A 2-3-Tonner for Long-Distance Work

Page 41

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

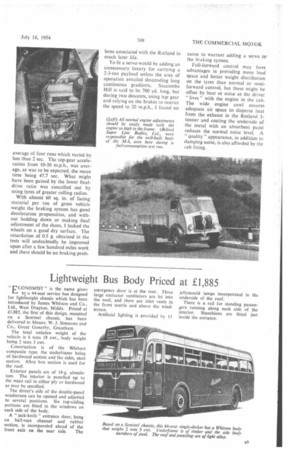

THE higher operating cost of the petrol-engined vehicle has justified the installing of an oil engine in 2-3-ton chassis where the normal work is not confined to local delivery. Most models of this class have originated from petrol-engined chassis, but the Rutland M4 is basically a derated 4-tonner and equipped initially with a fourcylindered oil engine and a fivespeed gearbox for economical medium-distance work. It has forward-control to provide adequate body space and correct distribution of load, and on continuous running over an undulating route gave a fuel consumption return of over 30 m.p.g.

Compared with other 2-3-tonners, the vehicle tested was above average weight, partly because of the wellbuilt body, made specially to the operator's requirements by Super Line Bodies, Ltd., Stratford, London, E.15, and for the sturdy frame, transmission, axles and steering gear inherited from the M.T.N. 4-tonner. Its build suggests that a 3-ton or even greater payload would be well within the capacity of the M4.

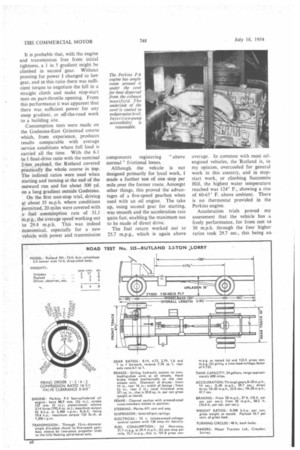

Five-speed Gearbox The Perkins four-cylindered oil engine, developing 55 b.h.p. at 2,400 r.p.m., is supported in the frame on Metalastik units. A Borg and Beck 12-in.-diameter clutch is used and a David Brown five-speed gearbox. The latter is a direct-drivetop unit, affording a maximum governed speed of 41-42 m.p.h. when the standard 7.50-20-in. tyres are fitted. In comparison with contempory models, the Rutland is generous in tyre size, which will permit continuous fast driving without danger of blow-out. A two-piece propeller shaft with Layrub type 90 couplings is used between the gearbox and axle.

Adequate retardation is provided, without requiring a servo, by using ;hoe sizes common to 5-tonners. fhe front drums are I4-in, in liameter with 2-in.-wide shoes, and tt. the rear axle a 16-in. diameter !rum is employed with 3-in.-wide hoes.

Although the vehicle was fresh rom assembly and the brake facings ot bedded in, an emergency appliation of the pedal caused rear-wheel locking and heavy marking by the front tyres. The braking system has Girling hydraulically operated units, but a vacuum-servo unit can be fitted as an optional extra.

The Rutland range is built with standard proprietary components, which is advantageous to the operator in subsequent service. The parts made by Motor Traction, Ltd., are rationalized or standardized, being basically interchangeable throughout the Rutland 3, 4, 5, 6 series, which includes the M4 3-tonner, M6 4-tonner, the Falcon 5-tonner. , and the Tucan 6-tonner. The essential differences between these chassis is in the engine size, brake servo gear and tyres, but the majority of the frame and transmission components is interchangeable. This also applies to the engine cowl which is used in

models with the Perkins P4, P6 or Meadows four-cylindered engine installed. Minor modification is made to give sufficient space at the pedals when this assembly is used i2 the M4 m'odel.

This chassis is made in I2-ft. 6-in. and 13-ft. 6-in, wheelbase lengths, the former being supplied for test with a 13-ft. drop-sided body. The vehicle has been purchased by Hadfields (Merton), Ltd., for bulk delivery of paint to sites involving.round trips of 100 miles upwards.

