Last time CM visited Stoke-based trailer and rigid bodywork designer

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

and manufacturer Don-Bur, a large part of its main site had been dug up in preparation bra new building.

Colin Barnett went back to see the results.

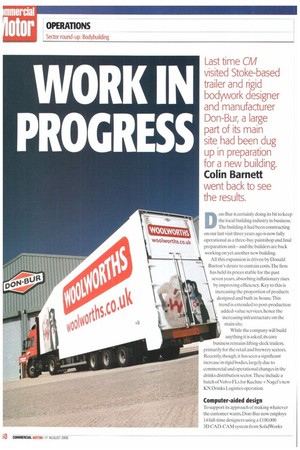

Don-Bur is certainly doing its bit to keep the local building industry in business. The building it had been constructing on our last visit three years ago is now fully operational as a three-bay paintshop and final preparation unit —and the builders are back working on yet another new building.

All this expansion is driven by Donald .Burton's desire to contain costs. The firm ..,\ has held its prices stable for the past seven years, absorbing inflationary rises by improving efficiency. Key to this is increasing the proportion of products designed and built in-house This trend is extended to post-production added-value services, hence the ., increasing infrastructure on the main site.

While the company will build anything it is asked, its core business remains lifting-deck trailers, primarily for the retail and brewery sectors. Recently, though, it has seen a significant increase in rigid bodies, largely due to commercial and operational changes in the drinks distribution sector. These include a batch of Volvo FLs for Kuehne + Nagel's new KN Drinks Logistics operation. Computer-aided design I o support its approach of making whatever the customer wants, Don-Bur now employs 14 full-tinne designers using a100,000 3D CAD-CAM system from Solid Works (www.solidworks.com). Drawing on an electronic inventory of components added to with each new project, the system is capable of creating a virtual prototype within half a day, including full stress analysis.

Another example of Don-Bur's use of technology is its cost-analysis package.This is an advanced spreadsheet incorporating all the factors involved in the construction and operation of a trailer, including a graphical illustration of loading patterns for specific pallet or roll-cage dimensions. It provides instant comparative running costs for various operating circumstances and designs. Aerodynamic sloping-roof trailers have been in vogue of late. hut Don-Bur has a realistic view of their feasihility.Vv'hile there is scope for the concept to create fuel savings, this has to be balanced against the loss of load volume.While operational feedback has seen companies such as Business Post reporting annual savings of about £6,500, this could turn into a loss of £9,000 when compared to full utilisation of the reduced space at the front of the trailer.

I watched the finishing touches being put to Don-Bur's new Eco-Stream demonstration trailer. It features outer panels made of Technolite,comprising an inner structure made of a lightweight aluminium honeycomb material with aluminium outer facings. which are used for aircraft flooring. Overall thickness is 20mm, with 2mm-thick outer skins, which compared with GRP saves aroundl ,000kg on a full-sized trailer albeit at a cost of about f2,00f).Technolite trailers are currently undergoing trials with Argos and John Lewis Partnership. •