Road Tr: Part in Handling 20 Ions of Beet

Page 30

Page 31

Page 32

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

SPECIAL circumstances apply as regards the acceptance of sugar beet at the Brigg factory. It draws its supplies from an area which is limited on the northby the Humber, on the West by a line approximately five miles beyond the River Trent, on the east by the coast, and -on the south by a line from Driesey Nook to Tilbridge Lana.

Examination of a map discloses that this area is poorly served by railways, so that the factory is more dependent than usual, perhaps more so than any other sugar-beet fact* in the .country, on road transport. It is a fact that 85 per

cent, of the beet that goes into this factory must be transported by road and the balance by rail.

What this means in the way Of tonnage and demand for vehicles can be briefly quoted: The factory takes supplies from 2,450 growers cultivating 19,000 acres, so that the approximate quantity of beet which may be anticipated during the campaign is 200,000 tons. This tonnage represents approximately 80,000 lorry loads, and, assuming that 450 loads is the average per day, that allows for 66 days, or 12 weeks' work. As most people know, for various ' reasons the • campaign extends beyond that period, but the loadings at the beginning and end of the campaign are not so heavy as they are when the factory is working at full pressure. Another way of looking at the figures is this.

Assuming that each vehicle averages four journeys a day, then there is a _need for 110 to -120—individual lorries to cope with the traffic.

The point of import. aote arising from these.

figures is that the utmost endeavours have to be made to facilitate the

quick turn-round of the vehicles -so that the beet

can be delivered, con gestion reduced and unnecessary queueing, waiting, and consequent delay avoided. It has to be recorded that the authorities at this factory have done, and are doing, all they possibly can in those directions, and., their latest provision to that end is one of considerable importance.

There are three methods by which vehicles delivering sugar beet can be unloaded at the factory.. First, by hand ; secondly by having the sugar beet washed out of the lorry by means of the Elf a, and, thirdly, by tipping. The first of these, obviously, is the slowest and )east to be recommended. The second is, in itself, perhaps the quickest, but it is limited because only three jets of water are avail able and but three lorries can be unloaded at one time. It means that a certain amount of queueing up for the Ella is inevitable.

It is probably about as quick to get rid of a load of beet by tipping it, as it is by means of the Ella, but, in order to be able to reap the benefit from that facility, provision must be made for considerable numbers of lorries to be able to tip their loads simultaneously. Various means for facilitating this operation are provided at the different factories, and I have, from time to time, reported upon some of them in articles in this journal.

I think it cannot be denied that a provision of this nature, which has recently been made at Brigg, surpasses any thing which I have pre viously seen. It is certainly the most effec tive in achieving the objective of arranging that vehicles can tip their loads and get away for a fresh load in the minimum possible time.

Hauliers . accustomed to sugar-beet haulage are familiar with what I might term the conventional arrangements for unloading. Two or more fairly deep and long silos are cut and surrounded by . a low -wall. The bottom of the silo is V-shaped, so that it is deepest in the centre, and a trough is cut running the whole length of the silo into which water can be turned. The sugar beet in the silo is washed away and carried along suitable pipes into the factory, where it at once begins to be processed and converted into sugar. There is a lane between each pair of silos along which lorries line up, so that the sugar beet can be thrown out of the vehicles over the walls of the silo. This is hand unloading and is the method which, until comparatively recently, prevailed at most factories. It was slow and hard work, even when there was not much beet in the silo. When, however, the silo was,, full and the beet began to pile up inside, necessitating the throwing upwards of further supplies, the work became More difficult and the time involved was lengthened.

In addition, there was provision for only a certain number of vehicles to line up at the Side of the silo wall. This meant that there was always a long line of waiting lorries, thus aggravating the difficulty of time lost and labour expended.

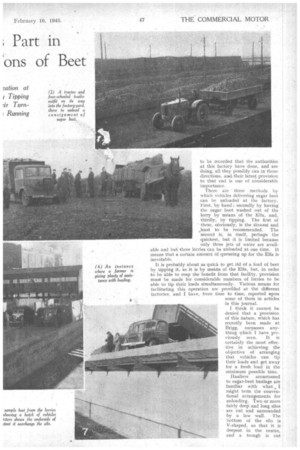

The authorities at the Brigg factory have tackled this problem in a big way' and, to my mind, have solved it most satisfactorily. A concrete platform has . been erected, -some 8 ft. or so above the level of two silos for their entire length, and wide enough to project well over each of them. The appearance of this platform is aptly described by the nickname " aircraft carrier," which was promptly given to it by the hauliers when they saw it and commenced to use it.

