Trailer checks made easy

Page 63

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

As a back-up to our normal page of equipment news, we are now running a series of tests on items that have already been featured and thought to be of special interest to operators. Trevor Longcroft kicks off the series with this evaluation of the Hope Scrutineer.

The Hope Scrutineer is made by Hope Technical Developments Ltd, High Street, Ascot, Berkshire. Price £325 plus £65 for trolley.

WHEN IT COMES to servicing, the trailer normally comes a poor second to the towing vehicle. But as the trailer is a simple piece of equipment and there are devices like the Hope Scrutineer on the market there Is really no excuse for skimping.

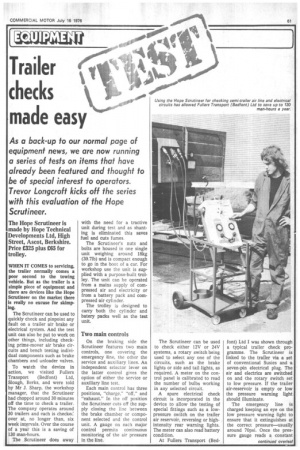

The Scrutineer can be used to quickly check and pinpoint any fault on a trailer air brake or electrical system. And the test unit can also be put to work on other things, including checking prime-mover air brake circuits and bench testing individual components such as brake 1 chambers and unloader valves. • To watch the device in action, we visited Fullers Transport (Bedfont) Ltd, Slough, Berks, and were told by Mr J. Sharp, the workshop manager, that the Scrutineer had chopped around 30 minutes off the time to check a trailer. The company operates around 30 trailers and each is checkeci over at, no longer than, six week intervals. Over the course of a year this is a saving of 130 man-hours.

The Scrutineer does away with the need for a tractive unit during test and as shunting is eliminated this saves fuel and cuts fumes.

The Scrutineer's nuts and bolts are housed in one single unit weighing around 18kg (39.71b) and is compact enough to go in the hoot of a car. For workshop use the unit is supplied with a purpose-built trolley. The unit can be operated from a mains supply of compressed air and electricity or from a battery pack and compressed air cylinder.

The trolley is designed to carry both the cylinder and batery packs well as the test unit.

Two main controls

On the braking side the Scrutineer features two main controls, one covering the emergency line, the other the service and auxiliary lines. An independent selector lever on the latter control gives the option of either the service or auxiliary line test.

Each main control has three positions, "charge," "off," and "exhaust." In the off position the Scrutineer cuts off the supply closing the line between the brake chamber or component selected and the control unit. A gauge on each major control permits continuous monitoring of the air pressure in the line. The Scrutineer can be used to check either 12V or 24V systems, a rotary switch being used to select any one of the circuits, such as the brake lights or side and tail lights, as required. A meter on the control panel is calibrated to read the number of bulbs working in any selected circuit.

A spare electrical check circuit is incorporated in the device to allow the testing of special fittings such as a lowpressure switch on the trailer air reservoir, reversing or highintensity rear warning lights. The meter can also read battery condition.

At Fullers Transport (Bed font) Ltd I was shown through a typical trailer check programme. The Scrutineer is linked to the trailer via a set of conventional Susies and a seven-pin electrical plug. The air and electrics are switched on and the rotary switch set to low pressure. If the trailer air-reservoir is empty or low the pressure warning light should illuminate.

The emergency line is charged keeping an eye on the low pressure warning light to ensure that it extinguishes at the correct pressure--usually around 70psi. Once the pressure gauge reads a constant

continued overleaf

The service line checks are carried out with the emergency line fully charged. The service line is charged to maximum in gradual stages. The gauge is checked at each stage and if the pressure reading falls, with the service line control lever in the "off" position, the brake chambers, air lines and quick-release valve must be checked for leaks.

Brake tests

The service line is then exhausted and a check made on the time for the brakes to release. Slow exhausting suggests a Sluggish brake release and a fault in the emergency relay valve.

A similar procedure is adopted for the auxiliary line check. The electrical checks are just as easy: as the rotary switch is turned through its various positions the meter throws up how many bulbs are energised in each Circuit.

Each division on the meter represents one 21-24watt bulb, so for 5-6 watt bulbs the appropriate fraction of a divi sion is used. For instance if ten 6 watt bulbs are used on a particular circuit a reading of 2.5 bulbs would be displayed if each bulb illuminated. If the meter indicates a faulty bulb it is an easy matter to walk around the trailer and identify the culprit(s).

The tolerance on bulb rat ing can vary by as much as 20 per cent and in the case of a large number of bulbs in any one circuit this can cause a reading error. However, in practice it has been found that fitters develop a good degree of read-out accuracy and quickly learn to cope with any tolerance deviations.

The Scrutineer can do many other workshop jobs. By fitting an adaptor to the Scrutineer emergency line, the device can be used to inflate tyres using the gauge to ensure correct pressures. When operating on mains electrics the Scrutineer can be used for trickle charg ing batteries, and a low voltage jack plug permits the use of a wander light or other equipment not exceeding a rating of 4 amps at 24V.

Tractor outputs on all three lines can be checked by slipping a "T"-plece into the lines connecting unit and trailer. The pressures supplied by each tine to the trailer can be read of the appropriate gauge on the Scrutineer.