A NUBIAN for

Page 46

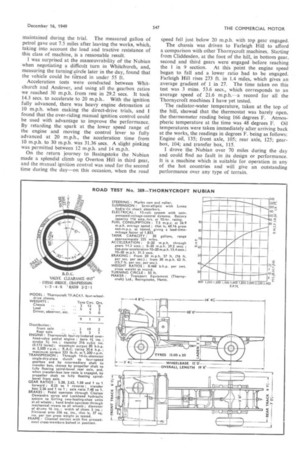

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

A ROMAN HOLIDAY

BY L.J.COTTON M.I.R.T.E

NUBIANS, highly prized as slaves in the courts of the Cresars, are in their modern mechanical form no less willing servants. The Romans were, however, notoriously savage in their pleasures, despite their classic civilization, and the sacrifice of a slave to make a holiday was solid enjoyment. My treatment of the Thornycroft Nubian at Farnborough was no less than brutal, and my enjoyment unashamed, With such a precedent before me, how could I be blamed?

The Thornycroft Nubian must also be recognized as a warrior, because 4,500 chassis of this type were made during the war and used by the Services in all parts of the world. There has been one slight modification to a gearbox bush and a change from magneto to coil ignition since the prototype was produced but, apart from these, no other alteration has been made. This model is now enjoying popularity as a cross-country fire-tender chassis, and as a load carrier overseas.

It is available with a petrol or oil engine, the test chassis being equipped with a foureylindered overhead-valve petrol engine, which develops 85 b.h.p, at 2,500 r,p.m. and 223 lb.-ft. torque at 1,20r) r.p.m. This unit is of compact design and embodies few departures from orthodox practice. It has a cast-iron crankcase and cylinder block forming a monobloc casting, and press-fit dry cylinder liners. The crankshaft is counterbalanced and the five mainbearing journals run in precision-fit steel-backed white-metal-lined hearings. White metal is run direct into the big-end bearings. Split-skirt aluminium-alloy pistons are fitted and equipped with fully floating gudgeon pins.

The camshaft is carried in three plain phosphor-bronze bearings, and operates the valverocker gear through mushroom-headed tappets and push-rods. The rockers are mounted above the one-piece detachable head and operate the valves, which are offset to the piston centre. Stellite inserts are used for the exhaust-valve seatings.

Bee2 use of the height of the crankshaft above ground level, a normal starting handle engaging directly on the shaft would be out of reach for cranking purposes. To overcome this difficulty, the Nubian is equipped with a chain sprocket attached to the starting-dog spindle, and below it is a corresponding sprocket for a chain drive to the starting-handle spindle. When the starting handle is pushed inwards, the movement is transmitted to the starting dog through a pair of toggle levers and causes the dogs to engage. A spring between the lower sprocket and chain-drive casing disengages the dogs when the engine starts.

To provide a straight-line transmission between the engine, gearbox and transfer box, the engine is inclined on its mountings. At the front of the power unit a bridge-piece extension rests between two rubber pads and is held in position by collars and bolts. The rear mounting on each side of the clutch housing comprises angle brackets bolted to the housing and resting upon Silentbloc bushes surrounding the main support bolts.

Bolted directly to the flywheel housing, the main gearbox case is made of cast iron. The transfer box, for distribution of the drive from the main gearbox to both axles, is flexibly supported at the centre of the chassis. It is connected to the main gearbox by a Hardy Spicer jointed shaft, and is arranged for both axles to be driven when the auxiliary low gear is engaged.

When the auxiliary-box high ratio (direct drive) is engaged, the transmission to the front axle is disconnected and only the rear wheels are driven. The ground clearance of the transfer box, that is, the belly clearance of the chassis, is 1 ft. 6i ins.

Both axles are of fully floating pattern, and have a spiral-bevel drive to the differential unit. The final drive is at the wheel hubs, which contain epicyclic-gear reductions, driven direct from the axle shafts. The combined reduction of bevel and epicyclic gear is 7.48 to 1. The front wheels are driven from the axleshafts through double universal joints, giving constant velocity at all angles of steering lock.

All four wheels are braked through a Lockheed hydraulic system boosted by a Clayton Dewandre vacuum servo. The shoes are wedgeactuated, and as the width of the shoes and diameter of drums are the same at all four wheels, they are interchangeable.

Although the frame sideand cross-members are of pressed-steel channel section, forming a robust structure, the chassis has the required flexibility for cross-country operation.

I met the test chassis at Pinehurst Barracks, Farnborough, and because of local fog decided to test the brakes before proceeding to the Tank proving ground. There is a level stretch of concrete-surfaced road within the compound, which proved ideal for these tests. A series of runs at 30 m.p.h. produced an average stopping distance of 62 ft., corresponding to an efficiency of 48 per cent., which is adequate for a machine of the cross-country category. A subsequent " spot " brake test made later in the day, after the chassis had been through mud and water, showed an improvement in efficiency, the chassis being brought to rest from 30 m.p.h. in 53 ft.

Occasion for Full Traction

I drove on to the soft surface of the proving ground with direct drive engaged in the transfer box, and the chassis slowed to a standstill as the tractive effort increased. I tried racing the engine and slipping the clutch, but the chassis would not move. This was a good point, because I had to engage the auxiliary-low

ratio, which brought the front-wheel drive into action, before the test could be continued. I term this a good point because an inexperienced driver, handling a chassis on this surface, could easily bog down the rear wheels when driving on only one axle when ground conditions demanded four-wheel drive.

