NO LET-UP IN DESIGN PROGRESS

Page 166

Page 167

Page 168

Page 173

If you've noticed an error in this article please click here to report it so we can fix it.

THE number of ISO and freight containers to be displayed at Earls Court is relatively small compared with the number of companies known to have made plans for the production of containers. But it is certain that the examples exhibited will create a great deal of interest.

Bulk vehicles of various types will again be a prominent feature of the Show, and it is pertinent that the types of material that can be discharged pneumatically have increased in variety in the past two years. Advances in refrigeration and insulation methods will also be in evidence, together with allied improvements in bodybuilding techniques, and although at the time of going to press with this preview it would appear that interest in demountable bodies has waned to some extent, last-minute surprises may well prove that this impression is invalid.

Despite the critical national economic conditions, the bodybuilding industry is obviously buoyant and this may be explained by the growing appreciation on the part of operators that foresight in selecting the right type of body for the job is often the best way to economize.

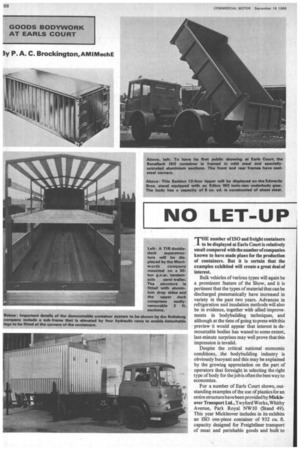

For a number of Earls Court shows, outstanding examples of the use of plastics for an entire structure have been provided by Mickleover Transport Ltd., Twyford Works, Whitby Avenue, Park Royal NW 10 (Stand 49). This year Mickleover includes in its exhibits an ISO one-piece container of 932 Cu. ft. capacity designed for Freightliner transport of meat and perishable goods and built to

British Railways specifications.

Following the concern's normal practice, the panels comprise a sandwich of inner and outer skins of colour-impregnated reinforced plastics and a core of polyurethane rigid foam having a thickness of 4.25 in. which is suitably reinforced at all stress points. A rechargeable solid carbon-dioxide unit is fitted in the roof and full-depth doors having rubber seals afford an air-tight closure. Meat rails can be fitted in the roof to accommodate a suspended load and the containers may be stacked fourhigh. The tray base and perimeter frame are of mild steel and eight special lifting castings are incorporated in the structure.

In contrast, the 1,080 Cu. ft generalpurpose ISO container to be exhibited by the Duramin Engineering Co. Ltd., Stonefield Way, Middx., (Stand 36) is constructed of steel and aluminium alloy and has W-section exterior side-framing and a hardwood floor, provision being made for lifting by the use of four corner castings or intermediate recessed shackles. The container has a tare weight of 36 cwt., allowing for a distributive floor load of 18 tons 4 cwt., and is designed for a gross rating of 20 tons.

Making its first public appearance, an ISO container of mild-steel-and-aluminium construction is to be shown by Bonallack and Sons Ltd., Paycocke Road, Basildon, Essex, on Stand 24, while Rollalong Ltd., Ringwood, Hants., (Stand 88) will feature an ISO container of the same dimensions (19 ft. 10.5 in. by 8 ft. by 8 ft.) lined with waterproofed plywood, in addition to their Lift-Off demountable body system.

Basically similar to the system demonstrated at the 1964 Show the demountable unit displayed probably represents a design trend that is likely to find increasing acceptance by operators who require a body that can be demounted "anywhere" without the aid of costly capital equipment. After the container sub-frame has been raised by four hydraulic rams, detachable legs are fitted in apertures at the corners, the frame is lowered and the vehicle can be driven away.

Possibly, however, the Key/taloa type of demountable body system to be displayed by James Cocker and Sons (Southport) Ltd. on Stand 104 will have more widespread acceptance because the hydraulic elevating mechanism is incorporated in the detachable legs (which are fitted with castered wheels) and in particular applications it is unnecessary to carry the legs on the vehicle, with a consequent benefit with regard to payload. If it were necessary to unload the container at both ends of a run the leg sets could be duplicated.

