Light but Game

Page 58

Page 59

Page 60

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

By JOHN F. MOON

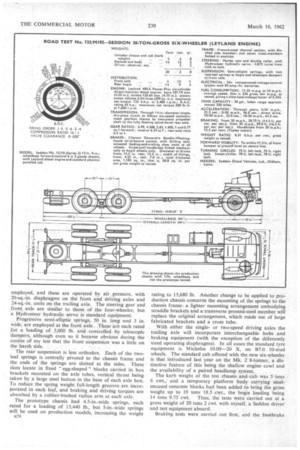

ONE of the difficulties associated with six-wheeled chassis having a single-drive rear bogie is that of traction. This can sometimes be solved so far as normal road running is concerned by employing suspension systems which can put a higher proportion of the overall bogie loading on the driving axle, but whilst designs of this type have been found to perform satisfactorily on hard, level surfaces, traction is not always good on uneven ground because the degree of articulation permitted by the bogie suspension is not always sufficient to enable the driving wheels to stay on the ground.

A novel approach to solving this problem has been made by Seddon Diesel Vehieles, Ltd.. whose latest six-wheeler incorporates a high-articulation, two-spring bogie, each of the springs containing only two leaves. ' The method of mounting the aides to the springs permits i valuable amount pf inter-axle vertical movement, so much so that during one stage of a recent road test of a prototype vehicle -a difference of 11 in. was measured between the heights of the two near-side hubs while successfully reversing up a short, grass-covered slope. Many other types of singledrive six-wheeler would have been unable to perform this manceuvre because as the trailing wheels rose up the slope they would tend to lift the driving wheels also.

Because there are only two leaves in each spring, this Seddon bogie offers a second advantage—namely, that of weight saving. Although the leaves are fairly hefty I understand that between 1.5 and 2 cwt. is saved compared with the weight of a conventional four-spring-and-balance-beam suspension layout, the articulation of which would be comparatively small in any case.

The six-wheeler to which this new bogie has been applied is the Mk. 15/10 (Series 2), which was introduced at the Scottish Motor Show last November. The machine is rated for a gross weight of 20 tons, and the standard power unit is the Leyland 400-S six-cylinder direct-injection unit, which has a net power output of 125 b.h.p. at 2,400 r.p.m., with a peak torque rating of 300 Ib.-ft. at 1,600 r.p.m.

This torque output is a little on the low side for a 20-ton vehicle, even allowing for the provision of an Albion fivespeed gearbox as standard equipment, with the option of a sixth overdrive ratio, but the prototype tested had a

6.5-to-1 rear axle, whilst production models will have a final-drive reduction of 6.83 to 1. Although this will reduce the maximum overdrive speed (at engine governed speed) from 57 m.p.h. to 51 m.p.h., it will undoubtedly have a beneficial effect on gradient performance.

Even better overall performance would, however, be given by the Eaton two-speed axle which is to be made a production option. This will have ratios of 7.02 and 5.14 to 1 which will combine with the 0.77-to-1 top gear of the overdrive gearbox to give effective overall ratios of 5.6 and 3.9 to 1, with governed top speeds of 50 m.p.h. and 72 m.p.h. respectively and a bottom-gear, low-ratio gradient ability of about .1 in 6.

Thus, the proposed standard vehicle with the 6.83-to-1 axle will have a top speed of approximately 51 m.p.h. (not allowing for governor run-up) when the optional overdrive ratio is fitted, which will make it suitable for the operator in reasonably level country who cannot legally make use of a higher speed. For working in hilly areas, however, and where full use can be made of motor

ways, 1 consider it advisable that the Eaton axle and the overdrive ratio be specified. The 12 available ratios will give an enhanced overall performance, improve the already good fuel economy, and add to the other attractions of this chassis, such as good driving conditions, low weight, above average traction over-rough ground and comparatively low "Price.

As its nomenclature implies, the Seddon Mk. 15/10 (Series 2) six-wheeler is a derivation of the Mk. 15/10 14-ton-gross four-wheeler.' The prbtotype tested had a 9-in. x 2.5-in. x 0.25-in, frame with' full-length flitch plates .and seven cross-members bolted in place. Heavier side members without flitch plates are to be employed in production, the proposed dimensions being 10,875 in. x 3 in. x 0.3125 in. Another change affecting the frame is that production models will have a wheelbase of 17 ft., whereas the prototype's vvheelbase was 17 ft. 9 in.: this should help toreduce a rather large turning circle.

