Weighing trucks on the move

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

How Americans tackle vehicle weight control

British road transport operators are taking a keen look at vehicle weighing because of the heavy new penalties for overloading and the prospects of tougher enforcement. J. H. B. HORNBY has recently been to the USA and sends us this report of how one State copes with enforcement and checking.

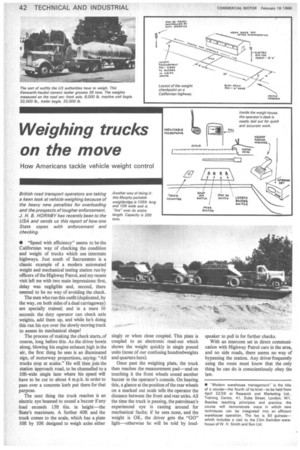

• "Speed with efficiency" seems to be the Californian way of checking the condition and weight of trucks which use interstate highways. Just south of Sacramento is a classic example of a modern automated weight and mechanical testing station run by officers of the Highway Patrol, and my recent visit left me with two main impressions: first, delay was negligible and, second, there seemed to be no way of avoiding the check.

The men who run this outfit (duplicated, by the way, on both sides of a dual carriageway) are specially trained; and in a mere 10 seconds the duty operator can check axle weights, add them up, and while he's doing this run his eye over the slowly moving truck to assess its mechanical shape!

The process of making the check starts, of coarse, long before this. As the driver bowls along, blowing his engine exhaust ,high in the air, the first thing he sees is an illuminated sign, of motorway proportions, saying: "All trucks stop at scales." He will then join the station approach road, to be channelled to a 10ft-wide single lane where his speed will have to be cut to about 4 m.p.h. in order to pass over a concrete kerb put there for that purpose.

The next thing the truck reaches is an electric eye beamed to sound a buzzer if any load exceeds 1311 6in. in height—the State's maximum. A further 40ft and the truck comes to the scale, which has a plate 10ft by 10ft designed to weigh axles either singly or when close coupled. This plate is coupled to an electronic read-out which shows the weight quickly in single pound units (none i)f our confusing hundredweights and quarters here).

Once past the weighing plate, the truck then reaches the measurement pad—and on touching it the front wheels sound another buzzer in the operator's console. On hearing this, a glance at the position of the rear wheels on a marked out scale tells the operator the distance between the front and rear axles. All the time the truck is passing, the patrolman's experienced eye is casting around for mechanical faults; if he sees none, and the weight is OK, the driver gets the "GO" light—otherwise he will be told by loud

speaker to pull in for further checks.

With an intercom set in direct communication with Highway Patrol cars in the area, and no side roads, there seems no way of bypassing the station. Any driver frequently using the route must know that the only thing he can do is conscientiously obey the law.

• "'Modern warehouse managementis the title of a course—the fourth of its kind—to be held from April 22/26 at Research and Marketing Ltd., Training Centre, 41, Duke Street, London, W1. Besides teaching principles and practice, the course will demonstrate ways in which new techniques can be integrated into an efficient warehouse operation. The fee is 50 guineas— which includes a visit to the Om Swindon warehouse of W. H. Smith and Son Ltd.