BUILDING DROP-SIDED

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

BODIES

for heavy duties

" I TOOK the liberty of looking I around that new drop-sided

lorry of yours, Hardy," said Hawkins, another lorry operator.

"There are one or two features about it which I shall certainly have in any new one I may buy in the future.

Your lorry is not particularly large, but I notice that each side drops in two portions.

The central stanchion gives support where it is most needed, between the two ends of the loading portion, also the sides are easier to handle, because they are smaller and lighter. I'm just wondering, however, whether you are likely to discover that the central stanchion is in the way, sometimes, when you are unloading."

" It would be," replied Hardy, "if I nad any tong, heavy articles lying on the floor which I wanted to unload sideways, but you can have removable centre stanchions similar to those which are often fitted at the rear corners. But what other

feature was it that took your eye? It

wasn't the tailboard, by any chance?"

Tailboard Features that Provide Increased Strength.

"Yes, it was," said Hawkins. "I noticed that the tailboard irons were stouter •than usual and the edges were bound with a light channel plate. A tailboard made of three or four boards or planks held together with the usual i4nside and outside plates is satisfactory if the tailboard be used to enclose only the back of the body, or is carefully treated as a platform when loading or unloading, but you know what often happens.

"A heavy case is dumped on the outer edge, which, in time, is split off. Overloading of the tailboard a24

also bends the irons. If you are

standing in a busy thoroughfare, a lorry is almost sure to pass you with a damaged tailboard.

"But," continued Hawkins, " have yet to see a broken tailboard on a brewer's lorry. No doubt, long experience with heavy barrels has made it traditional that strength should receive first consideration."

" The tailboard should certainly be very strong," agreed Hardy. "After all, it has often to bear as much weight as a corresponding area of the floor, apart from any extra stress when loading. It certainly has direct support from the side chains, but there is a considerable difference in strength between the tailboard irons and the cross-hearers which support the floor."

"Don't you think the timber of the tailboard should be stouter?" suggested Hawkins.

Considering the Weight Factor.

"Not necessarily," replied Hardy. "The weight factor must not be

overlooked. A little extra weight may be added by having a stout wood framework for the tailboard, so that it is stiffened all around the edges and across the centre. Of course, if you have a framed tailboard, the sides should be built to match. This style of construction gives the lorry a distinctive appearance, especially if one• or two rounded corners be introduced."

"But don't you think," commented Hawkins, "that the ordinary plank-sided lorry would be stronger if the hinge irons were of channel section, instead of the usual flat or half-round ones?"

"Yes," agreed his friend, "and for a small extra cost you could have light-alloy channels, instead of mild steel."

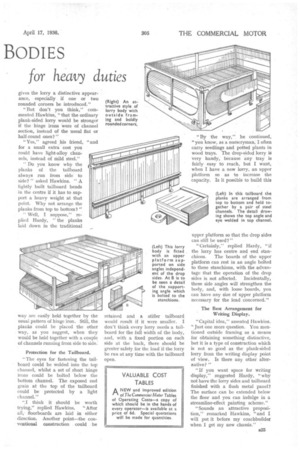

" Do you know whir the planks of the tailboard always run from side to side? " asked Hawkins. " A Lightly built tailboard bends in the centre if it has to support a heavy weight at that point. Why not arrange the planks from top to bottom?"

" Well, I suppose," replied Hardy, "the planks laid down in the traditional

way are easily held together by the usual pattern of hinge iron. Still, the planks could be placed the other way, as you suggest, when they would be held together with a couple of channels running from side to side:

Protection for the Tailboard.

"The eyes for fastening the tailboard could be welded into the top channel, whilst a set of short hinge irons could be bolted below the bottom channel. The exposed end grain at the top of the tailboard could be protected by a light channel."

".I think it should be worth trying," replied Hawkins. "After all; floorboards are laid in either direction. Another point—the conventional construction could be

retained and a stiffer tailboard would result if it were smaller. I don't think every lorry needs a tailboard for the full width of the body, ,and, with a fixed portion on each side at the hack, there should be greater safety for the load if the lorry be run at any time with the tailboard open. "By the way," he continued, "you know, as a nurseryman, I often carry seedlings and potted plants in wood trays. The drop-sided lorry IS very handy, because any tray, is fairly, easy to reach, but I want, when I have a new lorry, an upper platform so as to increase the capacity. Is it possible to build this

(Left) In this tailboard the planks are arranged from top to bottom and held together by a pair of steel channels. The detail drawing shows the top angle and eye welded in top channel.

upper platform so that the drop sides can still be used?"

"Certainly," replied Hardy, "if the lorry has centre and end stan chions. The boards of the upper platform can rest in an angle bolted to these stanchions, with the advan tage that the operation of the drop sides is not affected. Incidentally,

these side angles will strengthen the body, and, with loose hoards, you can have any size of upper platform

necessary for the load concerned."

The Best Arrangement for • Writing Display.

"Capital idea," assented Hawkins.

"Just one more question. You mentioned outside framing as a means for obtaining something distinctive, but it is a type of construction which is not so good as the plank-sided lorry from the writing display point

of view. Is there any other alternative? "

"If you want space for writing

display," suggested Hardy, "why not have the lorry sides and tailboard

finished with a flush metal panel? The surface can be extended below the floor and you can indulge in a streamline-effect painting scheme." "Sounds an attractive proposi

tion," .remarked Hawkins, "and I will put it before my coachbuilder when I get my new chassis."