The braking _system also differs from that Of the

• Mk. 15/10 four-wheeler. Girling cam-actuated units, giving the impressively large lining area of 1,181 sq. in., are n25

employed, and these are operated by air pressure, with 20-sq.-in. diaphragms on the front and driving axles and 24-sq.-in, units on the trailing axle. The steering gear and front axle are similar to those of the four-wheeler, but a Hydrosteer hydraulic servo is standard equipment.

Progressive semi-elliptic springs, 50 in. long and 3 in. wide, are employed at the front axle. These are each rated forrn a loading of 5,000 lb. and controlled by telescopic dampers, although even so it became obvious during the course of my test that the front suspension was a little on the harsh side.

The rear suspension is less orthodox. Each of the twoleaf springs is centrally pivoted to the chassis frame and the ends of the springs are slotted at the sides. These slots locate in fixed " egg-shaped " blocks carried in box brackets mounted on the axle tubes, vertical thrust being taken by a large steel button in the base of each axle box. To reduce the spring weight full-length grooves are incorporated in each leaf, and braking and driving torques are absorbed by a rubber-bushed radius arm at each axle.

The prototype chassis had 4.5-in.-wide springs, each rated for a loading of 13,440 lb., but 5-in.-wide springs will be used on production models, increasing the weight n26 rating to 15,680 lb. Another change to be applied to production chassis concerns the mounting of the springs to the chassis frame: a lighter mounting arrangement embodying straddle brackets and a transverse pressed-steel member will replace the original arrangement, which made use of large fabricated brackets and a cross tube.

With either the singleor two-speed driving axles the trailing axle will incorporate interchangeable hubs and braking equipment (with the exception of the differently sized operating diaphragms). In all cases the standard tyre equipment is Michelin 10.00-20 X. on B7.0 10-stud wheels. The standard cab offered with the new six-wheeler is that introduced last year on the Mk. 2 8-tonner, a distinctive feature of this being the shallow engine cowl and the availability of a paired headlamp system.

The kerb weight of the test chassis and-cab was 5 tons 6 cwt., and a temporary platform body carrying steelencased concrete blocks had been added to bring the gross weight up to 19 tons 18.5 cwt., the bogie loading being 14 tons 9.75 cwt. Thus, the tests were carried out at a gross weight of 20 tons 2 cwt. with myself, a Seddon driver and test equipment aboard.

Braking tests were carried out first, and the footbrake figures from both 20 m.p.h. and 30 mph were good, average maximum retardations of 62 per cent. being recorded from both speeds. During each test there was evidence of slight lag in the air-pressure system, whilst the trailing-axle wheels showed a tendency to lock, particularly at the off side, but slight locking and hopping of the rear wheels of a two-spring bogie when braking hard are difficult to eliminate.

It is rare to find an unassisted single-pull handbrake on a vehicle of this weight, and the fact that the highest Tapley-meter reading that could be obtained from 20 m.p.h. was 13 per cent. (the average figure being 12.5 per cent.) helps to explain why. Even with a variable-ratio linkage such as that used on the Seddon it is virtually impossible to get over 15 per cent. when running at 20 tons gross. The manufacturers are well aware of this, however, and a multi-pull brake will be incorporated in production.

Using second, third, fourth and fifth gears, quite good acceleration times were recorded from a standstill up to 30 m.p.h., the absence of synchromesh on the gearbox proving to be no disadvantage when it came to changing gear quickly. Direct-drive acceleration between 10 m.p.h. and 30 m.p.h. was reasonable in view of the comparatively low torque output of the engine and the comparatively high rear axle gearing, and there was no engine or transmission roughness worth complaining of. A check of the gear speeds showed that fifth (direct) gear could be held up to about 44 m.p.h., whilst the speeds in fourth, third and second were 28, 17 and 12 respectively.

The ambient temperature during the gradient performance tests was 5°C. (41°F.), and the trials were carried out, as usual, on Buckstones Road, Shaw, a 1.75-mile hill with an average gradient of I in 12. At the bottom of the hill the engine-coolant temperature was recorded as 66°C. (151°F.). Within about two minutes of starting the climb it became necessary to drop down the gearbox into bottom gear, and this ratio was needed for 9 minutes 40 seconds out of a total climbing time of 13 minutes 22 seconds, the lowest road speed noted being 4 m.p.h.

Naturally enough, because the engine was running on the governor throughout most of the climb, the fan speed was high and the temperature rise slight, the final temperature being 67.5°C. (153.5°F.). Had the test vehicle been equipped with a two-speed axle this climbing time would have been considerably reduced as it would have split the gap between bottom gear and second.

