A tapered effect

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

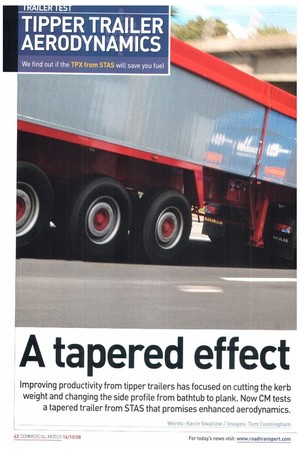

Improving productivity from tipper trailers has focused on cutting the kerb weight and changing the side profile from bathtub to plank. Now CM tests a tapered trailer from STAS that promises enhanced aerodynamics.

Words: Kevin Swallow/ Images: Tom Cunningham Aerodynamics is billed as a solution to several industry ills: boosting your green credentials, reducing your carbon footprint, cutting your fuel bill...

Indeed, the potential savings from aerodynamic trailers can be huge, as can the penalties for installing a system that isn't properly used, The consensus is that short-haul projects and stop/start operations won't reap many benefits.

Each system CM has recently assessed — Cartwright's Cheetah system, Don-Bur's Teardrop, Montracon's sloping double-decker — offers improvements over standard designs, verified by a mix of controlled constant-speed testing and research conducted out on the open road.

So, is the question which is the best aerodynamic application for any given operator? Perhaps not. Other trailer-makers, such as Schmitz Cargobull (UK) and Lawrence David ('On the efficiency drive', CM 25 September), have chosen the traditional manufacturing route, preferring to remove weight from the trailer to help operators deliver better fuel economy and/or improve payload and productivity.

Not the fuel picture

It could all be a marketing ruse — manufacturers openly dismissing innovative designs while secretly wishing they had thought of them themselves. Or it could be that genuine engineering nous is resulting in decisions that maintain the status quo.

Either way, the current focus is still on aerodynamics.

and the latest trailer-maker to incorporate it into its products is STAS, which we conducted a profile on earlier in the year ('Made in Belgium CM 22 May). CM has looked at tipper aerodynamics before with GT Fruehauf (CM 22 August 2002). Back then, it was bathtub versus smooth planksider. This time, it's smooth versus slick.

The key to aerodynamics is manipulation of the first point of contact. Truck manufacturers compromise style and presentation to accommodate airflow with rounded corners and air management kits. All trailer-builders can do is help the air continue on its merry way and not create too many barriers or an overabundance of drag.

Tip for the top

The tipper trailer could conceivably be the best prospect for enhancing aerodynamics across the trailer industry. Its load.space doesn't have to be uniform. Weight issues permitting, the load can be moved forward or back with part of the trailer narrowed.

This is the approach STAS has taken with the TPX. Granted, it hasn't gone too far down this route, but it has adopted a conical body and worked a continuous ridge along the body that directs the air downwards, creating a small degree of lift.

The rear door is angled down to smooth air coming over the sheet and reduce drag; there are also shark fins on the wheelarches and a clear passage under the chassis for air to pass through. Which feature most improves the aerodynamics is debatable, but it could be that each has a slight effect, together just enough to save fuel.

The TPX9.4 aggregate trailer has an aluminium chassis and the width of the bullet design is 2,200mm at the front and 2,300mm at the rear. It is 9,485mm long and has a 40yd3(30.5m3) volume. The floor is 8mm thick and it has 4mm sides.

TPX's chassis design is identical to the older TPOPP, which it was compared against on the fuel runs. The latter is a double-skin plankside trailer, making it more versatile than the single-skin aggregate. The TPOP trailer is 9,445mm long, 2,430mm wide and 1,450rrun high.

Both trailers ran on DaimlerChrysler axles with Alcoa alloy wheels using 386/65 R22.5 Goodyear Omnitrac MST tyres. The TPX weighs in at 5,600kg, which includes an onboard weigher and a 200kg Camaro sheet. It is 578kg lighter than the TPOP, which has a 90kg weigher and 132kg alloy wheels.

With the 7,704kg MAN TGS LX 6x2 440hp tractor used for the test runs, the TPX delivers a potential 30,696kg payload, whereas the TPOP and tractor offers 30,118kg. •