A New Concept ii

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

'ractor Design

MANY entirely new design features are incorporated in the latest series of road haulage tractor units to be introduced by the G.M.C. Truck and Coach Division of General Motors Corporation, Pontiac, Michigan, U.S.A. Production of these vehicles is scheduled to start this month and they have been designed with an eye on maximum operating efficiency and high payload capacity under high-speed operating conditions on American highways.

Having been developed specifically for this type of operation, the design includes such novel departures as a fabricated steel chassis frame with I-section side members; air suspension at front and rear, with independent suspension for the front wheels; an all-aluminium tilt cab and, in the case of the heavier models, a V-6 twostroke oil engine. These new models were mentioned in the January 2 issue of The Commercial Motor, but it is now possible to give a full detailed description of the range.

Lighter Chassis Frame

For some years it has been evident that G.M.C. have been developing a special chassis frame more lightly stressed than conventional frames to take advantage of the smoother travel afforded by air suspension. 'The new G.M.C. frame weighs about half as much as a conventional assembly on an equivalent size of vehicle. Moreover, being fabricated from high-tensile • steel (S.A.E.950), it is stronger, more rigid and more durable than a conventional design, and no additional reinforcements are necessary for any application.

The use of air suspension has allowed the complete tractor units to be lightened by 6 cwt. to 18+ cwt., according to the type and specification, all of which means added payload capacity.

The new range consists of three models, two of which are merely wheelbase variations of the same basic type. The DLR 8000 tractor has a gross train weight rating of 271 tons, with a solo weight rating of 13 tons. Its wheelbase is 9 ft. and the cab is set forward so that its rear panel lies slightly ahead of the frontwheel centre line, the, front overhang being 4 ft. 2 in.

Because of the set-back wheel position, a limitation on turntable loading is imposed. hence the restriction of the gross c10 train weight rating to 271 tons. The companion models—the DFR 8000 series —have the front wheels directly under the cab and they can operate at a gross train weight of up to 34 tons with a suitable rear axle.

The standard DFR chassis has a 9-ft. wheelbase and an overall length of 13 ft. 3 in., but there is a model with a wheelbase of 10 ft. 10 in., which has the same overall length as the DLR tractor-15 ft. 1 in.

Dealing with the DLR 8000 first, the standard power unit is the General Motors 6-71 S.E. six-cylindered directinjection two-stroke oil engine, which has a cubic capacity of 6.97 litres. The gross and net power outputs are 189 b.h.p. and 175 b.h.p. at 1,800 r.p.m., whilst the gross and net torque outputs are 577 lb.-ft. and 553 lb.-ft. at 1,200 r.p.m. A 210 b.h.p. (gross) version may also be fitted.

An eight-blade aluminium fan is thermostatically controlled through a fluid coupling, so that power is not lost to it when the engine temperature is low, and the cooling system is pressurized to 7 p.s.i. Thermostatically controlled shutters enclose the radiator. Two large oilbath air cleaners are standard. Electrical equipment is 12v., the dynamo having an output of 50 amps. A 12-cu.-ft. air compressor is used.

Twin-plate Clutch

A 14-in.-diameter twin-dry-plate clutch is specified, and unit-mounted with the engine is a five-speed synchromesh gearbox with overdrive ton gear. A single propeller shaft takes the drive to a General Motors two-speed spiral-bevel rear axle with electric change mechanism. Its rated capacity is just over 8 tons, and it has ratios of 4.33 and 5.91 to 1.

The chassis frame of the DLR model has an X layout, with only two transverse cross-members in the region of the front wheels. The side members have a deep maximum section and the upper and lower flanges are of 12,-in.-thick strips machine-welded throughout their length to the main beams.

Representing a complete departure from normal G.M.C. practice, the front suspension of the DLR chassis employs unequal-length wishbones with a diaphragm air spring acting on the lower wishbones at each side. Previous G.M.C. front-suspension layouts incorporated two bellows-type springs at each side, with a tubular axle which provided additional air capacity. The extra volume is unnecessary with the diaphragm springs.

The suspension, which is controlled by a levelling valve at each wheel, is damped by direct acting telescopic shock absorbers and roll control is provided by a rubber-mounted torsion-type sway bar carried ahead of the wheels. The front suspension is rated for a capacity of just under 5 tons.

