PLANT T1 THE LO, T KEEPS ) COOL

Page 46

Page 47

Page 48

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

By L. GRAHAM DAVIES Great Strides in the Design and Usi of Refrigerator Vehicles Have Beei Made in France and the United States Light Metals are Widely Used in Bod.

Construction

MARKED progress has been made during recent years, on both sides of the Atlantic, in the development of special vehicles for the transport of

perishable freight. On this side, France is probably ahead of most European countries in that particular field. It is interesting to compare the various systems employed in that country with those used in America. In both countries light alloys are employed in building double-walled insulated bodies to avoid adding much to the unladen weight. .

Refrigeration of road vehicles has been taken seriously in France for many years and is regarded as a most important link in the " chaine frigorifique " (the means for maintaining foodstuffs and perishable goods at a low temperature from the production stage to the time of delivery to consumers). So long as loading and unloading and the transfer to refrigerators are conducted rapidly, there should be no break in this chain.

Vehicles employed may be grouped in three categories—the Isotherme, in which the body has iv) actual cooling system, but is provided with efficient neat insulation;, the Refrigerant, employing ordinary water-ice or carbonic-acid "dry ice" for cooling purposes, and the Frigorifique. which carries a complete refrigerating plant, operated by an auxiliary engine.

The Isotherrne is used for urban deliveries, with loads of 20 cwt. to 35 cwt., or for relatively short runs with loads up to about 41 tons. The second type is intended for vehicles with the same operational range, carrying useful loads which vary from 1 ton to 71 tons on urban work and 3 tons to 71 tons on short road journeys. The Refrigerant, carrying an independent refrigerating plant, includes large vehicles, such as 12-ton articulated outfits engaged on long-distance transport.

Various insulating materials are used between the inner and outer skins of the bodies, such as glass wool, Iporka (a by-product of the manufacture of synthetic MI resins), rubber sponge, or Isoflex. The last mentioned has achieved great success; it is made from corrugated sheets of cellulose acetate and weighs only 12 oz. per cubic ft. Unlike glass wool and Iporka, it is non-hygroscopic and has insulating characteristics equal to those of cork.

Although excellent in many ways, cork cannot normally be employed economically in road vehicles on account of its density. It weighs 9 lb. per cubic ft. Alfol, already well known in England, has been employed in France with success by 'shipbuilders, and is now under test

in road vehicles. It is made of extremely thin sheets of aluminium foil and weighs only 3 oz. per cubic ft.

The first necessity in an insulated van body is that it shall be watertight and airtight, on account of the great difference between hygrometric tensions existing inside and outside the body. These may vary between —20 degrees C. inside the van and +30 degrees C. outside.

Moreover, bodies must be designed to avoid points of thermal leakage between inner and outer skins, particularly as metal bodies are now popular. Metal distance pieces between inner and outer panelling are liable to act as conductors.

French insulated van bodies are constructed in various ways. The simplest form consists of an ordinary van body with metal frame, to which the outer panelling is attached. Wood distance pieces are then fitted to give the required space for insulating material, and the inner panelling is fitted with the aid of metal distance pieces.

A better solution of the problem. currently employed by French coachbuilders, is to construct a body frame with double walls and roof, all frame members being of wood: Interior and exterior panelling is carried out in Duralinox sheet and the results obtained

are usually satisfactory. The main disadvantage attaching to this form of construction is weight.

Light-alloy refrigerator bodies are now being built on more scientific lines, particularly those on large vehicles carrying an independent refrigeration plant. Good examples of these have recently been added to the transport fleet of the Compagnie des Entrepots et Gares. Frigorifiques, of Paris, the work being carried out by the Ste des Prototypes de Carrosseries Legeres, in collaboration with engineers of the Cie. des Entrepots et Gares Frigorifiques. An article on the work of the Societe des Prototypes appeared in "The Commercial Motor " on November 14, 1947.

