Operating Experience of Motorway Coaches

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

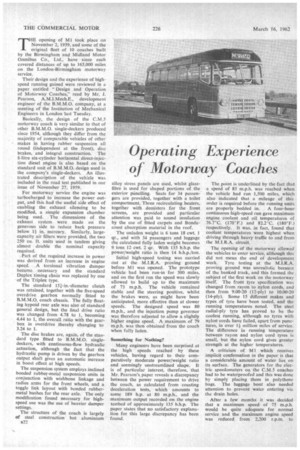

THE opening of M1 took place on November 2, 1959, and some of the original fleet of 10 coaches built by the Birmingham and Midland Motor Omnibus Co., Ltd., have since each covered distances of up to 165,000 miles on the London-Birmingham motorway service.

Their design and the experience of highspeed running gained were reviewed in a paper entitled "Design and Operation of Motorway Coaches," read by Mr. J. Pearson, A.M.I.Mech.E., development engineer of the B.M.M.O. company, at a meeting of the Institution of Mechanical Engineers in London last Tuesday.

Basically, the design of the C.M.5 motorway coach is very similar to that of other B.M.M.O. single-deckers produced since 1954, although they differ from the majority of comparable vehicles of other makes in having rubber suspension all round (independent at the front), disc brakes, and integral construction. The 8-litre six-cylinder horizontal direct-injection diesel engine is also based on the standard unit of B.M.M.O. design used in the company's single-deckers. An illustrated description of the vehicle was included in the road test published in our issue of November 27, 1959.

For motorway service the engine was turbocharged to increase the power output, and this had the useful side effect of enabling the exhaust silencing to be modified, a simple expansion chamber being used. The dimensions of the exhaust system were made on the generous side to reduce back pressure below 11 in. mercury. Similarly, largecapacity air filters were provided, the two 250 cu. ft. units used in tandem giving almost double the nominal capacity required.

Part of the required increase in power was derived from an increase in engine speed. A torsional vibration damper became necessary and the standard Duplex timing chain was replaced by one of the Triplex type.

The standard 15i-in.-diameter clutch was retained, together with the five-speed overdrive gearbox normally fitted to B.M.M.O. coach chassis. The fully floating hvpoid rear axle was also of standard general design, but the final drive ratio was changed from 4.78 to l, becoming 4.44 to 1, the overall ratio with the gearbox in overdrive thereby changing to 3.24 to I.

The disc brakes are, again, of the standard type fitted to B.M.M.O. singledeckers, with continuous-flow hydraulic actuation, although the fact that the hydraulic pump is driven by the gearbox output shaft gives an automatic increase in boost effect at high speeds.

The suspension system employs inclined bonded rubber-metal suspension units in conjunction with wishbone linkage and radius arms for the front wheels, and a toggle link layout with bonded rubbermetal bushes for the rear axle. The only modification found necessary for highspeed use was the use of heavier damper settings.

The structure of the coach is largely of steel construction but aluminium al2

alloy stress panels are used, whilst glassfibre is used for shaped portions of the exterior panelling. Seats for 34 passengers are provided, together with a toilet compartment. Three recirculating heaters, together with demisters for the front screens, are provided and particular attention was paid to sound insulation by the use of fitted carpets and Bondacoust absorption material in the roof.

The unladen weight is 6 tons 18 cwt. I qr., and with 34 passengers and luggage the calculated fully laden weight becomes 9 tons 12 cwt. 2 qr. With 135 b.h.p. the power/weight ratio is then 14 b.h.p./ton.

Initial high-speed testing was carried out at the M.I.R.A. proving ground before M1 was opened. The prototype vehicle had been run-in for 500 miles, and on the first run the speed was slowly allowed to build up to the maximum of 73 m.p.h. The vehicle remained stable and the steering positive, whilst the brakes were, as might have been anticipated, more effective than at slower speeds. The designed speed was 80 m.p.h., and the injection pump governor was therefore adjusted to allow a slightly higher engine speed. A maximum of 79 m.p.h. was then obtained from the coach when fully laden.

Something for Nothing?