It is wide enough to allow tipping lorries to run on to it, turn and back to the edge along which, of course, there is a Iow wall to prevent over-running, and still leave ample ' room for vehicles to pass by while others are tipping their loads. This platform is reached by a ramp at one end and left by another at the other, one-way traffic, naturally, being the rule.

The advantage of arranging for the platform to overhang the silos is that the beet is now tipped practically into the middle of their width, so that the beet gradually heaps up in the middle and. falls away at the sides. The maximum quantity of beet can, therefore, be loaded into each silo by tipping from the platform.

° The design is excellent. The steel girder and concrete construction does not, perhaps, concern us much except as a passing point of interest in that, whereas the factory obtained priority for the steel from which the framework of the platform was to be built, it was unable to obtain it. Therefore, one of the two structures provided for railway wagons for acceptance of beet by rail was dismantled. The material from that was used to make this additional provision for acceptance of beet by road. The cost of this construction, so I was told, slightly exceeded 210,000. . That is a boon none can deny, least of all those hauliers who have tipping wagons and can use them for sugar beet. They know that, by being able to get on to this platform immediately on arrival, tip the load, and drive away again, they can ensure, at least, one more load per day over and above what would have been possible under the previous conditions. Every operator knows, too, what effect one additional load per day can be on the profit ratio of the undertaking.

Another provision at the Brigg factory, which considerably helps operators to discharge their loads of sugar beet and get away again, is made in connection with the Ella. As most sugar-beet hauliers know, the Ella washes the beet out of the lorry into a:conduit which carries it directly into the factory, there at once to begin to undergo the process of transformation into sugar. Now, normally, if for any reason there be a stoppage in the factory—and this does happen from time to time—the Ella is shut down and unloading by that process ceases.

To improve matters in that connection an ingenious arrangement prevails at the Brigg factory. Inserted into the conduit between Ella and factory there is a three-way valve, so designed that, in the event of a stoppage which, for a short time, may make it impossible for beet to be accepted, the stream of beet and water is diverted, lifted hydraulically into another large conduit running across the ends of the silos, around to the back of the railway embankment along which it runs.

At intervals along this part of the conduit, doors are placed which can be opened, separately or together. Out of these the sugar beet tumbles to form a reserve store by the side of the railway embankment and so placed that it can conveniently be taken into the factory as and when opportunity arises. The outcome of that provision is that the Elia can work continuously throughout the day, whether the factory be taking beet or not.

In view of the foregoing provisions (a) to facilitate and eneourage the use of tipping wagons, and (b) to ensure continuous working of the Elfa for which non-tipping wagons queue up, it is not surprising that but few vehicles are hand unloaded. If they be tipping vehicles they go straight to the " aircraft carrier," if they be not, they go under the Ella, and it is a fact that, at the time of my visit, only six vehicles were being hand unloaded Of that number five were, obviously, farmers' tractors hauling trailers which, of course, could not be tipped and which were unsuitable for unloading under the Ella.

Moreover, the authorities at Brigg have not overlooked

. the fact that some of the delays which used to prevail in connection with sugar-beet haulage occurred at the weighing machine. Steps have been takento reduce these. to what I think can be described as an irreducible minimum. The procedure is designed to pass the vehicle on with the least delay and no waiting for the writing-up of documents.

The lorry Hi as on to the weighbridge and the driver hands in. his permit. Meanwhile, the weight is being taken and recorded on a weighbridge ticket, which is then attached to the permit.. Tare and test counterfoils are detached ;and handed to the driver, who, in the meantime, has either been handed a sample bucket or has taken one front a heap .which lies conveniently .near to the weighbridge.The tare and test ticket is put into a Container on the side of the sample bucket and the driver goes on his way.

In the interim, between him leaving the weighbridge with' a full load and coming back to have the vehicle weighed enipty, the other essential information as to the name of the farmer, etc., is entered on the'weighbridge ticket, so 'that it is ready for the driver when he returns.