. For these types, one of which is based on a Panhard " 5-ton chassis and the other on a Coder I2-ton semitrailer, hauled by a S.O.fv1.U.A. tractor, two completely independent body frames are constructed, one within the other. The inner frame, which takes all the load stresses when travelling, is built up from robust, lightalloy extrusions, whilst the outer one, also in tight alloy, is of much lighter design, its function being mainly protective. When mounting the inner body frame, wood bearers, largely cut away to reduce weight, are placed on the chassis side-members before the channel-section alloy cross-members are fixed in position. The cross-members are arranged in pairs, back to back, with glass-wool insulation between them. Side pillars are jointed to the ends of these cross-members, the pillars and the roof ribs with which they connect at the top, being made from light-alloy extrusions. Interior panelling is Duralinox.

For the exterior, protective sheet steel extensions are electrically welded to the chassis side-members and to these is attached a band of pressed duralumin channel, upon which are assembled the frame members. Only half the number of side pillars and other members used in the interior frame is employed for the external one. The frame-members are, moreover, arranged in such a manner that no exterior member is opposite an internal member.

Ample Insulation Space

A minimum distance of 41 ins, is maintained every: where between internal and external panelling. There is a central sheet of insulating material, 21 ins, thick, between the two shells. Insulation beneath the floor comprises two layers of Isoflex, of which the lower one is cut only by transverse body-members and, even in this instance, only at their extreme ends.

Access to the internal body is obtained at the rear, by insulated double doors, 61 ins, thick, outside which is another pair of doors, non-insulated, in the exterior shell. The interior of the van is well ribbed with lightalloy channel to ensure free air circulation around the goods carried, which can in no circumstances touch the walls or floor surface.

The refrigerating plant is walled-in at the forward end of the van body. Two ventilating fans are mounted high. up. A S.A.T.A.M. group, powered by a 500 c.c petrol engine, drives a compressor and the ventilating fans receive their current directly from the dynamo.

The Coder 12-ton semi-trailer is designed on the same lines as the vehicle just described, but the refrigeration plant used is naturally larger. A S.A.T.A.M. threecylindered compressor is driven by a Simca-Huit petrol engine, the power unit used in the French version of a small Fiat car.

American Practice

In America, insulated van bodies, with cooling by "dry ice" or ordinary water ice, are widely used, but, as in France, the system of mounting a complete refrigerating plant on the vehicle is making rapid headway for relatively long-distance work.

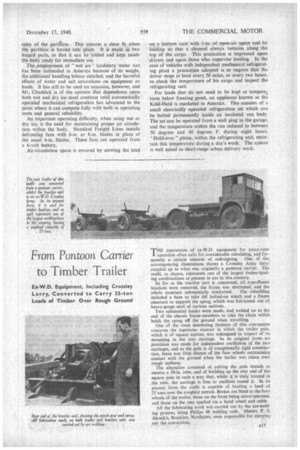

There are various proprietary makes of independent refrigerating equipment, notably Thermo-King, Trailair and a new one, Frostrode. The last-mentioned is a neat and compact unit, readily adaptable to existing insulated bodies. It includes an Onan 10 h.p. petrol engine, coupled to a six-cylinfiered compressor, and is designed for mounting high up on the front of a semi-trailer.

Although the complete unit weighs less than 71 cwt., it is capable of producing 24,000 B.T.U. per hour, or 2 tons of ice every 24 hours. All instruments and controls for the set are located on a hinged panel outside the van body. Apart from the usual instruments, these include high and low-pressure gauges for the Freon refrigerant employed.

Many point's in the design are aimed at reducing risks of servicing trouble on the road. The built-in 250-watt starter-generator, the axial-flow condenser fan, the condenser fan (1,500 cubic ft. per minute) and pulleys for the triple V-belt compressor drive are all in line with the engine crankshaft, fan-shaft extensions being mounted in self-aligning bearines.

B14 When used as a heating unit, the Frostrode equipment can maintain any desired temperature within the van, up to 70 degrees F., provided that the outside-inside temperature differential is not too great. To operate this unit, it is merely necessary for the driver to set the cooling or heating thermostat to the desited temperature, select the cycle required (cooling or heating) and turn the ignition switch, which also controls the starterdynamo. From that point, operation is entirely automatic.