Of more limited application, but useful for changing bodies used on a seasonal basis, a demountable system is applied to a 825 Cu. ft. lightweight container to be displayed by Arlington Bodybuilders Ltd., High Road, Ponders End, Enfield, Middx. (Stand 92) which can be removed when unladen with the aid of tubular members, placed under the body, and four jacks.

A new type of system for transferring, rather than demounting, containers will be shown by R. Murtitt Ltd., Weasenha Lane, Wisbech, Cambs. on Stand 37 the form of an articulated trailer incorpor ting built-in powered mechanisms for levellir the frame and for transferring the contain sideways from or to the platform of a rl wagon or other vehicle, or a loading IN deck. It is notable that the system cate for containers of 40 ft., 30 ft., 20 ft. ar 10 ft.

A relatively large number of vans will I found equipped with a roller or trac conveyor system designed to facilita interior handling of palletized goods an depending upon the type of traffic involvc and in some cases the depot facilities, th method obviously represents the be approach to easy handling in many typ of operation.

Duramin (Stand 36) have been in ti forefront in practical investigations operators' handling needs, and their use pneumatically-elevated roller tracks ( equivalent systems) is a notable example providing free movement of pallets manual as well as stability in transit. The trolle track system produced by Joloda Transix Equipment Ltd. (accessory Stand 3i J-M) has gained widespread acceptan since its introduction five or six years al and is fitted to many of the vans to exhibited at the Show. Reiterating an o repeated claim for the use of tracks rails, it is pertinent that they offer opportunity to employ lighter flooring, as the weight of the load can be directly imposed on the cross-bearers.

The progress that is likely to be made in bulk transport in part depends on the range of material that can be handled by the discharge system in addition to the bulk and payload capacity of the vehicle, speed of discharge and depot facilities required. It is appropriate to emphasize that the requirements of the "small man" are often very different to those of a large operator who is a member of a group having substantial capital resources.

While few technical details have been released of the new Hydroject Mk. IIIA non-tipping 540 Cu. ft. pneumaticallydischarged powder tanker of aluminium construction to be exhibited by the maker, Atkinson's of Clitheroe Ltd., (Stand 126) the fact that it can handle a range of powders varying in density from 30 lb. per Cu. ft. to 90 lb. per cu. ft. gives promise that the vehicle will find a ready market. Atkinson's describe the unit as a"conapletely new concept". Products that have been successfully handled by the machine include light soda ash, cement, sodium bicarbonate, tripolyphosphate and ground feldspar, and loads have been discharged to a silo up to 60 ft.

Announced a week ago by Charrold Ltd., St. Peter's Road, Huntingdon, a completely new pneumatically-discharged vehicle designed to handle granular materials, will be displayed by the maker on Stand 141. It is known as the Tippermatic and as

the name implies discharges automatically when tipped. Features include chamfered bottom corners that direct the material into the rotary valve and thence to the outlet through a high-frequency low-amplitude vibrator panel.

A new discharger of 12 in. dia. is a feature of the 600 cu. ft. pneumatic type bulk body that will be shown by Dunnspencer Bulkilo Ltd. on Stand 152, the discharger being fed by hydraulicallydriven twin-opposed vibrating hoppers. A Godfrey Roots type blower is employed, and of special note two extra cam-locking mechanisms afford an alternative position for the bulkhead. The body is tipped by a front-end gear and the system is particularly suitable for handling animal foodstuffs, grain and so on.

These bulk-discharge methods may be compared with the auger system that is a feature of the semi-trailer-mounted Bulkveyor designed to handle agricultural produce to be exhibited by W. B. Bawn and Co. Ltd. on Stand 127, which the manufacturers claim has found increasing favour since the 1964 Show. Three augers are used, one mounted transversely at the rear of the tipping body, one in a vertical duct and one in the boom.

