A Successful Steam Generator.

Page 3

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

A Few Interesting Particulars Regarding Steam Generators in General, and the Lune Valley Boiler in Particular.

The chief source of weakness in steam vehicles undoubtedly is the steam generator. In the days when " pot" boiler was the only type of steam generator, the

the public looked on a steamdriven vehicle as being likely to" blow up " at any moment, and, although we can only recall one such accident (Russell's boiler which, in 1834, ex_ ploded as the direct result of an axle breaking, due to the state of the road between Glasgow and Paisley), the idea dies hard. In the hands of a careful driver, the " pot " boiler, or, rather, its later models, which embody either fire tubes or water tubes, will give excellent results. Its chief objection is the need for constant attention to the level of the water ; if the water level falls below a known safe limit, leaky tubes will be the inevitable result. The "flash" type of generator, which was largely employed by Serpollet and which is still being used by a few makers, is free, to a certain extent, from the objections that may be raised against the " pot " variety, but it has absolutely no capacity for the stor:ee of 'team with which to meet the sudden demands for power at such times as when starting with full load, or climbing a steep hill. With this type of steam generator, there is no chance of an explosion. The worst that can happen is a split tube, but this occurrence, however, beyond the temporary disablement of the machine, will do no harm; neither does such a split tube place the life of the driver, or those of his passengers, in danger. The need for intricate fuel-regulating devices that are designed for the purpose of preventing the burning-out of any of the generator tubes,

but which rarely achieve the objects of the inventor, constitutes the most serious obstacle to the extensive employment of this class of steam generator for commercial motors.

In addition to the two distinct types of generators to which we have already referred, there is a type which combines the best points of both the " pot " and the " flash " types, with practically none of their faults. We refer to the Lune-Valley boiler, which is made by the Lune Valley Engineering Company, of Lan caster. This is a generator which has given a large degree of satisfaction on public-service vehicles in London, arid the fact that more than one manufacturing concern has practically copied the design is proof that there is merit therein. A representative of the Editorial staff of this journal recently visited the works at Lancaster, where he saw several of these boilers under construction, and the accompanying illustrations are from photographs which were taken on that occasion.

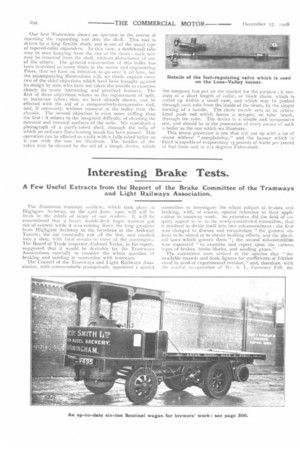

The boiler consists of a central shell, or drum, which is pressed out of one piece of steel plate, in much the same manner as a large explosive shell is made, and this drum is then turned and bored so that its thickness is in agreement with the required size. The drum isnext drilled for the various tubes and fittings, which must subsequently be "expanded in "to complete the generator. Each of the tubes consists of two or three coils of solid-drawn steel tube, the ends of which are expanded into holes in the drum, and these holes are so arranged that the flames from the burner are very completely broken up by the tubes. when in position, without any undue checking.

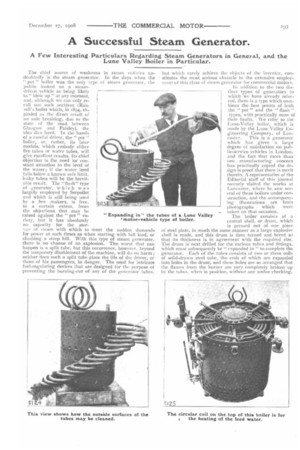

Our first illustration shows an operator in the course of inserting the expanding tool into the shell. This tool is driven by a long flexible shaft, and is one of the usual type of tapered-roller expanders. In this view, a double-coil tube may be seen hanging from the rim of the drum : each tufae may be removed from the shell, ‘yithout disturbance of au) of the others. The general construction of this boiler has been described so many times in the motor and engineering Press, that we have no intention to go over it all here, but the accompanying illustrations will, we think, explain away two of the chief objections which have been brought against its design by men who have not taken the trouble to examine closely its many interesting and practical features. The first of these objections relates to the replacement of split, or burnt-out tubes; this, we have already shown, can be effected with the aid of a comparatively-inexpensive tool, and, if necessary, without removal of the boiler from the chassis. The second objection is even more trifling than the first : it relates to the imagined difficulty of cleaning the external and internal surfaces of the coils. We reproduce a photograph of a partly-tubed shell, through the coils of which an ordinary flue-cleaning brush has been passed. This operation can be effected as easily with a fully-tubed boiler as it can with the one we illustrate. The insides of the tubes may be cleaned by the aid. of a simple device, which the company has put on the market for the purpose ; it consists of a short length of roller, or block chain, which is coiled up within a small case, and which may be pushed through each tube from the inside of the drum, by the simple turning of a handle. The chain merely acts as an articuktted push rod which forces a scraper, or tube brush, through the tube. The device is a simple and inexpensive one, and should be in the possession of every owner of such a boiler as the one which we illustrate.

This steam generator is one that will put up with a lot of abuse without " complaining," and the burner which is lined is capable of evaporating 15 pounds of water per pound of fuel from and at 212 degrees Fahrenheit.