The weight of the empty lorry is automatically recorded as it runs on to the weighbridge, and the essential informa. tion, namely, the difference between the laden weight and the unladen weight, giving as a balance the weight of beet plus dirt delivered, is available.' Incidentally, the time in and time out are also stamped on the weighbridge ticket, and that information is avail

able for future use in case of some question arising as to the-time the lorry .was kept waiting. So expeditiously is this work at the weighbridge carried out that it is quite customary for upwards of 50 vehicles an hour to pass and, in times of heavy-presstire, as many as 60 have gone over the weighbridge in-the hour. _.

The point meelioned 'about balance—the difference between the laden and unladen weights-4 the weight of beet plus dirt delivered, and is of sufficient importance to 'justify' amplification.

Reference has been made to the tare and test-tickets which' are detached from the weigh ticket and handed -to the driver: These are slipped.into a little receptacle on the side of the sample bucket: The -driver takes the sample _bucket with him and, after a few beet have been discharged from the rear of his lorry, the bucket is filled with a repre

senMtiVe sample of the load he has brought. . _ •

This -bucket is -then taken into the tare and test room. The contents are first thoroughly_ washed for five minutes. The beet is then transferred to a clean bucket, the tare and-test ticks i'oeing also transferred from the first bucket

to the second _ •

, Any "-kips ". still left on the beet are cut off, and after that is done thea net weight of clean beet, that is the original beet, less dirt which has been washed. off and " tops" which have been cut off, is taken. In the sample I saw; the net weight was 24 A. out of the original 28 lb.

That is not all the provision which is made -for arriving at the quantity of dirt in a load. It is recognized, and should be obvious, that when a load of beet is tipped, or when it. is _washed out under the Elfa, practically all the dirt as well as the beet is conveyed into the factory, whereas, if the beet be hand unloaded, a considerable proportion of the dirt lies in the bottom, of the lorry and gets carriedaway again, thus being inrhided in the weight of the empty lorry as it passes over the weighbridge for the secOnd time.

As the Sugar Beet Corporatiort seems to have some objection to paying high prices for dirt, provision is made for the extra allowance Of dirt to be made in connection with beet which is tipped or wasted out of the vehicles. That aniount is 2 lb. per cwt.

When the sample is taken, the man taking the sample knows by what process the beet is to be unloaded. If it be tipped he marks figure 2 in blue pencil; if it be washed he marks the figure 2 in green pencil. That indicates to the accountant's department that 2 lb. must be added to the proportion of dirt which has been found to be present with the beet during the examination and 'weighing as just described.

For example; I have stated that, in the case of the sample I followed through the works, the net weight of clean beet was 24 lb. That is 96 lb. per cwt. This would be reduced by 2 lb. and the farmer-allowed 94 lb.. per cwt. of beet

plus dirt as it passed over the weighbridge.

In the case of beet which is neither tipped nor washed but is hand unloaded, provision, to note that is also marked on the ticket, and the 'farmer is given an allowance of 3d. per ton on that account.

It is of interest to note that there is a representative of the National Farmers' Union always present in the factery, who checks the results of washing and weighing and the chemical process for ascertaining the percentage of sugar in the beet, so that both farmer and factory are mutually satisfied that the allowances are correct.

The necessity of checking the percentage of sugar in. the beet should be fairly manifest, but it is 'perhaps of interest to note that the standard rate per cwt, which is agreed is paid in the case of beet in which the percentage 'of sugar is 15.5. ..For every 0.1 per cent, above that standard the farmer receives an additional 4d. ' For every point. 'below it, 4d. is deducted from the standard rate.

An important thing to recall in connection with the haulage of sugar beet is' that it is not ehtirely a one-way traffic, as the following figures will show. For every ton of clean beet coming into the factory 14 cwt. Of available as a back load to the farmer, and that back load is particularly important to him just now because he iiies it as cattle food and it is" off the ration."

A point to note about the pulp is that it is. liiht in relation to its bulk, so that only 4-4.1 tons can be carried in an ordinary 6-7-ton lorry. Further, farmers and hauliers are urgently 'requested by the factory not to leave the collection of pulp, until the end of each current -month, because that procedure causes congestion and delay. -•

Another outward load from the factory is, of course, sugar, and although some of that goes by road it is important to remember that the weight of sugar is approximately 3 cwt. per ton Of beet.

• Finally, there is the carbonate of lime which is a by-product of the manufacturing process and is useful to farmers to put on' their fields.

Adding it up in this way, we arrive at some interesting figures for tonnages. For 200,000 tons of beet the outward loadings are, approximately, 30,000 tons of sugar, 15,000 tons of pulp and 15,000 tons of carbonate of lime.