Many engineers have been surprised at the high speeds reached by these vehicles, having regard to their comparatively moderate power/weight ratio and seemingly unstreamlined shape. It is of particular interest, therefore, that Mr. Pearson's paper reveals a discrepancy between the power requirement to drive the coach, as calculated from coasting deceleration tests, which amounts to some 189 h.p. at 80 m.p.h., and the maximum output recorded on the engine testbed of approximately 135 b.h.p. The paper states that no satisfactory explanation for this large discrepancy has been found. The point is underlined by the fact that a speed of 85 m.p.h. was reached when the vehicle had run 1,500 miles, which also indicated that a mileage of this order is required before the running units are properly bedded in. A four-hour continuous high-speed run gave maximum engine coolant and oil temperatures of 76.7°C. (170°F.) and 82.2°C, (180°F.) respectively. It was, in fact, found that coolant temperatures were highest when driving through heavy traffic to and from the M.I.R.A. circuit.

The opening of the motorway allowed the vehicles to enter service, although this did not mean the end of development work. Tyre testing at the IVLI.R.A. proving ground was unrealistic because of the banked track, and this formed the subject of the first work on the motorway itself. The front tyre specification was changed from rayon to nylon cords, and then from 9.00-20 (12-ply) to 10.00-20 (14-ply). Some 15 different makes and types of tyre have been tested, and the running temperatures noted. The steel radial-ply tyre has proved to be the coolest running, although no tyres with nylon cords have failed, apart from punctures, in over 11 million miles of service. The difference in running temperature between rayon and nylon cord tyres is small, but the nylon cord gives greater strength at the higher temperatures.

A criticism of MI which receives implicit confirmation in the paper is that a considerable amount of water lies on its surface. The generators for the electric speedometers on the C.M.5 coaches had to be waterproofed and this was done by simply placing them in polythene bags. The luggage boot also needed attention to prevent water entering via the drain holes.

After a few months it was decided that a maximum speed of 75 m.p.h. would be quite adequate for normal service and the maximum engine speed was reduced from 2,200 r.p.m, to 1,950 r.p.m. and the fuel delivery from 22 c.c. to 19 c.c. The power output was not reduced, partly because of a revised form of delivery valve and partly because thc governor gave a sharper cut-off due to the introduction of a spring link between its mechanism and the fuel-pump rack. Fuel consumption was improved by these changes and the coaches are averaging just over 14 m.p.g.

Another problem associated with the fuel injection equipment is failure of the governor mechanism, thought to be due to metal fatigue caused by fluttering of the governor when operating continuously near maximum speed for long periods. The interval between fuel pump changes was reduced from 24,000 miles to 16,000 miles as an interim measure, but a hydraulic governor, in which the only rotating parts are two pump gears, is now on test.

The turbochargers have given very good service and it is anticipated that cleaning and renewal of oil seals every 100,000 miles will be the only servicing necessary. Factors considered to contribute to this are efficient air and oil filtration, good combustion characteristics and the fact that the turbocharger is working well within its capacity.

The air filter elements have been given an extended life by chemical treatment, and two coaches have experimentally run 20,000 miles without them being touched. A device to give visual warning of clogging is on test. The oil filter is changed at every oil change, and average consumption of S.A.E. 20/20W oil is 2,500 m.p.g.

Engine wear, when checked on certain vehicles, proved to be comparable to that in normal stage service. The continuous demand for a high power output is evidently offset by the non-stop nature of service and the fact that optimum temperatures are maintained, as well as the high standard of .air filtration and the use of high-quality engine oil. The highest engine mileage to date is 150,000. Gearboxes and rear brakes have given

very little trouble, and a number of units have covered 165,000 miles without dismantling.

Abrasive wear, rather than wear due to aetual use, has had its effect on brake pad life, but even so this is in excess of 30,000 miles, compared to 45,000-50,000 miles in stage carriage service. Shielding of the brakes has been considered, but the higher operating temperature this would cause has deterred development of the idea, as yet.

A general examination was made at the end of the first year's running, when most of the vehicles had covered 80,000 miles. The general condition was found to be good, but certain controls in relatively exposed positions were found to be worn more than usual owing to abrasive matter being forced past the normal sealing arrangements due to the higher speeds. The sealing of such items as electrical junction boxes had also proved inadequate under these conditions. In general terms, the vehicles have been remarkably successful in operation, however.