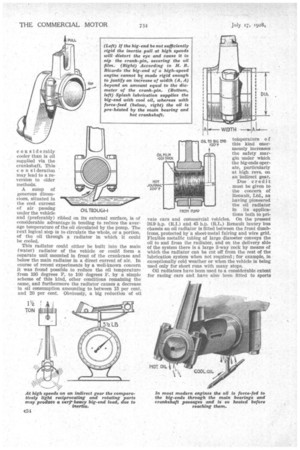

Many expedients have been, and are being, tried to make big-ends more durable, and it may be mentioned that rigidity is of great importance because, unless the white metal is backed up by a very rigid shell, distortion will occur and very high localized pressure will result. In other words, in a distorted big-end only a portion of the total bearing surface is being fully utilized. For this reason it is usually impracticable to increase the area by widening the bearing, because, when the width becomes appreciably greater than the crank-pin diameter, the rigidity is insufficient to distribute the load over the whole surface.

Then, again, at the top dead centre the big-end cap carries the whole of the load and if it, or the bolts, be not sufficiently strong, or if the halves of the bearing have not a sufficiently large abutment, distortion will occur, tending to nip the crank-pin and destroy the oil film. Another and elementary point is, of course, that any reduction which can be made in the weights of the piston and connecting rod lessens the load on the big-ends.

Apart from these mechanical expedients, there is the promising plan of providing some special means for cooling the oil supplied to the big-end bearings. First of all, it is being questioned whether a fully forced system is not a mistake owing to the way in which the lubricant is pre-heated in the main bearings before going on to the crank-pins. The splash system, which is now looked upon as old-fashioned, has much to commend it in that the oil in the troughs, which was scooped into the big-ends, was considerably cooler than is oil supplied via the crankshaft. Thisc o n si deration may lead to a reversion to older methods.

A suinp of generous dimensions, situated in the cool current of air passing under the vehicle and (preferably) ribbed on its external surface, is or considerable advantage in tending to reduce the average temperature of the oil circulated by the pump. The next logical step is to circulate the whole, or a portion, of the oil through a radiator in which it could be cooled.

This radiator could either be built into the main (water) radiator of the vehicle or could form a separate unit mounted in front of the crankcase and below the main radiator in a direct current of air. In course of recent experiments by a well-known concern it was found possible to reduce the oil temperature from 195 degrees P. to 100 degrees F. by a simple scheme of this kind, other conditions remaining the same, and furthermore the radiator causes a decrease in oil consumption amounting to between 15 per cent. and 20 per cent. Obviously, a big reduction of oil OIL TROUG1-1

tefup

era ure o f this kind enormously increases

• OLN MICK

(NI. FILM the safety mar

1;:( ate, particularly at high revs, on an indirect gear. 1107 Due credit zoo° rmust be given to

JOURNAL

the concern of Renault, Ltd., as • having .pioneered the oil radiator FROM PUMP in its applica tions both to private cars and commercial vehicles. On the present 26.9 lip. (R.I.) and 45 h.p. (R.L.) Renault luxury bus chassis an oil radiator is fitted between the front dumbirons, protected by a sheet-metal fairing and wire grid. Flexible metallic tubing of large diameter conveys the oil to and from the radiator, and on the delivery side of the system there is a large 3-way cock by means of which the radiator can be cut off from the rest of the lubrication system when not required ; for example, in exceptionally cold weather or when the vehicle is being used only for short runs with many stops.

Oil radiators have been used to a considerable extent for racing cars and have also been fitted to sports models sold to the general public by various concerns in addition to Renault, Ltd. Recently, two other French concerns have been experimenting in this direction, and we give diagrams showing the systems which they are trying.

In the Peugeot plan the whole of the oil, when hot, passes through the radiator and a filter on its way to the gallery pipe which supplies the crankshaft bearings. There is, however, a relief valve lecifling to a by-pass placed in parallel with the radia tor through which part of the oil is diverted when starting from cold, so safeguarding the supply to the crankshaft when the lubricant is sluggish. This relief valve is set to open at a pressure of 3 lb. per sq. in. In the Rochet-Schneider system two independent pumps are employed, one of which supplies the bearings in the ordinary way, whilst the other merely serves to draw oil from the sump and circulate it through a filter and radiator. Some of the oil is continually being cooled, which results in a much lower average temperature for the lubricant contained in the sump. Yet another plan is to allow oil from a relief valve to pass on through a radiator, using a pump of somewhat larger capacity than usual. In this way the oil delivered by the pump will have alternative paths, as it can pass either through the crankshaft and bearings or through the valve and oil radiator. Many makers of commercial vehicles are experimenting with various systems of oil-cooling, and it may be that oil radiators will eventually become accepted as part of the usual equipment of high-speed coaches. Certainly the additional complication involved is very small, whilst the advantages to be reaped are extremely important.