An article in our American contemporary, "Commercial Car Journal," for June last, by Mr. H. F. Chaddick, president of Standard Freight Lines Inc., gives a good idea of present-day road-transport refrigeration practice in the United States. Standard Freight Lines operates 300 insulated tractor-trailer units, of which 15 are equipped with independent refrigerating plant and the rest employ "dry ice" or brine.

Of 50 vans operated by an affiliated concern, the American Transportation Co., 25 have insulated bodies and several are fitted with refrigerating plant. Local equipment in Chicago also includes four units designed for a collection and delivery service in connection with Chicago Consolidated Air Freight..

Temperature Below Freezing

These were first used in late autumn, 1946, and the immediate need then was to fit them with special heating units, to protect valuable air arrivals of delicate flowers from California and Florida. In recent years there has been an increase in the road haulage of meat and general lines of frozen foods, which require temperatures below freezing point. Under normal conditions, Standard Freight Lines is able to maintain temperatures of 30-20 degrees F. with "dry ice," or 15-10 degrees F. with the use of mechanical refrigerating sets.

Mr. Chaddick states that refrigeration has rarely failed on the road through delays in obtaining dry ice," or, in the case of other vehicles, from a temporary breakdown of the mechanical equipment. Far more serious troubles have arisen through carrying perishable loads which were thought to have been previously maintained at low temperatures, but, in fact, had not.

Heating protection for perishable air freight carried by road in cold weather is needed in the Chicago area during six, or even eight, months of the year. The unit employed is an adaptation of a petrol-engined automatically regulated mechanical heater, developed during the war for defrosting and starting aircraft. It is now obtainable from the Stewart-Warner Corporation.

Heating for Perishables

For heating the 26-ft. trailer used by Standard Freight Lines, the unit is mounted inside the trailer at the top of the front panel, and heat is released into a flattened funnel-like duct which broadens out to about half the width of the trailer body. The opening is arranged amidships, so that heat diffuses both ways.

One of the company's developments, which has been in use for the past three years, is a folding partition made to fit inside trailer bodies for the handling of part loads needing refrigeration. These separate the cold load from additional loads not needing refrigeration. The non-refrigerated goods are stowed in the forward part of the body, and the partition is fitted, leaving the remaining space for perishable goods. These are cooled by "dry ice" or brine-solution drums.

The partition is constructed from two sheets of light veneer board, separated by 2-in, distance pieces. Long strips of sponge rubber are inserted all round the edge. and the rubber extends 1 in. outwards along all four sides of the partition. This ensures a close fit when fill partition is forced into place. It is made in two hinged parts, so that it can be folded and kept inside the body ready for immediate use.

The ,employment of wet ice" (ordinary water ice) has been outmoded in America because of its weight, the additional handling labour entailed, and the harmful effects of water and salt saturations on equipment or loads. It has still to be used on occasion, however, and Mr. Chaddick is of the opinion that dependence upon both wet and dry ice must continue until. automatically operated mechanical refrigeration has advanced to the point where it can compete fully with both in operating costs and general reliability.

An important operating difficulty, when using we or dry ice, is the need for maintaining proper air circulation within the body. Standard Freight Lines installs defrosting fans with 6-in. or 8-in, blades in place of the usual 4-in. blades. These fans are operated from a 6-volt battery.

Air-circulation space is ensured by stowing the load

on a bottom rack with 1-in, of open-air space and by loading so that a channel always remains along the top of the cargo. This precaution is impressed upon drivers and upon those who supervise loading. In the case of vehicles with independent mechanical refrigerating plant a precaution adopted is to require that the driver stops at least every 50 miles, or every two hours. to check the temperature of his cargo and inspect the refrigerating unit.

For loads that do not need to be kept at tempera; tures below freezing point, an appliance known as the Kold-Hold is marketed in America. This consists of a small electrically operated refrigeration set which can be bolted permanently inside an insulated van body. The set can be operated from a wall plug in the garage, and the temperature within the van reduced to between 50 degrees and 40 degrees F. during night hours. "Hold-over" plates, within the refrigerating unit, maintain this temperature during a day's work. The system is well suited to short-range -urban delivery work.