There had been heavy rain on the day preceding the test and many of the holes and furrows of the wellchurned ground were filled with silt and mud, which proved admirable for testing a cross-country machine.

selected second-gear auxiliary-low ratio for the trial and headed the Nubian into the morass. I have tested Tanks under such conditions and have been showered with mud through the porthole as the Tank dipped into the furrows. I was spared this unpleasantness when driving the Thornycroft and proceeded to plunge through mud and water without being splashed.

The chassis put up a creditable performance, when ploughing through mud, clay and water and climbed out of ditches without a trace of wheel spin. The tracks left behind by the bar-tread tyres were clean and positive. Of course, the width of the tyres and balanced loading between axles helped to prevent wheel

slip. There were many occasions when the chassis was poised at an alarming angle and when driving obliquely up mud-covered slopes there was no tendency towards side slip.

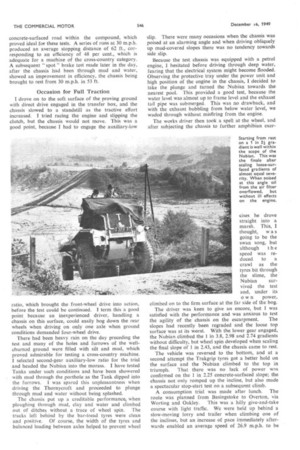

Because the test chassis was equipped with a petrol engine, I hesitated before driving through deep water, fearing that the electrical system might become flooded. Observing the protective tray under the power unit and high position of the engine in the chassis, I decided to take the plunge and turned the Nubian towards the nearest pool. This provided a good test, because the water level was almost up to frame level and the exhaust tail pipe was submerged. This was no drawback, and with the exhaust bubbling from below water level, we waded through without misfiring from the engine.

The works driver then took a spell at the wheel, and after subjecting the chassis to further amphibian exer

cises he drove straight into a marsh. This, I thought, w a s going to be the swan song, but

although t h e speed was reduced to a crawl as the tyres bit through• the slime, the Nubian survived the test and, under its o w n power, climbed on to the firm surface at the far side of the bog.

The driver was keen to give an encore, but I was satisfied with the performance and was anxious to test the agility of the chassis on the escarpment. The slopes had recently been regraded and the loose top surface was at its worst. With the lower gear engaged, the Nubian climbed the 1 in 3,8, 2.98 and 2.74 gradients without difficulty, but wheel spin developed when scaling the final slope of 1 in 2.43, and the chassis came to rest.

The vehicle was reversed to the bottom, and at a second attempt the Trakgrip tyres got a better hold on the surface and the Nubian climbed to the top in triumph. That there was no lack of power was confirmed on the 1 in 2.25 concrete-surfaced slope; the chassis not only romped up the incline, but also made a spectacular stop-start test on a subsequent climb.

A consumption trial was made after lunch. The route was planned from Basingstoke to Overton, via Worting and Oakley. This was a hilly give-and-take course with light traffic. We were held up behind a slow-moving lorry and trailer when climbing one of the inclines, but an increase of pace immediately afterwards enabled an average speed of 26.9 m.p.h. to be maintained during the trial The measured gallon of petrol gave out 7.5 miles after leaving the works, which, taking into account the load and tractive resistance of this class of machine, is a reasonable result.

I was surprised at the manceuvrability of the Nubian when negotiating a difficult turn in Whitchurch, and, measuring the turning circle later in the day, found that the vehicle could be tilrned in under 55 ft.

Acceleration tests were conducted between Whitchurch and Andover, and using all the gearbox ratios we reached 30 m.p.h. from rest in 29.2 secs. It took 14.3 secs. to accelerate to 20 m.p.h.. With the ignition fully advanced, there was heavy engine detonation at 10 m.p.h. when making the direct-drive trials, and I found that the over-riding manual ignition control could be used with advantage to improve the performance. By retarding the spark at the lower speed range of the engine and moving the control lever to fully advanced at 20 m.p.h., the acceleration time from 10 m.p.h. to 30 m.p.h. was 31.36 secs. A slight pinking was permitted between 12 m.p.h. and 14 m.p.h.

On the return journey to Basingstoke the Nubian made a splendid climb up Overton Hill in third gear, and the manual ignition control was used for the second time during the day-on this occasion, when the road speed fell just below 20 m.p.h. with top gear engaged.

The chassis was driven to Farleigh Hill to afford a comparison with other Thornycroft machines. Starting from Cliddesden, at the foot of the hill, in bottom gear, second and third gears were engaged before reaching the 1 in 9 section. At this point the engine speed began to fall and a lower ratio had to be engaged. Farleigh Hill rises 273 ft. in 1.4 miles, which gives an average gradient of 1 in 27. The time taken on this test was 3 mins. 53.6 secs., which corresponds to an average speed of 21.6 m.p.h.-a record for all the Thornycroft machines I have yet tested.

The radiator-water temperature, taken at the top of the hill, showed that the thermostat was barely open, the thermometer reading being 166 degrees F. Atmospheric temperature at the time was 48 degrees F. Oil temperatures were taken immediately after arriving back at the works, the readings in degrees F. being as follows: Engine oil, 135; front axle, 105; rear axle, 125; gearbox, 104; and transfer box, 115.

I drove the Nubian over 70 miles during the day and could find no fault in its design or performance. It is a machine which is suitable for operation in any of the hot countries and will give an outstanding performance over any type of terrain.