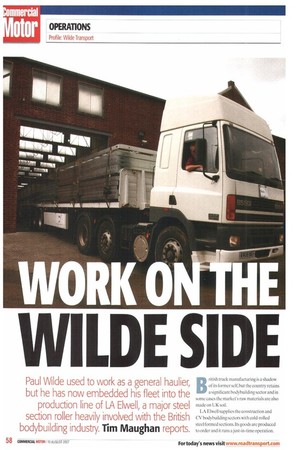

Paul Wilde used to work as a general haulier, but

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

he has now embedded his fleet into the production line of LA Elwell, a major steel section roller heavily involved with the British bodybuilding industry. Tim Maughan reports.

British truck manufacturing is a shadow of its former self, but the country retains a significant bodybuilding sector and in some cases the market's raw materials are also made on UK soil.

LA Elwell supplies the construction and CV bodybuilding sectors with cold-rolled steel formed sections. Its goods are produced to order and it runs a just-in-time operation. Processed stock is taken from one of its two factories, in Wolverhampton and West Bromwich, and dispatched direct to customers. For this reason it has a road haulage company at its Wolverhampton site: Wilde Transport (UK), a four-truck fleet (soon to be six) run by Paul Wilde.

Steve Harding,joint MD at Elwell, explains what the manufacturing process entails. One of the first things he stresses is how steelsection rolling has changed. Years ago it could take six hours to change rolls to fashion a section, now it can he done in five minutes. "Everything here is cut to size," he adds.

A number of production lines are in action as CM tours the factory. One of these lines, along with its range of specialist machinery, cost £im to install.

A Framemaster machine is deftly knocking out steel sections destined for a university building.This is a seamless operation, where end customer and fabricator liaise closely. Elwell even has the plans for the university build, which means it can produce the materials in sequence before they are hauled to the site by Wilde Transport.The building's designer, based in Leeds, e-mails Elwell directly so sections can be rolled as needed.

Elwell is also making steel sections for officers' quarters for the MoD.

"Everything is just in time," Harding stresses. "Anything they want tomorrow, they get tomorrow."

He shows us a 3x3rn frame—the

now it

manufacturing process ensures that structures of this size are made to within a millimetre.

British made — Indian owned

Much of the raw material used is from Corus now Indian-owned, even though its wares are forged in the UK — and the gantry crane that soars above bears the name John Smith, showing this is another British-made product. Four of these cranes operate at the site.

Production director David Haycock says the Wolverhampton facility has a shopfloor workforce of 32:at West Bromwich there are 41 production workers.

But all this activity is futile without Wilde Transport. CM watches as one of Wilde's flats is loaded. Because the consignments are fashioned, rather than raw commodities, there is a lot of air between the individual sections Harding and Haycock explain that a full load on a 44-tonner only weighs in at 10 tonnes.

This is a fast-moving environment, where products tend to be promptly whisked away from site, and Elwell demands utterly reliable and conveniently placed haulage services, Occasionally, stock is held at Elwell sites "People like to cool off, sometimes," says Harding but the focus remains on getting steel sections away quickly.

The firm has always been heavily involved with CV manufacturing. Bodybuilders take 40% of its products and 40% of the goods are destined for the construction sector.The rest goes into a number of other areas. "Road transport has always been our core business, but a lot of bodybuilders have come and gone," says Harding.

Elwell also makes load-restraint gear for the UK market,and exports to Germany, Holland, Spain,Sweden and even New Zealand. But one market has been lost,as Harding explains:"The strong pound and the weak dollar mean we are no longer competitive in the United States."

Better than average margins

Despite an unforgiving international market the firm manages to make a decent profit, turning over £20m with margins hovering between 7 and 10%.

Corus's own fleet brings in the raw materials. while Wilde's trucks drop steel sections at construction sites and bodybuilders.The LOV CM sees is bound for the university site in Uxbridge.All the sections are marked to show where they will fit into the final structure. Because they are rolled, and dropped, in sequence,Wilde's team has to ensure consignments are correctly loaded.

He is accustomed to the complexities of the job: "Before this I was working with the automotive industry doing timed deliveries to a car factory."

Harding adds:"Because we have so many timed site deliveries, it is important that we have a reliable haulier."

Elwell's Wolverhampton site is Wilde Transport's official operating centre.This benefits both parties, because it means Wilde is not burdened by accommodation overheads, while Harding has vehicles on tap. Elwell and Wilde are bound by a formal agreement.

With such a strong link in place, Wilde Transport is sheltered from the brutal hire-or-reward environment.There is "no comparison" between the two arenas, says Wilde: -There is enough on my plate here." Harding's local area is still a major steel rolling centre: "The Black Country is still the centre of steel section rolling in Britain,spread across a 10-mile radius, where 80% of our competitors are based.And the infrastructure and supply lines are in place to support it."

Only the best will do

Wilde may not have to compete against other hauliers. or chase backloads, but he does have to maintain a first-rate operation in order to fulfil his commitments to Elwell. He employs a litter to ensure vehicles are kept in tip-top condition. Elwell will be involved in the London Olympics building project, which means Wilde LOVs will have to enter the congested M25 zone time and again."If that's what the market demands, you have got to give the service," he says.rIbe firm is paid on a load basis. "It is not a picnic," he adds, "but it's what you set yourself up for. It's a reliable source of work."

As Elwell continues to grow, Wilde says he will expand his fleet accordingly. It can be relatively quiet during the summer and Christmas holidays, hut all told Wilde enjoys relatively steady workflows."It is not that lumpy for us," he concludes.