Fade resistance was shown to be particularly high, and proved the worth of the large total lining area. The six wheeler was put through my usual severe test, which entails coasting down Buckstone Road in neutral while keeping the footbrake applied to restrict the speed to 20 m.p.h. The descent lasted 4 minutes 52 seconds, and at the foot of the hill an " emergency " stop from 20 m.p.h. produced a Tapley-meter figure of 50 per cent.—only 0.12g. less than that obtained earlier in the day when the drums were cold. The air reservoir pressure had dropped to 90 p.s.i. from its normal figure of 110 p.s.i. during the descent, but still several of the wheels marked the road heavily.

Returning up the hill. I stopped the Seddon on the steepest section, where the gradient is 1 in 8.5. Here the handbrake was shown to be only just powerful enough to prevent back

ward movement even though I applied it while holding the footbrake on fully. I then made a fairly smooth bottom-gear

restart, although there was not a great reserve of power.

Out of curiosity I did several more restarts while deliberately engaging the clutch a little more harshly than I had on the first occasion, and, as suspected, this treatment produced wheel spin—unaccompanied by forward motion.

Having turned the vehicle round, I then made restart checks in reverse. As when facing up the hill, the handbrake was only just capable of holding the vehicle, but no wheelspin took place when reverse restarts were made, although the performance in this direction was marred by the gearbox continually jumping out of reverse gear. I think this latter fault was probably caused by the gearchange linkage not having been adjusted properly, for• throughout the tests stiff gear-changing action was prevalent.

Two sets of fuel-consumption figures were taken over the same 6-mile stretch of The Broadway, Chadderton, this being a tricky out-and-return circuit involving the negotiation of six sets of traffic lights and one roundabout. On the first run we were dogged by heavy traffic and bad luck at the Eights, despite which the course was completed at an average speed of 27 m.p.h., whilst the fuel-test tank showed the consumption rate to have been 10.2 m.p.g.

In view of the conditions—which involved four hard accelerations from standstill up to over 30 m.p.h., two of them up gradients--I was satisfied with this figure, but decided to see if we would be any luckier with the traffic on a second attempt. We were, and the figure of 11.25 m.p.g. was obtained, although the average speed was slightly slower at 24 m.p.h. Even on this run one stop was made, which suggests that On a clear trunk run this vehicle should give a good 12 m.p.g. at normal cruising speeds: this is borne out by the high time-load-mileage factor of 5,424 obtained as a result of the second run.

I had noticed during the course of the day that the turning circle of this six-wheeler seemed on the large side, and I had some difficulty finding a suitable clear stretch of ground on which to measure the actual circle. Eventually, as daylight faded, I was reduced to doing this check on a rather muddy patch, and it was obvious that some frontwheel side slip was occurring On both locks a figure of 84 ft. was measured, but I am more inclined to believe the manufacturer's figure of 75 ft. Even this is somewhat greater than is generally acceptable, so it is to be hoped that the slightly shorter wheelbase of production models gives an improvement in this respect.

Adjacent to the above-mentioned muddy patch there was some rough ground, so here I took the opportunity to study the inter-axle articulation potentials of the bogie. As already detailed, the six-wheeler successfully surmounted a short, sharp grassy slope, approached from a dry concrete surface, and at maximum articulation there was a difference of 11 in. between the heights of the nearside hubs, whilst, at the same time, both off-side hubs remained more or less parallel to the line of the chassis frame. This was sufficient proof for me that the new Seddon bogie gives above-average -articulation and that its traction characteristics should be better than usual for a single-drive vehicle operating at 20 tons gross.

Taken generally the Seddon six-wheeler handled well, despite the stiff gear change. The power-assisted steering was a joy to use, good castor action being retained, and the handling never becoming too light. The brakes were fully proportional to pedal effort, and the clutch was light in operation. Slight harshness of the front suspension was responsible for some steering-wheel kick, but the use of lower rate front springs should effect a cure here.

The cab is well laid out and quite spacious, and the degree of all-round vision is good. Most of the controls are well positioned, although the two rows of unmarked electrical switches outrigged from the steering column are a little confusing. Unlike some Seddon cabs, this new design has a sheet-metal engine cowl and, whilst this folds away very neatly to give good engine accessibility, it provides little or no sound insulation, as a result of which an appreciable amount of engine noise penetrates into the cab.