Many changes of mind on gearbox selection

Page 29

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

)11 MANY YEARS the most Dpular type of multispeed ansmission in use on Britain's 3avy commercial vehicles was e splitter gearbox. Until the id-Sixties, fairly modest enne outputs — both in terms of Dwer and torque — meant that )litters could double the avail1e ratios on tap literally at the ,uch of a button.

However, the advent of higher Drsepower vehicles and the .neral acceptance of rangeiange boxes has tended to iershadow the splitter.

Meanwhile, Leyland's decion to specify the American Dicer SST10 for its Roadtrain id some Constructor models )s thrown the matter into flux -ice more.

What are the differences beteen splitter and range-change Dxes and what are the advanges of each? The basic dif ference between the two types of box is the manner in which the change from main to auxiliary gearing is accomplished.

With the splitter, the driver selects, say, first gear in the low range, then to make a half gear up-change — bringing in the auxiliary gearing — he flicks a switch or presses a button and depresses the clutch.

Because there is no physical movement of a gear lever, the up change — or for that matter down change — can be achieved very quickly. Thus the gear change pattern is a straightforward one.

The Spicer SST10, as an example, is a 10-speed unit which has a twin-countershaft layout.

Twin countershafts divide the engine torque, which allows a reduction in the face width of each straight-cut, constant-mesh gear, and this in turn keeps the exterior dimensions to a minimum.

The Spicer set up is like two five-speed boxes united by two sets of primary gears. Thus the gear ratios overlap and full or half-gear selection is with either mechanical or air-shift change. In common with other splitter set-ups, the Spicer has its full changes through the main gear lever and split changes by means of a gearbox-mounted, air-operated splitter unit which is controlled by a flick switch on the gear lever.

Although the standard SST10 does not have a preselect facility — a Means by which the driver can anticipate a half change and operate the switch in advance — the Leyland application does.

Spicer says that even without a preselect, a positive change can be made every time as its box has a curvic coupling which locks with the taper under load. Each of the gear ratios is in a geometric progression and gives incremental steps of about 30 per cent throughout the range. But the Standard H-pattern layout means that the box can be used as a regular fivespeed transmission under light load conditions.

Spicer designed the SST10 for vehicles with a gross weight of 27.2 tonnes 127 tons) and over.

A high input torque capacity — 1,630Nm (1,200Ibft) — is provided by the division of the input. Efficiency is reckoned to be about 97 per cent. But one of the chief advantages of the twincountershaft design is that it is lighter and smaller than a singlelayshaft one. And this lightweight can be further improved if an alloy casing is specified instead of cast iron. This reduces the weight by 34kg (801b) while another 18kg {40Ib) can be lopped off if an alloy clutch housing is used.

Because of its large surplus input torque capacity inherent in the Spicer design (it was built for huge American vehicles with 300bhp-plus engines) the longevity is said to be good.

Spicer manufactures a range change box with up to 14 ratios but recommends this for offroad applications. For normal road use, the SST10 with its ten speeds is more than adequate, says Spicer, and its claim is that the box is simplicity itself to operate.

Certainly, during our test of the Roadtrain we found the splitter easy enough to use.

Third gear was the lowest needed for starting off from rest on level ground, then fourth gear could be skipped in favour of fifth. The splitter needed only to be used for the top three gears. However, it must be remembered that the test was at 32 tons gross and not at the Roadtrain's design weight of 40 tonnes. And its perhaps significant that the Fuller roadranger is used on those Roadtrains destined for Europe. During our test, though, whole gear changes were never any problem although the splitter was noisy and sometimes a little uncertain. Because of the sliding dog engagement of the splitter at the input end of the box it was probably this dog which caused the noise.

There are synchromesh splitter boxes such as the ZF which is fitted to vehicles like the Seddon Atkinson 300. This works on • same principle but ha smoother engagement, aided the synchronisers. One schoo thought would argue that synchromesh variety of split leads to wear on the clutch tes

The remarkable success of I ton with its Fuller Roadrani series of range-change boxes Europe has made this comps. one of the market leade supplying as it does, transrr sions to virtually every vehi manufacturer. Like its Spi. splitter counterpart, t Fioadranger series has a NI, countershaft design and t been further improved multimesh gearing. This meE that there are more teeth contrast at any one time usually two or three compai with one or two in conventio set-ups.

The Fuller range-change L is laid out in a conventional pattern, too, although in one its earlier forms the box hac dog-leg pattern. This arrani ment led to a lot of gnash' teeth when infamillar driv tried to change gear in vehic equipped with this box, as th and fourth gear positions wi juxtaposed. A further compli tion arose on the Seddon At son 400 where the pattern v inverted, too.

However, the regular Ful range-change pattern is a sim repeat double shift. In otl words, when the gear-ley mounted range-change switcl perated into high when fourth reached, first gear becomes th, second becomes sixth and on.

DriVers generally can accept is type of arrangement quite tick!), and have few problems. )wever, one difficulty which n arise is if the range-change cks in high range — someing that has happened on one W test.

Unlike the splitter set up, where it's still possible to use the regular gears, the driver is compelled to try to drive in high range only. To give more ratios, though a splitter can be added to a range change to act as a sort of overdrive for the box.

While Eaton is fairly convinced that constant-mesh rangechange boxes are the best, other makers are less sure. ZF sees a definite move to synchromesh, not only at the lower end of the weight range but on long-haul machines, too. It makes both, so presumably has no particular axe to grind.

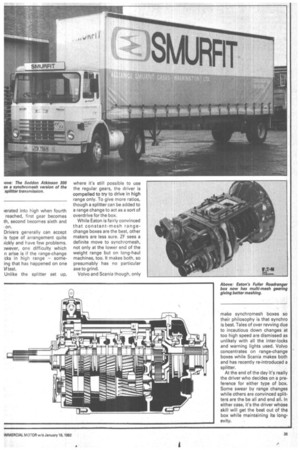

Volvo and Scania though, only make synchromesh boxes so their philosophy is that synchro is best. Tales of over revving due to incautious down changes at too high speed are dismissed as unlikely with all the inter-locks and warning lights used. Volvo concentrates on range-change boxes while Scania makes both and has recently re-introduced a splitter.

At the end of the day it's really the driver who decides on a preference for either type of box. Some swear by range changes while others are convinced Split, tett are the be all and end all. In either caSe, it's the driver whose skill will get the best out of the box while maintaining its long, evity,