The test of this vehicle was not prearranged. I was in the Motor Traction works on other business when the .2-3-tonner was having a final check, after body fitting, before being delivered to the customer. There was a 2-ton load of concrete blocks available which was quickly loaded and secured against fore and aft movement, and after a rapid check in brake-shoe clearance the lorry was handed over to me for trial.

Apart from the short acceleration tests it was treated with the respect due to any new chassis, and even on the hill climbs it was driven with reserve. As freak climbs might be encountered in its normal work I tried the Rutland on the Succombs Hill l -in-5 and 1-in-41 gradients, first making a non-stop trial. and afterwards starting on the most difficult sections.

It is probable that, with the engine and transmission free from initial tightness, a 1 in 5 gradient might be climbed in second gear. Without pressing for power I changed to low gear, and in this ratio there was sufficient torque to negotiate the hill in a straight climb and make stop-start tests on part-throttle opening. From this performance it was apparent that there was sufficient power for any steep gradient, or off-the-road work to a building site.

Consumption tests were made on the Godstone-East Grinstead course which, from experience, produces results comparable with average service conditions where full load is carried all the time. With the 6.1 to i final-drive ratio with the nominal 2-ton payload, the Rutland covered practically the whole course in top. The indirect ratios were used when starting and turning at the end of the outward run and for about 300 yd. on a long gradient outside Godstone.

On the first non-stop trial, driving at about 35 m.p.h. where conditions permitted, 20 miles were covered with afuel consumption rate of 31.1 m.p.g., the average speed working out to 29.4 m.p.h. This was indeed economical, especially for a new vehicle with power and transmission components registering " above normal" frictional losses.

Although the vehicle is not designed primarily for local work, I made a further test of one stop per mile ,over the former route. Amongst other things, this proved the advantages of a five-speed gearbox when used with an oil engine. The take up, using second gear for starting, was smooth and the acceleration rate quite fast, enabling the maximum use to be made of direct drive.

The fuel return worked out to 25.7 m.p.g., which is again above

average. In common with most oilengined vehicles, the Rutland is, in my opinion, overcooled for general work in this country, and in stopstart work, or climbing Succombs Hill, the highest water temperature reached was 124° F., showing a rise of 60-65° F. above ambient. There is no thermostat provided in the Perkins engine.

Acceleration trials proved my assessment that the vehicle has .a lively performance, for from rest to 30 m.p.h. through the four higher ratios took 29.7 sec., this being an. average of four runs which varied by less than 2 sec. The top-gear acceleration from 10-30 m.p.h., was average, as was to be expected, the mean time being 47.7 sec. What might have been gained by the lower finaldrive ratio was cancelled out by using tyres of greater rolling radius.

With almost 60 sq. in. of facing material per ton of gross vehicle weight the braking system has good deceleration propensities, and without bedding down or making final adjustment of the shoes, I locked the wheels on a good dry surface. The retardation of 0.5 g. obtained in the tests will undoubtedly be improved upon after a few hundred miles work and there should be no braking prob

lems associated with the Rutland in much later life.

To fit a servo would be adding an unnecessary luxury for carrying a 2-3-ton payload unless the area of operation entailed descending long continuous gradients, Succombs Hill is said to be 700 yd. long, but during two descents, using top gear and relying on the brakes to restrict the speed to 20 m.p.h., I found no

cause to warrant adding a servo to' the braking system.

Full-forward control may have advantages in providing more load space and better weight distribution on the tyres than normal or semiforward control, but these might be offset by heat or noise as the driver " lives " with the engine in the cab. The wide engine cowl ensures adequate air space to disperse heat from the exhaust in the Rutland 3tonner and coating the underside of the metal with an absorbent paint reduces the normal noise level. A "quality "appearance, in addition to damping noise, is also afforded by the cab lining.