Diaphragm Rear Springs

At the rear the suspension is more akin to that formerly employed on General Motors' tractors, but here, again, diaphragm springs are used. Location is by two I-section rubber-bushed radius arms below the axle, whilst above the differential pot there are two triangulated radius arms which provide ,torque reaction and lateral location, The spring units are ahead of the axle beams and, as at the front, there are two levelling valves, and, behind the wheels, two telescopic dampers and a rubber-bushed antiroll bar.

Air-operated cam brakes incorporate 16.25-in. by 3.5-in, front units and 16.5-in. by 5.5-in, rear drums. The hand brake acts on a 12-in. by 3-in, drum at the back of the gearbox.

Tubeless tyres are fitted unless otherwise specified, 11-22.5 (12-ply) equipment being standard, with optional sizes up to 12-24.5 (12-ply). They are mounted on cast-steel-spoke wheels, although disc wheels with a 10-stud mounting are available. Twin aluminium fuel tanks are employed, giving a total capacity of 100 gal.

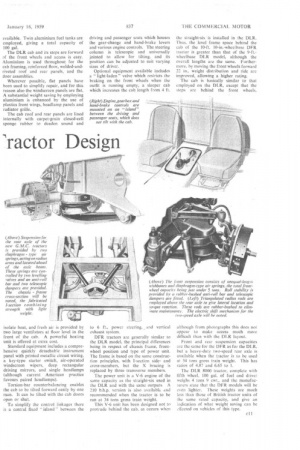

The DLR cab and its steps are forward at the front wheels and access is easy. Aluminium is used throughout for the cab framing, reinforced floor, welded-andriveted roof and rear panels, and the door assemblies.

Wherever possible, flat panels have been used to simplify repair, and for this reason also the windscreen panels are flat. A substantial weight saving by employing aluminium is enhanced by the use of plastics front wings, headlamp panels and radiator grille.

The cab roof and rear panels are lined internally with carpet-grain closed-cell sponge rubber to deaden sound and isolate heat, and fresh air is provided by two large ventilators at floor level in the front of the cab. A powerful heating unit is offered at extra cost.

Standard equipment includes a comprehensive quickly detachable instrument panel with printed metallic circuit wiring, a key-type starter switch, air-operated windscreen wipers, deep rectangular driving mirrors, and single headlamps (although current American practice favours paired headlamps).

Torsion-bar counterbalancing enables the cab to be tilted forward easily by one man. It can be tilted with the cab doors open or shut.

To simplify the control linkages there is a central fixed "island" between the driving and passenger scats which houses the gear-change and hand-brake levers and various engine controls. The steering column is telescopic and universally jointed to allow for tilting, and its position can be adjusted to suit varying sizes of driver. '

Optional equipment available includes a " light-laden " valve which restricts the braking on the front wheels when the outfit is running empty, a sleeper cab which increases the cab length from 4 ft.

to 6 ft., power steering, and vertical exhaust system.

DFR tractors are generally similar to the DLR model, the principal differences being in respect of chassis frame, frontwheel position and type of power unit. The frame is based on the same construction principles, with I-section sideand cross-members, but the X bracing is replaced by three transverse members.

The power unit is a V-6 engine of the same capacity as the straight-six used in the DLR and with the same outputs. A 210 b.h.p. version is also available and recommended when the tractor is to be run at 34 tons gross train weight.

This V-6 unit has been designed not to protrude behind the cab, as occurs when the straight-six is installed in the DLR. Thus, the level frame space behind the cab of the 10-ft. 10-in.-wheelbase DFR tractor is greater than that of the 9-ft.wheelbase DLR model, although the overall lengths are the same. Furthermore, by moving the front wheels forward 22 in., weight distribution and ride are improved, allowing a higher rating.

The cab is basically similar to that employed on the DLR, except that the steps are behind the front wheels.

although from photographs this does not appear to make access much more difficult than with the DLR layout.

Front and rear suspension capacities are the same for the DFR as for the DLR, but a heavy-duty two-speed rear axle is available when the tractor is to be used at 34 tons gross train weight. This has ratios of 4.87 and 6.65 to 1.

The DLR 8000 tractor, complete with fifth wheel, 100 gal. of fuel and driver weighs 4 tons 9 cwt,, and the manufacturers state that the DFR models will be even lighter. These weights are much less than those of British tractor units of the same rated capacity, and give an indication of what weight saving can be ffected on vehicles of this type.