CONCERNING STEAM VEHICLES.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Fittings and Maintenance Ideas Suggested by Our Driver and Mechanic Readers.

WEAR in the steering mechanism is at all times unpleasant, as it involves lost motion which has its direct effect upon . the ease of handling the vehicle on the road. For an ingenious repair in connection with the steering of his vehicle, this week's prize of Isis. is awarded to "W.J.H.," of London' W.6. When dismantling, "W.J.14." found that the top bracket of the steering column had worn oval. This bracket was inside the coal and coke bunker, and the column passed right through the bunker itself, another fact which helped to make steering difficult, as the fuel rubbed against it.. To overcome the trouble economically, he obtained a steel boiler tube having an internal diameter such that it was a good fit over the steering column. The upper bracket was drilled out to accommodate the tube, and the hole in the bottom of the coal bunker was similarly dealt with. The boiler tube was so fitted that its large end was at the top andserved the purpose of an oil well, thus lubricating the whole column and increisiag its efficiency. A stay Was made which was bolted to the end of V the hunker and clipped round the --upper end of the boiler tube. .Mounted on this Stay was a bracket supporting a lubricator which fed the steering column.

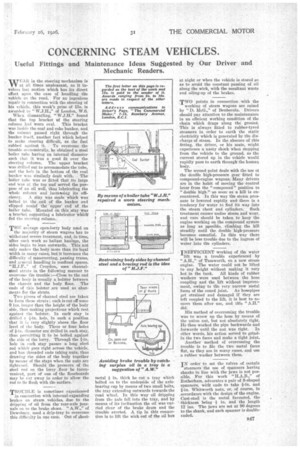

THE as erage open-lorry body used on the majority of steam wagons has to withstand severe treatment, and, in time, after such work as ballast haulage, the sides begin to lean outwards. This not only makes the body more than its legal width in many cases, but it increases the difficulty of manmuvring, passing trams, and general handling, in confined spaces. "H.S.F.," of Croydon, uses channelsteel struts in the following manner to overcome the trouble •:—Close to the end of the body is usually a bolster between the chassis and the body floor. The ends of this bolster Are used as abutments for the struts.

Two pieces of channel steel are taken to form these. struts;, each is cut off some 9 ins, longer than the height of the body side, thus making projections which rest against clue bolster. In each stay is

drilled a hole, in such a position that it i very slightly above the floor level of the body. Three or four holes of fin, diameter are drilled in each stay, thus permitting it to be bolted against the side of the lorry. Through the 1-in. hole in each stay passes a long steel rod which goes right across the, vehicle, and has threaded ends taking nuts, thus drawing the sides of the body together by means of the stays when the nuts are tightened. Should the presence of the steel rod on the lorry floor be inconvenieet, part of one of the floorboards may be cut away in order to allow the rod to lie flush with the surface.

TROUBLE is sometimes experienced

in connection with internal-expanding brakes on steam vehicles, due to the dripping of oil from the-retusaxle journals on to the brake shoes. " A.W.," of Dewsbury, used a drip-tray to overcome this difficulty in one case. Out of sheet metal * in. thick he cut a tray which bolted on to the underside of the axlebearing cap by means of two small bolts, the tray extending outwards towards the road wheel. In this way oil dripping from the axle fell into the tray, and by means of its inclination the oil was carried clear of the brake drum and the trouble averted. A tip in this connection is to lift the wick out of the oil box

at night or when the vehicle is stored so as to avoid the constant passing of oil along the wick, with the resultant waste and oiling-up of the brakes.

TWO points in connection with the working of steam wagons are raised by "D. MeG.," of Benbecula. Drivers should pay attention to the maintenance in an efficient working condition of the chain which drags along the ground. This is always fitted to rubber-tyred steamers in order to earth the static electricity which is generated by the discharge of steam. In the absence of this fitting, the driver, or his mate, might experience a nasty shock when stepping from the vehicle to the ground, as the current stored up in the vehicle would rapidly pass to earth through the human body.

The second point deals with the use of the double high-pressure gear fitted to compound-engine wagons. Many drivers are in the habit of moving the control lever from the, "compound" position to "double high" so soon as a hill is encountered. In this way the steam pressure is lowered rapidly and there is a tendency for water to find its way into the steam chest and cylinders. Such treatment causes undue stress and -wear, and care should be taken to keep the engine working on the compound system as lung as passible, climbing the hill steadily until the double high-pressure becomes essential. In this way there will be less trouble due to the ingress of water into the cylinders.

INEFFICIENT working of the water lift was a trouble experienced by " A.EL," of Tamworth, on a new steam engine. The water could not he lifted to any height without making it very hot in the tank. All kinds of rubber washers were used between the hose coupling and the lift without improvement, owing to the very narrow metal bums of the coned joint. As hosepipes get strained and damaged if they are left coupled to the lift, it is best to remove them after use, and this " A.H." did.

His method of overcoming the trouble was to screw up the hose by means of the union nut, but not absolutely tight. He then worked the pipe backwards and forwards until the nut was tight. In other words, his action served to grindinthe two faces and make a tight joint.

Another method of overcoming the trouble is to file the two metal faces fiat, as they are in many cases, and use a rubber washer between them.

IN order to set the valves of certain steamers the use of spanners having shanks in line with the jaws is not possible. For this work "H.A.B.," of Rotherham, advocates a pair of S-shaped spanners, with ends to take fin. and Whitworth nuts, or, of course, in ,accordance -with the design of the engine. Cast-steel is the metal favoured, the thickness being in. and the length 12 ins. The jaws are set at 90 degrees to the shank, and each spanner i$ doubleended.