A guarantee of thermal performance is symptomatic of the scientific approach to refrigeration and is now typical of the leading makers of insulated and refrigerated bodies. For example a differential of 33.8

Btu/hr./°F is guaranteed by Bonaflack Refrigerated Vehicles Ltd. ill the case of a refrigerated delivery van to be displayed on Stand 23, which is of Monocore frameless construction. Insulation is provided by expanded p.v.c. sandwiched between light alloy panels and the van is refrigerated by a Prestcold AS200/L unit and four Winget-Dole holdover plates.

In common with a number of exhibitors, Bonallack also employ Polarstream liquidnitrogen refrigerating units, and at Earls Court will exhibit a Coldsaver 500 cu. ft. van equipped with a unit of this type. Also having a guaranteed thermal performance, the van is insulated with 3 in. polyurethene slab, applied to the walls and roof and 3 in. of expanded p.v.c. overlaying the resinbonded plywood floor. The insulant is covered with tongued-and-grooved softwood boards and a floor surface of lightalloy chequer plate which is argon-arc welded into one piece.

Two completely different types of plastics bodied vehicles may be appropriately mentioned in the same paragraph, the first being a 5,300 gal. filament-wound glassreinforced tank to be exhibited by Gloster Sato Ltd. on Stand I 1 1 and the second a laminated glass-fibre platform body that will be displayed by Road Transport Services (Hackney) Ltd. on Stand 83. Supported on glass-fibre bearers fitted with light-alloy stiffeners, the RTS body is of special interest in that the ability of the body to flex with the vehicle chassis is cited as a particular merit by the company.

Body structures generally should ideally have such flexibility, the problem in the case of a typical tanker being that the inherent rigidity of the shell necessitates the use of mountings that provide for independent flexing of the chassis frame. Gloster Sam are probably the only makers in this country who build tankers the entire structure of which is designed as a rigid unit. If a tanker is articulated, torsional stress is substantially reduced by virtue of the coupling, which acts as a flexible mounting, but in the interests of low stressing and lightness, it is essential to employ a bogie suspension and bogie mountings of appropriate characteristics. Of related significance, the Gloster Saro tank is mounted on a Dyson Aeroride bogie.

Promising to be a tanker highlight of the exhibition, a 6,000 gal. six-compartment mild-steel tank will be displayed by W. P. Butterfield (Engineers) Ltd. on Stand 105, the chief interest afforded by the vehicle being that it is mounted on a prototype steerable-axle six-wheeled trailer. By obviating tyre scrub up to the limit of angular movement of the steered wheels, bogie steerability should also be "kind" to the bodywork as well as the chassis frame and thus provide for a reduction in body and frame weights.

Tipping gear news is mainly, centred on the equipment of frameless tipping trailers, in particular on the Radilift and the Hy-Spill to be shown respectively by Neville Industries (Mansfield) Ltd. on Stand 32

and by Telehoist Ltd. on Stand 50. The unusual feature of the Radilift is the incorporation of twin. short-stroke rams in the radial-arm assembly, which compares with the more conventional long-stroke single ram of the Hy-Spill, the base of which is mounted on the fifth-wheel coupling. Both are fitted with an aluminium body, the U-shaped body of the Radilift being .of the well-known Neville sectioned type. The Hy-Spill is designed for a g.v.w. of 28/32 tons and corresponding payloads up to 21 tons, while tipping angles up to 50 degrees can be accommodated. Hauled by a Paden 6A6/5 tractive unit, the unladen weight of the Radilift is 11 tons 10 cwt. which gives a payload of 20 tons 10 cwt.

Details of power take-off design may be as important to a tipping-body specialist as the ram gear, and of related interest Edbro Ltd. have produced a new range of power take-off units which are applicable to all Edbro gears having six-cylinder pumps. Examples will be shown by t three companies of the Edbro group, narnt Edwards Bros. (Tippers) Ltd. (Stand 2 Pilot Works Ltd. (Stand 22) and Brornib and Edwards Ltd. (Stand 25). The get feature p.v.c. plastics-cased pre-greas weather-proofed cables which are part ularly suitable for vehicles fitted with I cabs, the long cable runs providing fingercontrol.