THE LORRY AND THE LOAD.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

How the Magnitude of the Load Affects the Engine and Chassis.

I N ALL classes of haulage work there are bound to be occasions on which vehicles are run with

small loads or with no loadsat all. Overloading and over-speeding are obvious abuses. which should not be permitted, and will not be dealt with here, tont variations in load between zero and the full capacity are. legitimate and important. Many users of commercial vehicles are not at all certain as to the effect of these conditions on the wear and tear and the running costs, and it is for the elucidation of these points that this article has been written.

As regards petrol consumption, it is obvious that the lowest cost per mile per ton of pay-load will be

obtained when the vehicle is fully laden. For example, if the chassis weight is ,31 tons, load 3 tons, and consumption a gallon per 50 (gross) ton-miles, then a short calculation will show that the petrol cost per mile per ton of pay-load is about Id. Now, suppose that the load is reduced to l tons, the (gross) ton-m.p.g. remaining at 50, the same calculation shows the cost to be lid.

As. a matter of fact, the difference will be greater than this, because the vehicle will not be capable of 50 ton-m.p.g. at the lighter load. This is due to the fact that both the engine and transmission function more efficiently when the full:power is being taken.

Anyone who has carried out bench tests on lorry engines will know that there are two factors which influence the efficienty--namely, the throttle opening and the cooling-'water temperature. Generally speaking, much better results are obtained at full throttle and with temperatures of 170 to 190 degrees F. than are 'possible at half-throttle and tempera'Lures of, say, 120 to 150 degrees F. This is partly due to the decreased viscosity of the oiland improved carburation at higher temperatures, and to the increased compression pressures at full throttle. Consequently, the engine will work more efficiently when the lorry is fully laden.

As regards transmissive efficiency, the relative effects of friction in the hearings and gears and on temperature of the lubricant are such that the 1330 efficiency increases with the load up to a certain 'point. Combining the engine and transmission efficiencies, it will usually be found that a lorry capable of 50 ton-m.p.g. when fully laden will only give a figure of about 40 when running light.

Turning to the consideration of wear and tear,

there would appear to be many conscientious drivers and owners who have vague apprehensions as to the possibilities of " overstraining " the engine by prolonged work at full throttle. This is rather a curious misconception, because no matter what load is being carried the engine cannot possibly be made to deliver more than the power which it was designed to withstand.

Compression and explosion pressures are definitely fixed by the design and carburation, and the work.ing parts are dimensioned accordingly. Short of increasing the compression pressure, or supercharging, the engine cannot be overstrained in the way that a frame or springs can be misused.

The only effect of prolonged running at full throttle will be to increase the rate of wear and reduce the periods of time. between decarbonizations and overhauls.. Many manufacturers test their engines, when in the experimental stage, for 100 hours' continuous running at full throttle, so that the owner need have little to fear as to the capacity of his engine to withstand these conditions. The transmission can also be relied upon to withstand prolonged running under full load. The rate of wear is, of course, somewhat increased, but if lubrication be carefully attended to the increase will be slight. In all makes of repute an ample factor of safety is allowed in the design of shafts and gears, so that there is small likelihood of failure.

The clutch is, perhaps, the one part of the transmission in which trouble may be anticipated in some cases. With large engines transmitting power at low speeds, the torque (or twisting effect) on the clutch is considerable and ` the diameter of the friction surfaces transmitting the torque is often limited by considerations of space. Consequently, the pressure on clutch linings is sometimes higher than is advisible, and prolonged running at full load may cause clutch slip and ether troubles.

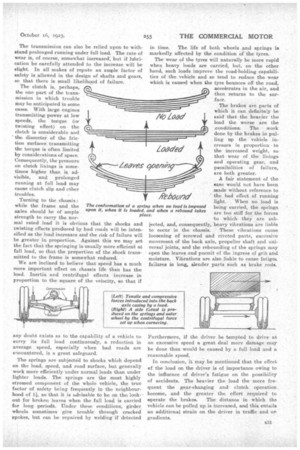

Turning to the chassis : while the frame and the axles should he of ample strength to carry the normal rated load it is obvious that the shocks and twisting effects produced by bad roads will be. intensified as the load increases and the risk of failure will be greater in proportion. Against this we may set the fact that the springing is usually more efficient at full load, so that the proportion of the shock transmitted to the frame is somewhat reduced.

We are inclined to believe that speed has a much more important effect on chassis life than has the load. Inertia and centrifugal effects increase in proportion to the square of the velocity, so that if any doubt exists as to the capability of a vehicle to carry its full load continuously, a reduction in average speed, especially when bad roads are encountered, is a great safeguard.

The springs are subjected to shocks which depend on the load, speed, and road surface, but generally work more efficiently under normal loads than under lighter loads. The springs are the most highly stressed component of the whole vehicle, the true factor of safety being frequently in the neighbourhood of 11 so that it,is advisable to be on the look-out for broken leaves when the full load is carried for long periods. Under these conditions, girder, wheels sometimes give trouble through cracked spokes, but can be repaired by welding if detected in time. The life of both wheels a,nd springs is markedly affected by the condition orthe tyres. The wear af the tyres will naturally be more rapid when hea.vy loads are carried, hut, on the other hand, such loads improve the road-holding capabilities of the vehicle and so tend to reduce the wear which is caused when the tyre bounces off the road, accelerates in the air, and then returns to the surface.

The brakes are parts of which it can definitely be raid that the heavier the lead the worse are the ;conditions. The work done by the brakes in pulling up the vehicle increases in proportion to the increased weight. so that wear of the linings and operating Fear, and possibilities of failure, are both greater.

A fair statement of the ease would not have been made -without reference to the bad 'effect of running light. When no load is being carried, the springs are too stiff for the forces to which they are subjected, and, consequently, heavy vibrations are liable to occur in the chassis. These vibrations cause loosening of screwed and riveted parts, excessive movement of the back axle, propeller shaft and universal. joints, and the rebounding of the springs may open the leaves and permit of the ingress of grit and moisture. Vibrations are also liable to cause fatigua failures in long, slender parts such as brake rods.

Furthermore, if the driver be tempted to drive at an excessive speed a great deal more damage may be done than would be caused by a full load and a reasonable speed.

In conclusion, it may be mentioned that the effect ef the load on the -driver is of importance owing to the influence of driver's fatigue on the possibility of accidents. The heavier the load the more frequent the gear-changing and clutch operation become, and the greater the effort required to operate the brakes. The distance in which the vehicle can be pulled up is increased, and this entails an additional strain on the driver in traffic and on gradients. B31