For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the render of the best letter which we publish on this page ; all others are paid for at the rate of a penny a line, with an allowance for photographs." All notes are edited-before being published. Mention your employer's name, in confidence, as evidence of good faith. Address, D., M. and F., "The Commercial Motor," 7-15, Rosebery Avenue, London, B.C. 1.

Lamps Alight— Light your lamps at 9.16 in London, 10.21 in-Edinburgh, 9.39 in Newcastle, 9.36 in Liverpool, 9.27 in Birmingham, 9.25 in Bristol, and 10.20 in Dublin.

When Dismantling Steam Engine Pistons.

The sender of the following communication has been awarded the 10s. prize this week.

[1856] " J.H.R." (Leiston) writes :—" Repairs to steam wagons are generally viewed by the average garage man with a certain amount of trepidation. in fact, I believe that this state of mind on the part of the majority of motor agents accounts for all the prejudice which certainly exists in some quarters against this type of vehicle. As a matter of fact, carefully hancllea, there is nothing really difficult about the vehicles to repair. It is a case of being 'simple, when you know how.' A typical instance is that of the removal of the piston and piston rod from the cylinder. Most steam wagon makers secure the crosshead to the piston rod by means of a cotter or wedge which draws a tapered end of the rod into a correspondingly shaped hole in the shank of the crosshead.

"As the fit of the rod into the crosshead must of necessity be a good one, a little difficulty is experienced when it is desired to separate these. two components, and in many cases, M order to facilitate this procedure, the piston_ rod is screwed for a short distance just behind the crosshead, and a nut is fitted in place : it is intended that this nut should be used to force the crosshead from the rod. When 'dismantling the first procedure is of course, to remove the cotter. This can generally )oe accomplished quite readily by means of an ordinary hand hammer. The careful mechanic usually uses a drift or punch or brass or copper.This renders the process of hammering more convenient, and also saves the edge of the cotter from being burred up. Having removed the cotter, it will almost invariably be found that the crosshead is tight on the piston.

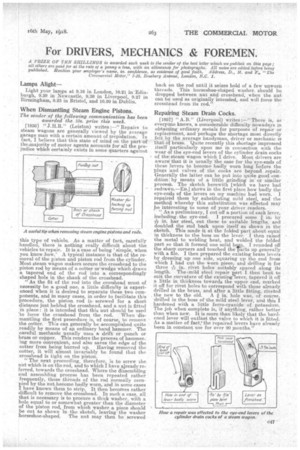

"The next proceeding, therefore, is to screw the nut which is on the rod, and to which I have already referred, towards the crosshead. Where the dissembling and assembling process has been repeated rather frequently, those threads of the rod normally occupied by the nut become badly worn, and in some cases I have known them to strip. It then becomes rather difficult to remove the crosshead. In such a case, all that is necessary is to procure a thick washer, with a hole equal to or somewhat greater than the diameter of the piston rod, from which washer a piece should be cut as shown in the sketch, leaving the washer horseshoe-shaped. The nut may then be screwed back on the rod until it seizes hold of a few unworn threads. This horseshoe-shaped washer_ should be dropped between nut and crosshead, when the nut can be used as originally intended, and will force the crosshead from its rod.'

Repairing Steam Drain Cocks.

[18571 " A.B." (Liverpool) writes There is, as

everyone knows, a considerable difficulty nowadays in obtainingordinary metals for purposes of repair or replacement, and perhaps the shortage most directly felt by the average handyman, driver or mechanic is that of brass. Quite recently this shortage impressed itself particularly upon me in connection with the wear of the eye-end levers of the cylinder drain cocks of the steam wagon which I drive. Most drivers are aware' that it is usually the case for the eye-ends of these levers to becomebadly worn long before the plugs and valves of the cocks are beyond repair. Generally the latter can be put into quite good condition by means of a little grinding in or similar process. The sketch herewith [which We have had redrawn.—En.l shows in the first place how badly the eye-ends of the levers on my machine had worn. I repaired them by substituting leild steel, and the method whereby this substitution was effected may pe interesting to some of your driver readers. "As a prehmin.ary, I cut off a portion of each lever, including -the eye-end. I procured some I in: by sk in, bar steel, -cut these to suitable lengths, and doubled the end back upon itself as shown in the sketch. This made it at the folded part about equal in thickness to the boss on the lever. T then raised the metal to welding heat, and welded the folded part so that it formed one solid begs. I rounded off the sharp corners and touched the parts up generally with a file. I then prepared the existing brass levers by dressing up one side, squaring up. the end from which I had cut the Worn piece, and drilling it for three Ain. rivet holes suitably spaced along its length. The%mild steel repair part I then bent to suit the curvature of the existing-lever, tapered it off a little in thickness towards the upper end, marked it off for rivet holes to correspond with those already drilled in the brass, and after a' little fitting, riveted the new to the old. A # in. hole was, of course, 'drilled in the boss of the mild steel lever, and this I hardened with a little ferro-cyanide of potassium. The job when complete is, if anything, rather better than when new. It is more than likely that the hardened lever will outlast the valve to which it is fitted. As a matter of facts' the repaired levers have already been in constant use for over 20 snouths."