The Cummins V555 saves 6001b

Page 66

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

BASED on an engine developing 240 bhp at 3300 rpm, a Cummins oversquare V8 diesel new to Britain is derated to 225 bhp at 3000 rpm to give a longer life and improve durability. It has a longer stroke than the V-504 21013hp unk.

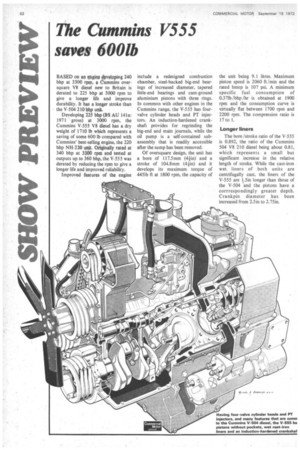

Developing 225 bhp (BS AU 141a: 1971 gross) at 3000 rpm, the Cummins V-555 V8 diesel has a dry weight of 1710 lb which represents a saving of some 600 lb compared with Cummins' best-selling engine, the 220 bhp NH-220 unit. Originally rated at 340 bhp at 33.00 rpm and tested at outputs up to 360 bhp, the V-555 was derated by reducing the rpm to give a longer life and improved reliability.

Improved features of the engine include a redesigned combustion chamber, steel-backed big-end bearings of increased diameter, tapered little-end bearings and cam-ground aluminium pistons with three rings. In common with other engines in the Cummins range, the V-555 has fourvalve cylinder heads and PT injectors. An induction-hardened crankshaft provides for regrinding the big-end and main journals, while the oil pump is a• self-contained subassembly that is readily accessible after the sump has been removed.

Of oversquare design, the unit has a bore of 117.5mm (4-kin) and a stroke of 104.8mm (4I-in) and it develops its maximum torque of 4451b ft at 1800 rpm, the capacity of the unit being 9.1 litres. Maximum piston speed is 2060 ft /min and the rated bmep is 107 psi. A minimum specific fuel consumption of 0.371b/bhp/hr is obtained at 1900 rpm and the consumption curve is virtually flat between 1700 rpm and 2200 rpm. The compression ratio is 17 to 1.

Longer liners

The bore /stroke ratio of the V-555 is 0.892, the ratio of the Cummins 504 V8 210 diesel being about 0.81, which represents a small but significant increase in the relative length of stroke. While the cast-iron wet liners of both units are centrifugally cast, the liners of the V-555 are 1.5in longer than those of the V-504 and the pistons have a corrrespondingly greater depth. Crankpin diameter has been increased from 2.5 in to 2.75in.

The cam-turned piston skirt has a ;mooth finish and a slight taper below he ring belt, the metal being relieved n the gudgeon-pin area to reduce 'eciprocating weight. Made of ductile ron, the top compression ring is of he chrome-plated barrel-faced grooved-back keystone type, the kecond compression ring being of the :hrome-plated cast-iron taper-faced grooved-backed rectangular type. The Dil-Control ring is also of ductile iron, is backed by a coil-type steel expander and is chrome-plated on its inner face as well as the outside to reduce friction between the ring and the expander.

Following the example of the V-504 the pistons of the V-555 have crowns without valve pockets and this is conducive to effective swirl control, the elimination of pockets having been made possible by the use of a camshaft providing minimum valve overlap consistent with good volumetric efficiency. A contoured swirl plate under each of the two inlet-valve seats promotes the necessary air swirl in the combustion chamber, which has a diameter of 3.15in. Peak cylinder pressure of both engines is 1300 psi, but heat rejection to the cooling water is substantially lower in the case of the V-555.

Special attention has been given to cooling, the water flow being equally divided between the two cylinder blocks controlled by a single modulating by-pass thermostat located at the front of the engine on the right

The water circulates from ' the outside of each bank around each cylinder to the head with a flow rate of about 80gal /min. An oil cooler of the bundled-tube type is connected in parallel with the cooling system.